A kind of high-content carbon fiber reinforced nylon composite material and preparation method thereof

A technology of nylon composite materials and composite materials, which is applied in the field of high-content carbon fiber reinforced nylon composite materials and its preparation, and carbon fiber reinforced nylon composite materials, which can solve the problems of poor bonding and low carbon fiber content, so as to improve mechanical properties and improve mechanical properties , good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

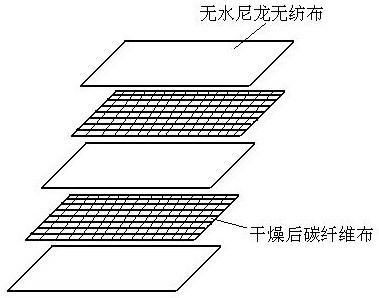

[0034] see figure 1 , a kind of preparation method of high-content carbon fiber reinforced nylon composite material, described preparation method comprises the following steps:

[0035] The first step: remove the moisture in the nylon non-woven fabric to obtain anhydrous nylon non-woven fabric, and at the same time, remove the surface impurities of the carbon fiber cloth to obtain an impurity-free carbon fiber cloth;

[0036] The second step: first impregnate the impurity-free carbon fiber cloth in the alcohol-soluble nylon absolute ethanol solution to obtain the impregnated carbon fiber cloth, then take out the impregnated carbon fiber cloth, and dry to remove the water to obtain the dried carbon fiber cloth;

[0037] The third step: first select several pieces of the above-mentioned dried carbon fiber cloth and several pieces of anhydrous nylon non-woven fabric. The quality of the dried carbon fiber cloth accounts for 65%-80% of the sum of the dried carbon fiber cloth and an...

Embodiment 1

[0058] A method for preparing a high-content carbon fiber reinforced nylon composite material, comprising the following steps:

[0059] The first step: remove the moisture in the nylon non-woven fabric to obtain anhydrous nylon non-woven fabric, and at the same time, remove the surface impurities of the carbon fiber cloth to obtain an impurity-free carbon fiber cloth;

[0060] The second step: first impregnate the impurity-free carbon fiber cloth in the alcohol-soluble nylon anhydrous ethanol solution to obtain the impregnated carbon fiber cloth, then take out the impregnated carbon fiber cloth, and dry to remove the water to obtain the dried carbon fiber cloth; preferably alcohol-soluble The mass percent concentration of the nylon absolute ethanol solution is 0.5%-3%; the impurity-free carbon fiber cloth is preferably immersed in the alcohol-soluble nylon absolute ethanol solution for 8-16 hours;

[0061] The third step: first select several pieces of the above-mentioned drie...

Embodiment 2

[0064] Basic content is the same as embodiment 1, the difference is:

[0065] The hot press forming includes a hot press stage, a first cooling stage, and a second cooling stage carried out in sequence;

[0066] The hot-pressing stage refers to: hot-pressing the laminated body in the mold from the upper and lower directions;

[0067] The first cooling stage refers to: cooling the laminate under pressure in the mold;

[0068] The second cooling stage refers to: cooling the laminate in the mold;

[0069] The cooling rate of the second cooling stage is greater than that of the first cooling stage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com