Power distribution cabinet body grinding device

A cabinet body and equipment technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of uneven cabinet body, low work efficiency, and poor grinding effect of stainless steel plates, etc., so as to achieve a convenient working environment, Easy to polish effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

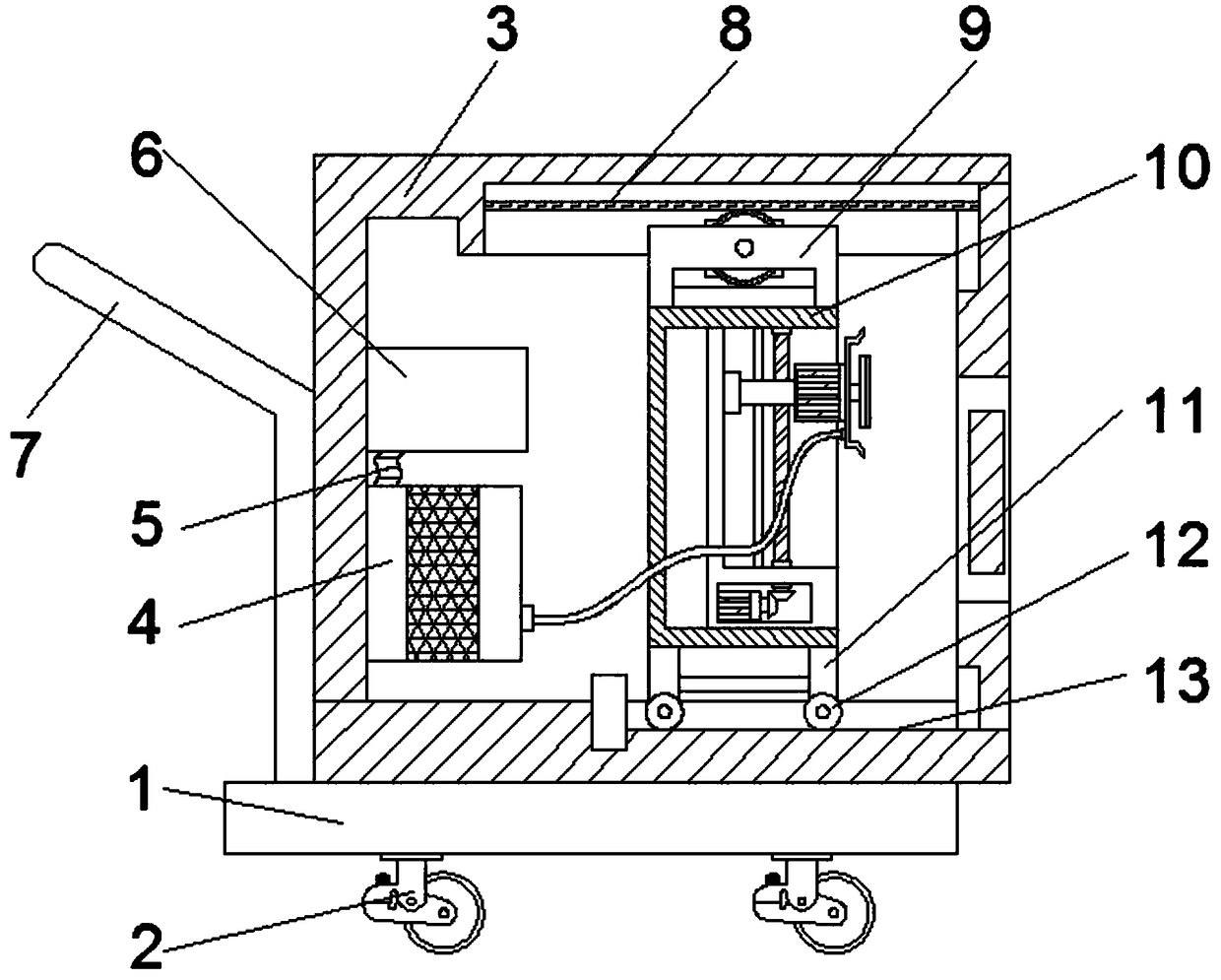

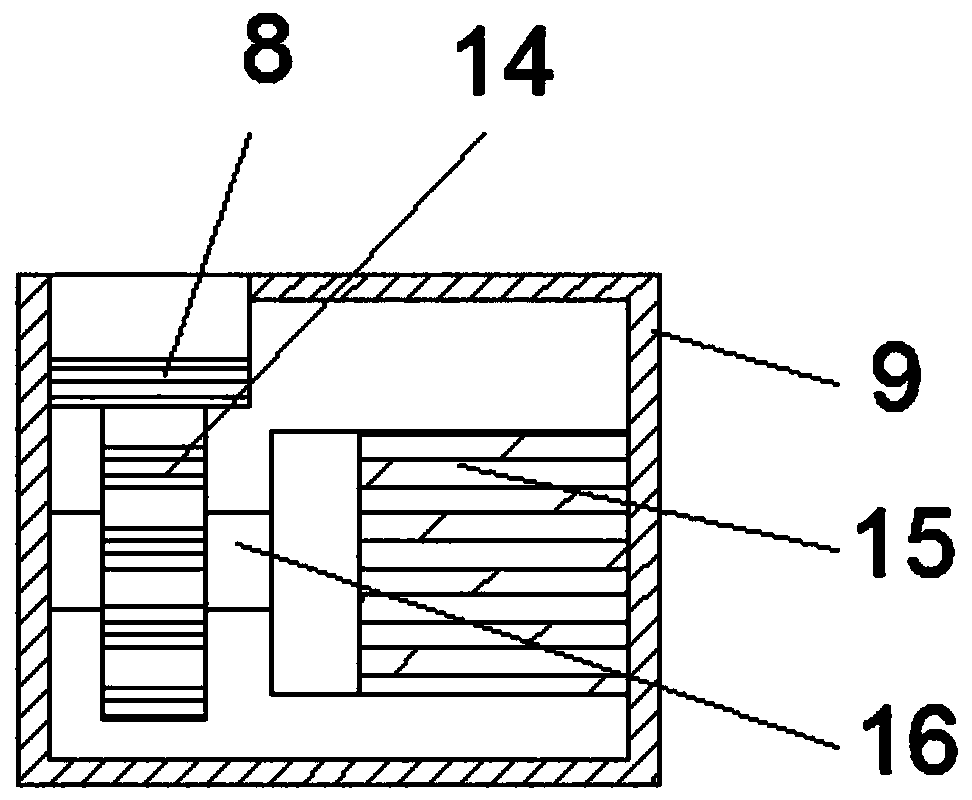

[0022] like Figure 1-Figure 4 As shown, a kind of power distribution cabinet body grinding equipment proposed by the present invention includes a flat panel 1, an equipment frame 3, a grinding device bracket 10 and a gear box 24, and the left and right sides of the lower end of the flat panel 1 are provided with universal wheels 2, and the flat panel 1 The upper end is provided with an equipment frame 3 , the top inside the equipment frame 3 is provided with a rack 8 , and the left lower part of the equipment frame 3 is provided with a dust collection device 4 , which communicates with the dust collection chamber 6 through a hose 5 ;

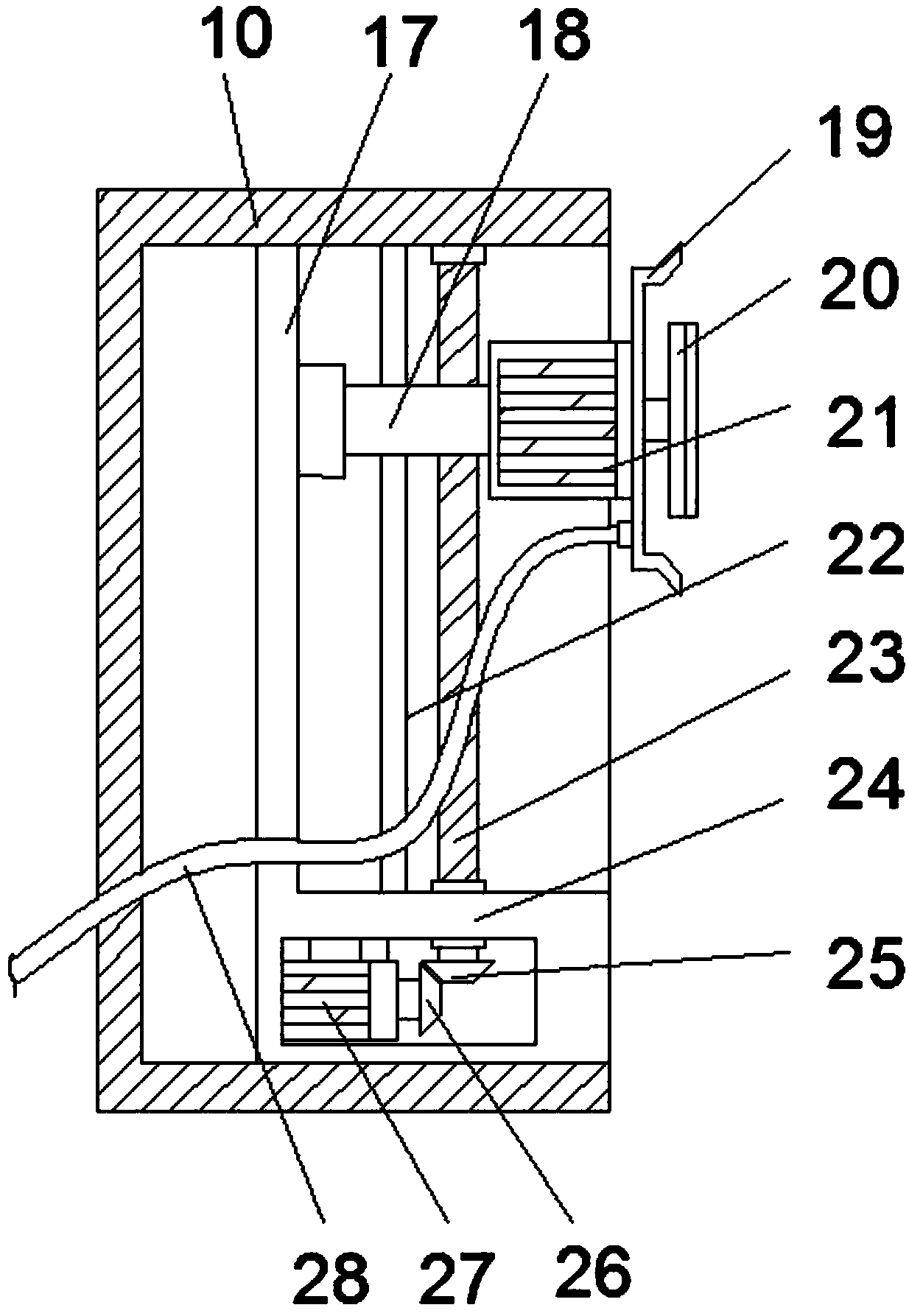

[0023] The inner bottom end of the equipment frame 3 is provided with a chute 13, and the upper end of the chute 13 is provided with a plurality of pulleys 12, the pulleys 12 are rotationally connected with the sliding bracket 11 through a rotating shaft, the upper end of the sliding bracket 11 is fixedly connected with the lower end of the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com