Knitted Fabric For Hook-and-loop Fastener

A knitted fabric and warp knitted fabric technology, which is applied in the directions of weft knitting, warp knitting, fasteners, etc., can solve the problems of increasing thread volume and cost, and achieve the effect of increasing strength and strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

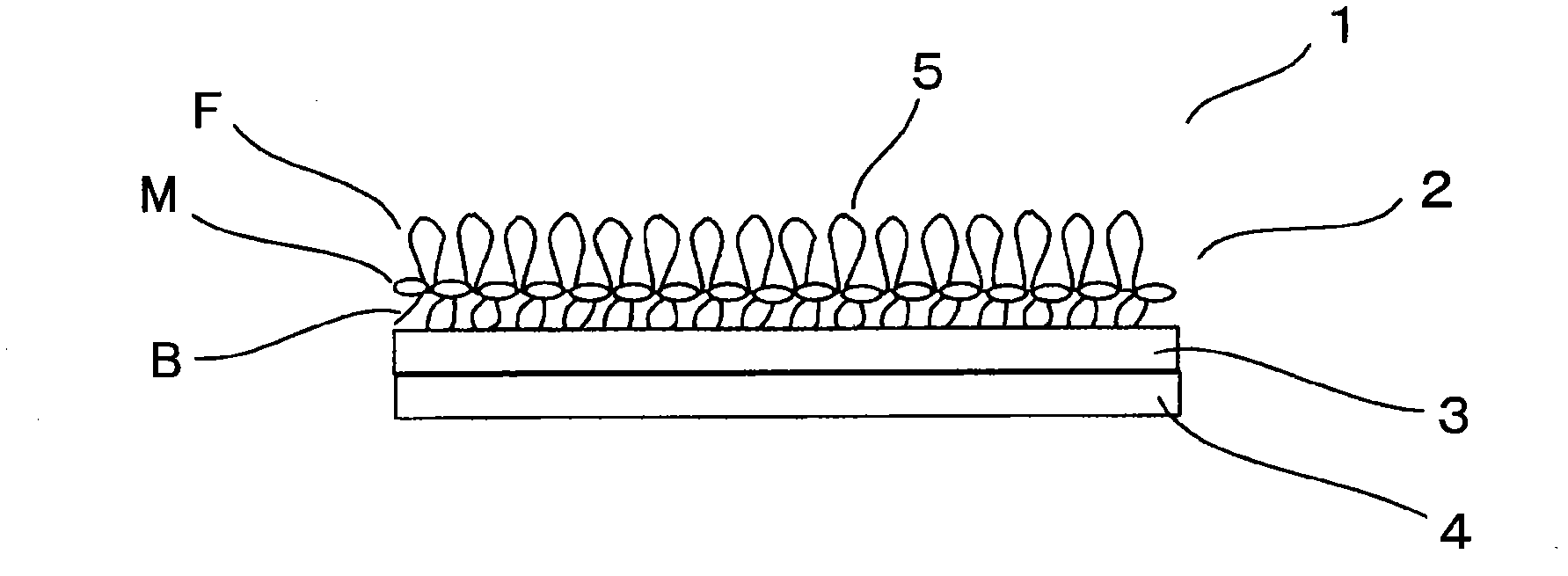

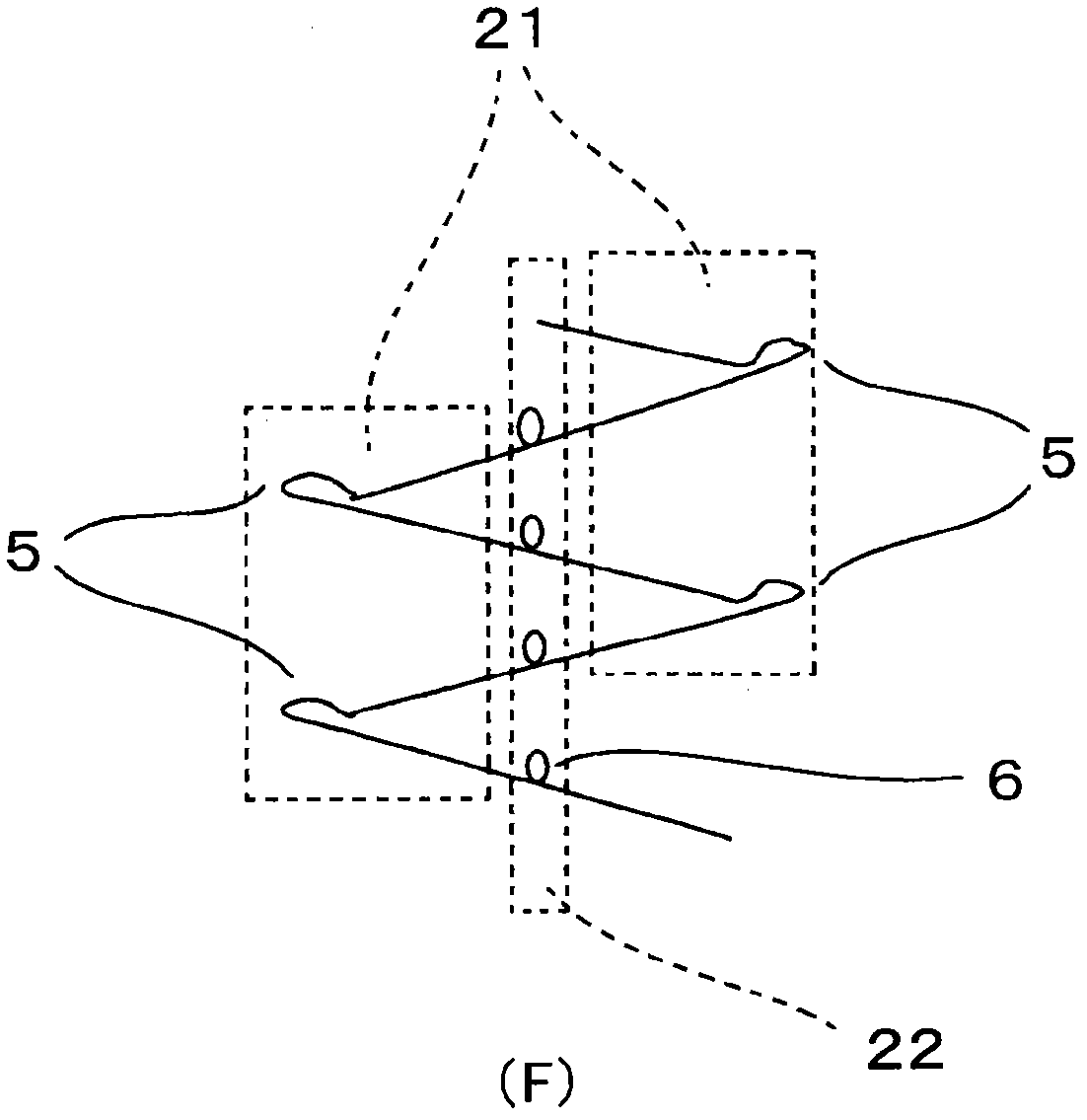

[0048] Below, refer to Figure 1 ~ Figure 3 , Figure 5 to Figure 9 Preferred embodiments of the knitted fabric for surface fasteners of the present invention will be described. In addition, in Figure 6 and Figure 7 In , the knitting yarn of the surface part (F) is shown by a dotted line, the knitting yarn of a middle part (M) is shown by a solid line, and the knitting yarn of a back part (B) is shown by a dotted line.

[0049] Such as figure 1 As shown, the suede surface (1) for surface fasteners of the present invention is mainly formed by a tricot warp knitted fabric (2), an adhesive layer (3), and a base tape (4), and the tricot warp knitted fabric is composed of a surface part ( The braided wire of F), the braided wire of the middle part (M), and the braided wire of the back part (B) are formed.

[0050] The knitting yarn of the back part (B) is connected with the adjacent knitting yarn, thereby forming a base fabric. In addition, the back part is bonded to the ad...

Embodiment 2

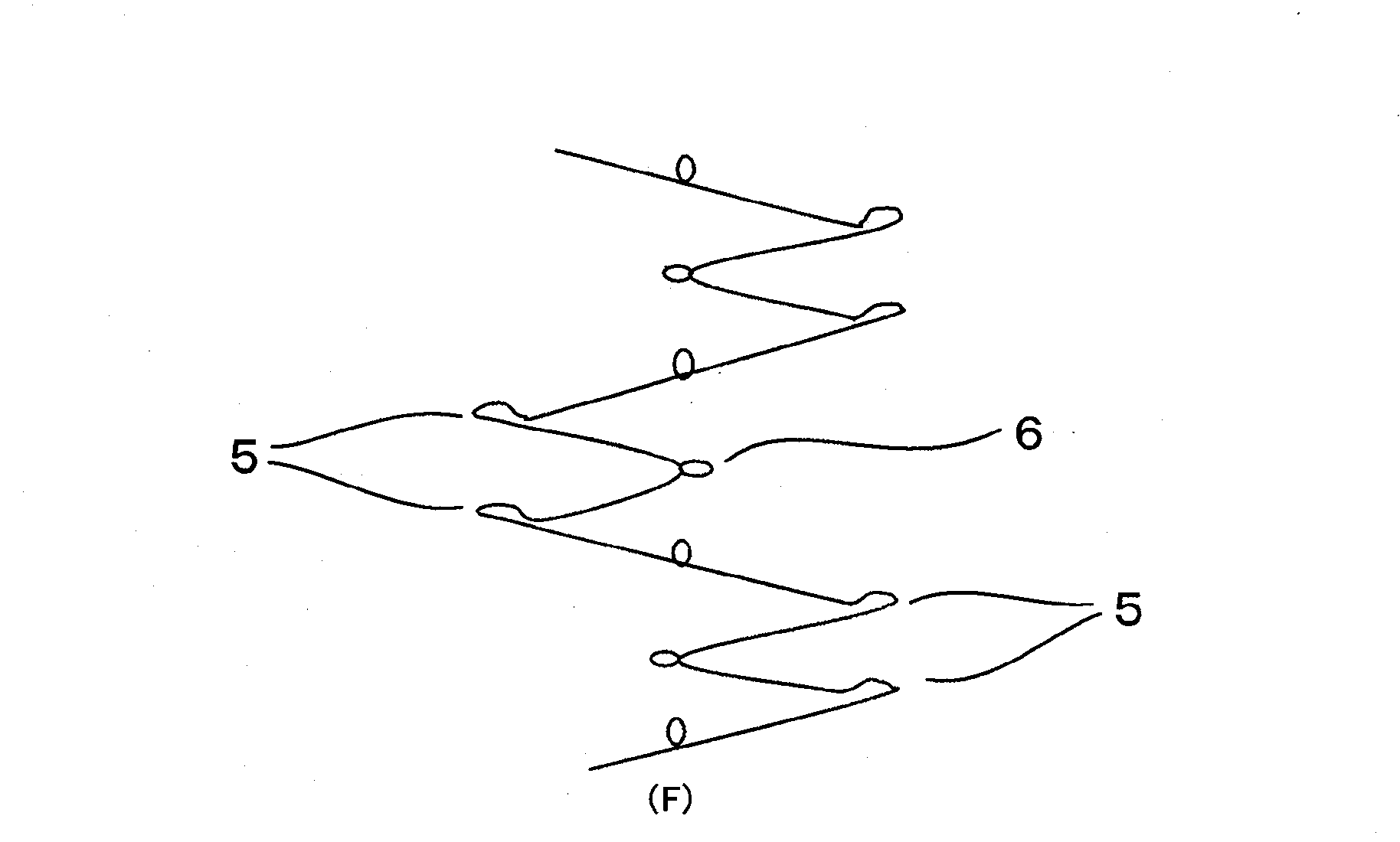

[0104] refer to Figure 4 Another example of the knitted fabric for surface fasteners of the present invention will be described. The tricot fabric of this embodiment is the same as the above-mentioned embodiment except that the stitch pattern of the knitting yarn of the surface portion (F) is different.

[0105] When the stitch pattern of the knitting thread forming the surface part (F) of the tricot warp knitted fabric of the present embodiment is represented by a cycle of stitch positions from 1 to 9, it is expressed as 4-5 / 0-1 / 4- The cycle of 5 / 0-1 / 5-4 / 9-8 / 5-4 / 9-8 indicates the stitch pattern of the surface part, such as Figure 4 Weave as shown.

[0106] That is, in the case where the continuous loop portion (6) is set as an intermediate position, every two piles (5) are alternately knitted. Thereby, two fluffs are formed on the right side, then two fluffs are formed on the left side, and then two fluffs are formed on the right side so that they are repeatedly arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com