Process of using polyurethane tackifier to improve prepressing strength of formaldehyde-free artificial board

A tackifier, polyurethane technology, applied in the direction of manufacturing tools, wood processing appliances, applications, etc., can solve the problems of inability to form, affect the production line capacity, and low efficiency, so as to improve efficiency, improve gelatinization effect, and increase adhesive performance Effect

Inactive Publication Date: 2018-12-28

李杰

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, in the process of making slabs, it is basically impossible to form, and can only rely on the support of the liner to prevent loosening and loss of shape, so that the pressing process can only use intermittent pressing methods. The intermittent pressing method is inefficient and affects the production capacity of the production line. Usually, the same scale The production line is only one-third of the capacity of the conventional urea-formaldehyde glue production line, or even less

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

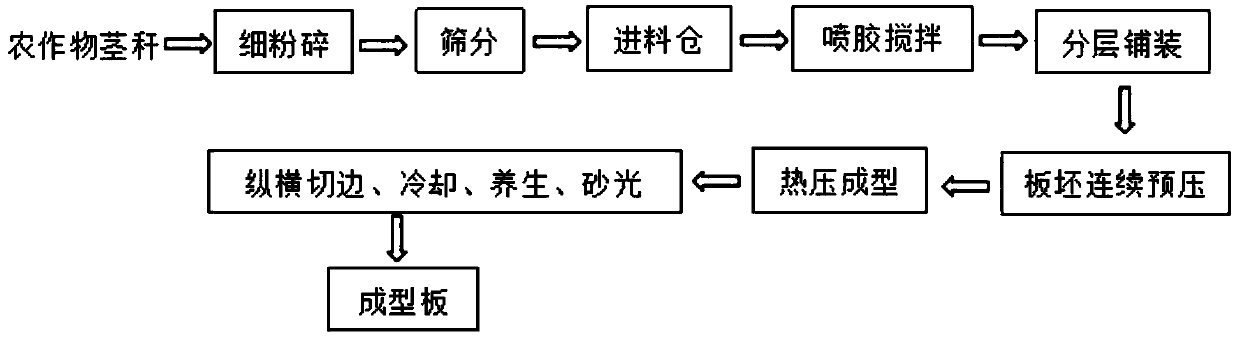

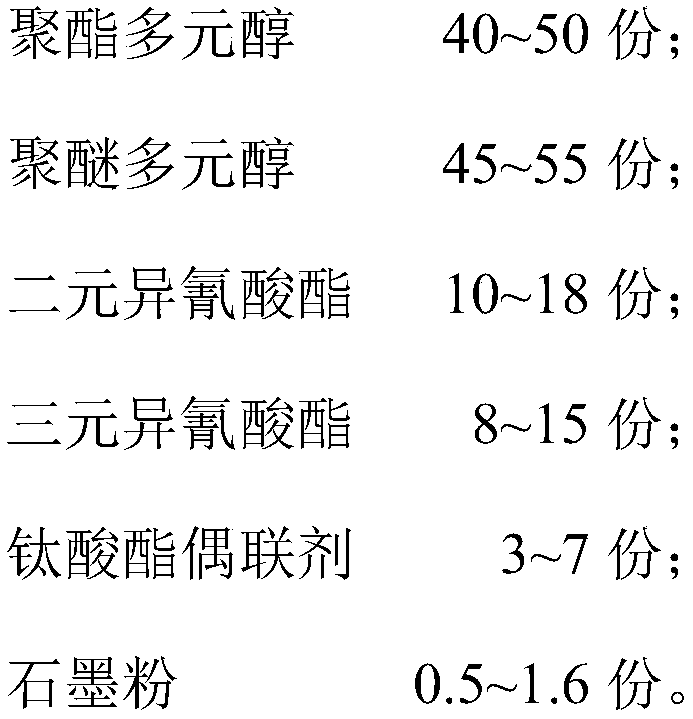

The invention provides a process of using a polyurethane tackifier to improve prepressing strength of a formaldehyde-free artificial board. The process includes following steps: step 1, smashing cropstalk to be 20-50 meshes in fineness, adding polymerization MDI glue accounting for 2-8% of weight of the crop stalk and the polyurethane tackifier accounting for 1-5% of the weight of the crop stalk,stirring and mixing, and paving to form a board blank; step 2, adopting a continuous prepress to press-roll the board blank at pressure of 250-500kN / m2; step 3, feeding the board blank into a hot press for hot-press curing at hot pressing temperature of 150-220 DEG C and at pressure of 2400-3800kN / m2 to form a rough board, and performing aftertreatment on the rough board to obtain the artificialboard.

Description

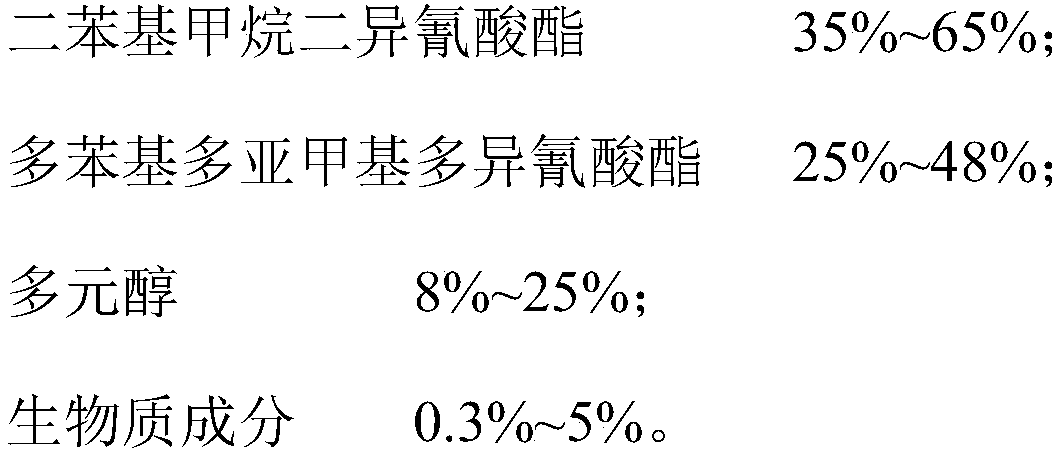

technical field The invention relates to the technical field of wood-based panels, in particular to a process for increasing the pre-compression strength of formaldehyde-free wood-based panels by using a polyurethane tackifier. Background technique The current reduction of formaldehyde emission from wood-based panels is the development trend of the wood-based panel industry. More and more manufacturers are researching and using the process of adding diphenylmethane diisocyanate (MDI) to produce wood-based panels to increase the strength of wood-based panels. The water expansion rate is reduced, so that it has a certain fireproof performance, and its formaldehyde emission is greatly reduced. However, since MDI itself is not viscous at room temperature, the cross-chain reaction occurs only under specific temperature and pressure conditions and is irreversible. Therefore, in the process of making slabs, it is basically impossible to form, and can only rely on the support of th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27N1/02B27N3/14B27N3/18

CPCB27N1/0209B27N3/14B27N3/18

Inventor 李杰

Owner 李杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com