Vertical lifting device and method

A technology of vertical hoisting and hoisting rope, applied in portable hoisting devices, hoisting equipment braking devices, safety devices, etc., can solve the problems of simple facilities, low efficiency, poor safety, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

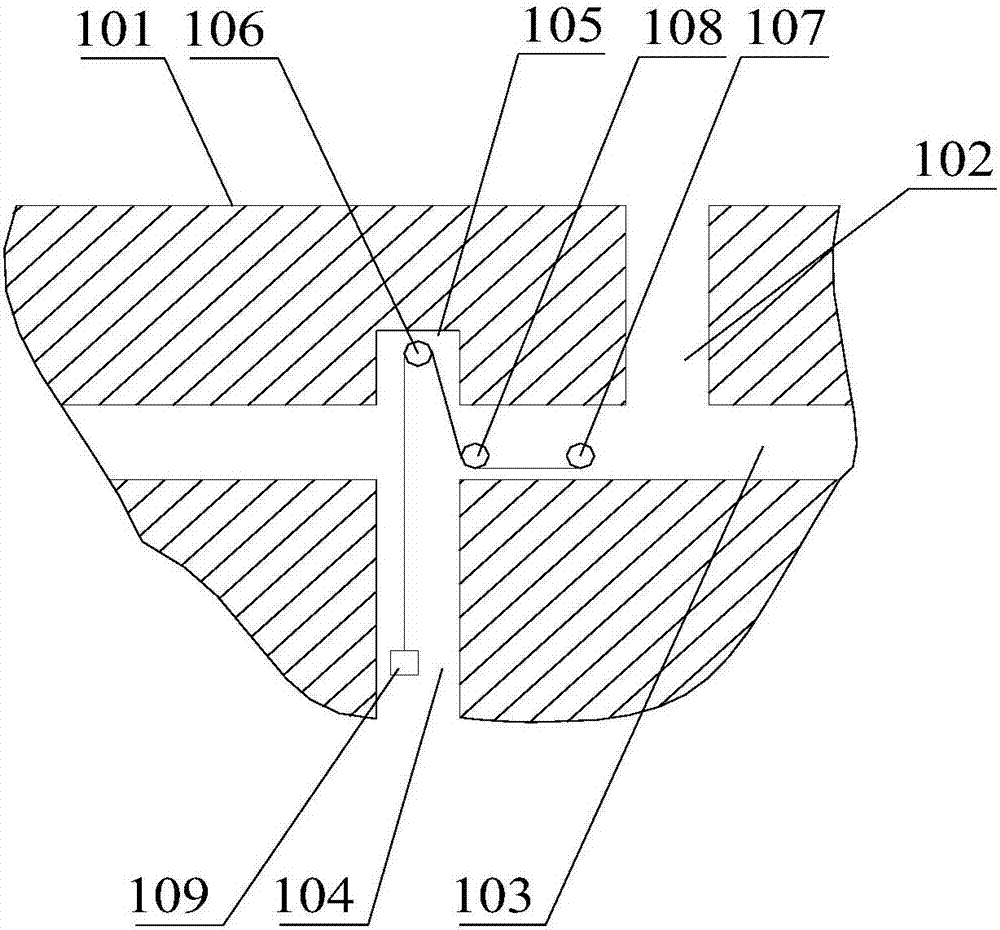

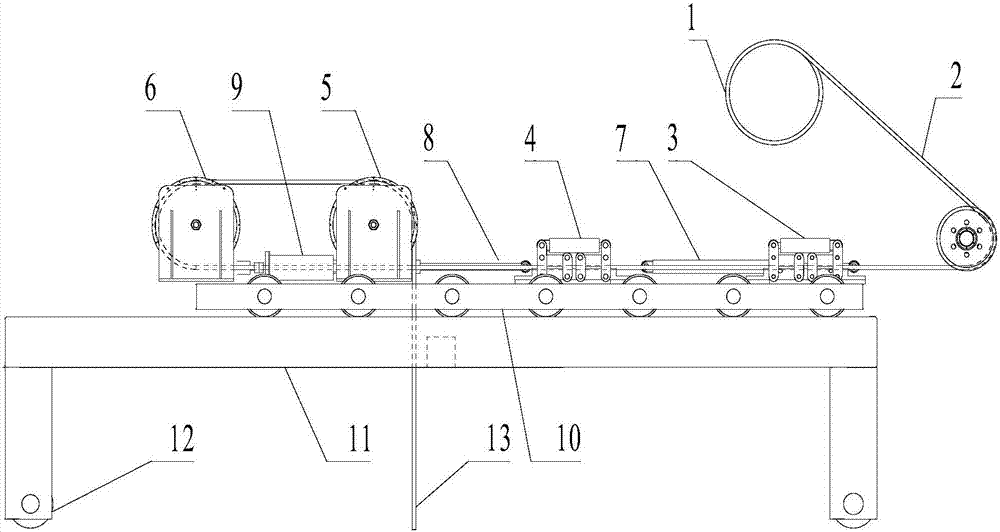

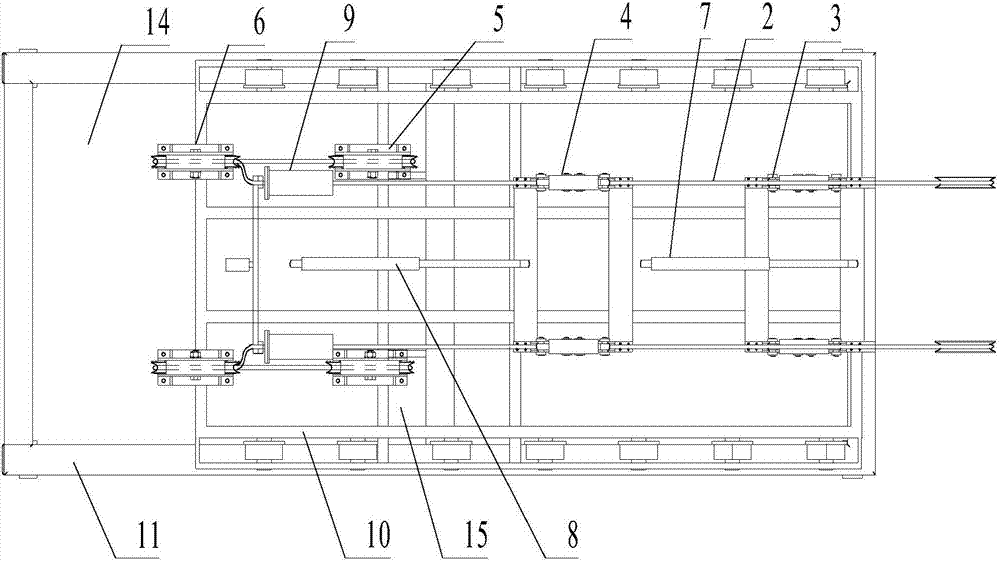

[0037] The embodiment of the present invention provides a vertical lifting device, which includes a fixing frame fixed to a foundation, and a first cavity for accommodating a hoisting rope is provided in the middle of the fixing frame; The sliding frame moves horizontally, and a second cavity is provided in the middle of the sliding frame to accommodate the passage of the lifting rope; the sliding frame is provided with at least two stepping vehicles that alternately lower or lift heavy objects, each The stepping car moves on the sliding frame with a preset distance between each stepping car; the hoisting rope passes through each stepping car in turn, and each stepping car is provided with a clamp for clamping the hoisting rope Components and a driving mechanism for driving the stepping car to move on the sliding frame.

[0038] The principle of the embodiment of the present invention is: through the mutual cooperation of the fixing frame and the sliding frame, the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com