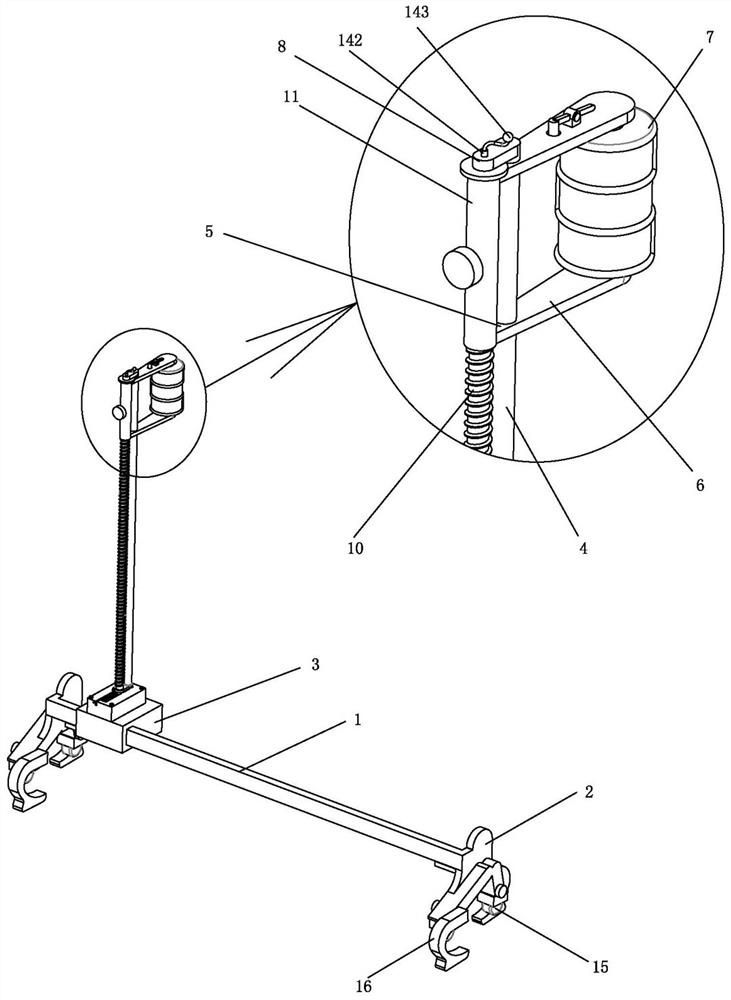

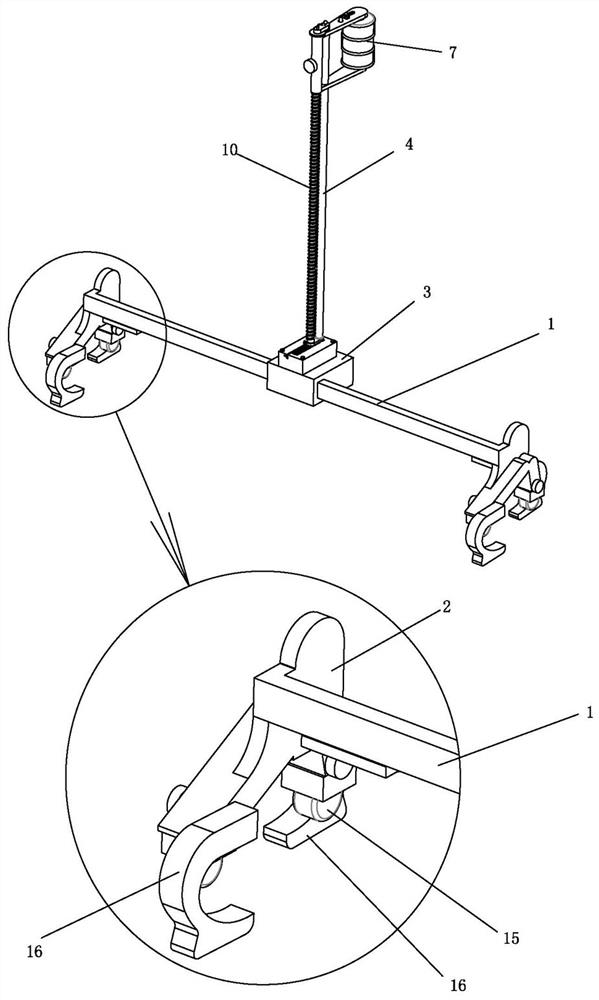

Construction equipment and building construction method

A technology of construction equipment and vertical poles, which is applied in the direction of construction and building construction, etc., can solve the problems of inability to meet customer customization, short service life of wallpaper and wall covering, and inability to guarantee the quality of wall printing, etc., to achieve rich colors, Improve printing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

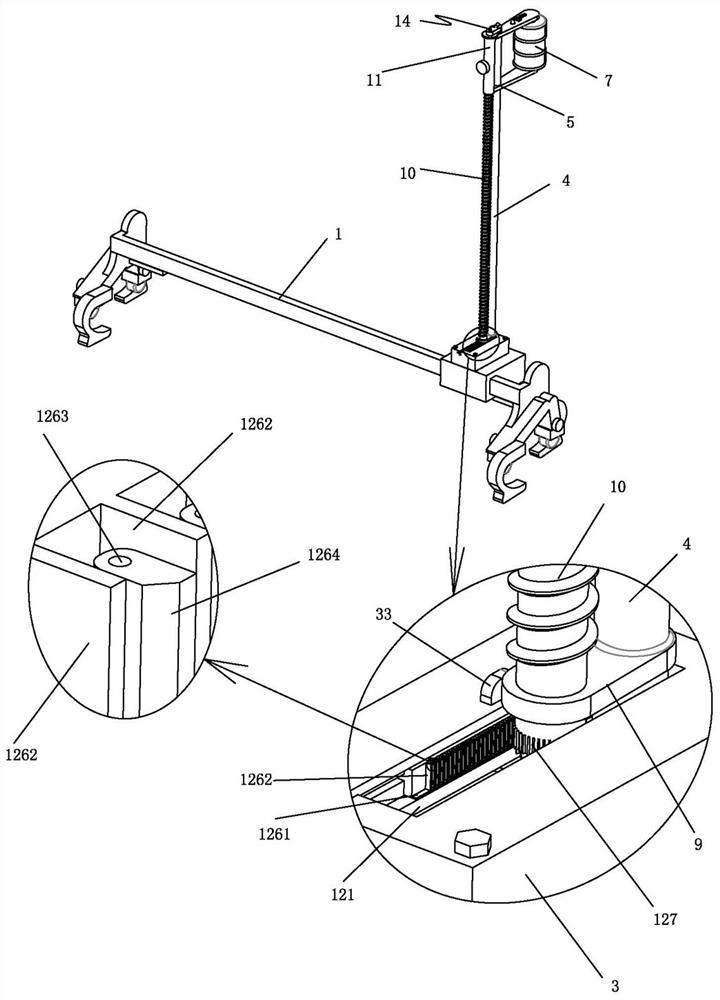

Embodiment approach

[0039] The second embodiment of the rotary drive mechanism 12 of the present invention, the rotary drive mechanism 12 of the present invention includes a relief groove 121 provided on the sliding seat 3, and the relief groove 121 extends from the front side of the sliding seat 3 to the sliding seat 3. On the rear side, the lower end of the guide vertical bar 4 is set in the relief groove 121, and a long guide groove 122 communicating with the relief groove 121 is provided in the sliding seat 3, and a There is a guide seat 123, and the guide blocks 137 arranged on both sides of the guide seat 123 are respectively arranged in the long guide groove 122, and a first return spring 125 is arranged between the guide block 137 and the rear side of the long guide groove 122. A rack is provided on one side of the relief groove 121 along the length direction, the lower end of the guide vertical bar 4 passes through the lower connecting seat 9, and a one-way gear 128 is provided at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com