Efficient heat dissipation gear speed reducer

A gear reducer, high-efficiency technology, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc., can solve the problem of insufficient heat dissipation of the gear reducer, reduce the life of the gear reducer, etc., and achieve good heat dissipation effect. , Extend the service life and ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

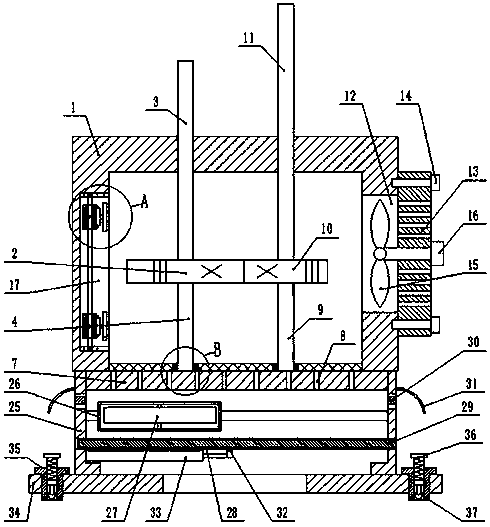

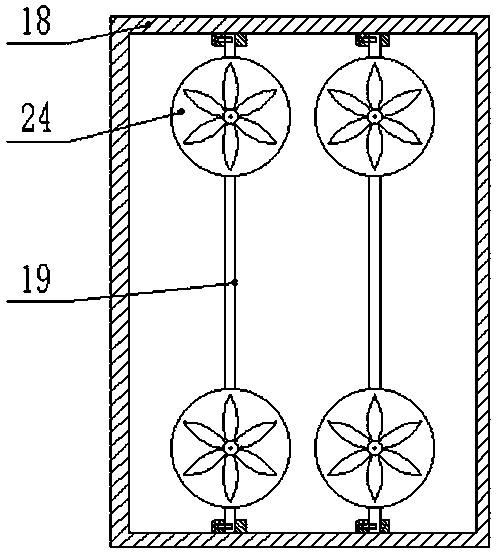

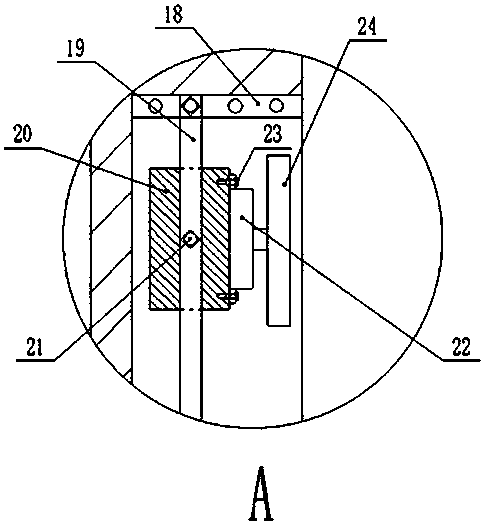

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a high-efficiency heat dissipation gear reducer includes a gear reducer body 1, and the gear reducer body 1 is provided with a large gear 2 and a pinion 10, and the large gear 2 and the pinion 10 are meshed with each other. One side of the bull gear 2 is fixedly connected to the output shaft 3, and the output shaft 3 passes through the gear reducer body 1, the other side of the bull gear 2 is fixedly connected to the connecting shaft A4, and one side of the pinion 10 is fixedly connected to the input shaft 11 , the input shaft 11 passes through the gear reducer body 1, and the other side of the pinion 10 is fixedly connected with the connecting shaft B9, and the connecting shaft A4 and the connecting shaft B9 are rotatably connected with the filter screen 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com