Technology for increasing pre-pressing strength of formaldehyde-free artificial board by using hot melt adhesive

A technology of hot-melt adhesives and wood-based panels, which is applied in the direction of manufacturing tools, wood processing appliances, applications, etc., can solve problems that affect production line production capacity, take a long time, and cannot be formed, so as to improve gelatinization effect, increase efficiency, and increase production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

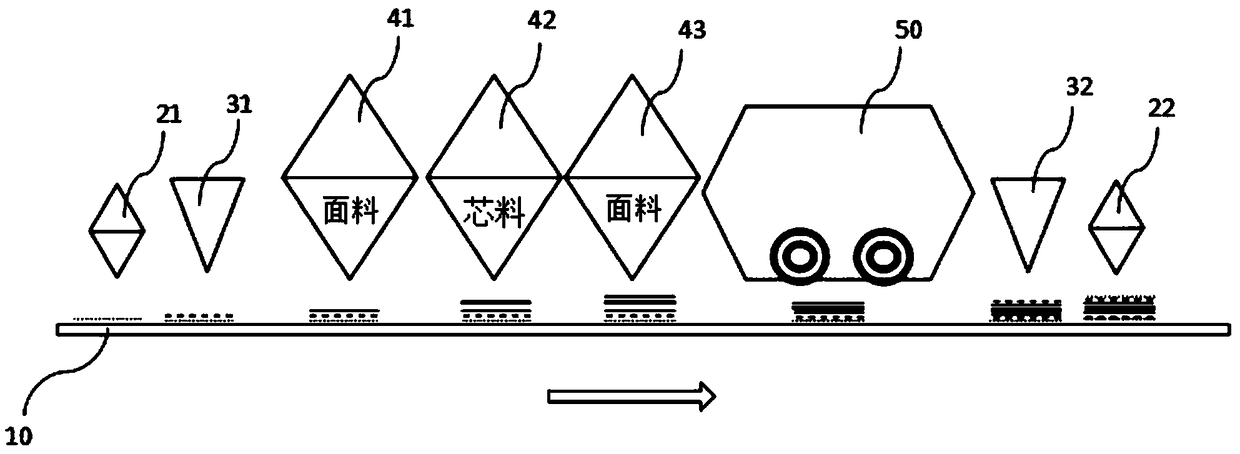

Method used

Image

Examples

Embodiment 1

[0028] In step one, crop stalks containing 80% kenaf stalks are used as raw materials, and then the crop stalks are compressed and packaged for storage. Coarsely crushed crop stalks are dried by a tumble dryer so that the moisture content is within the range of 9% to 17%.

[0029] The dried crop stalks are then passed through wind selection and other equipment to remove impurities such as iron and stones, and then enter the fine grinder to be crushed to a fineness of 10-60 mesh and sieved. After sieving, the crop stalks with a fineness of 10-30 mesh The stalks are sent to the core layer silo, and the 30-60 mesh crop stalks are sent to the surface layer silo.

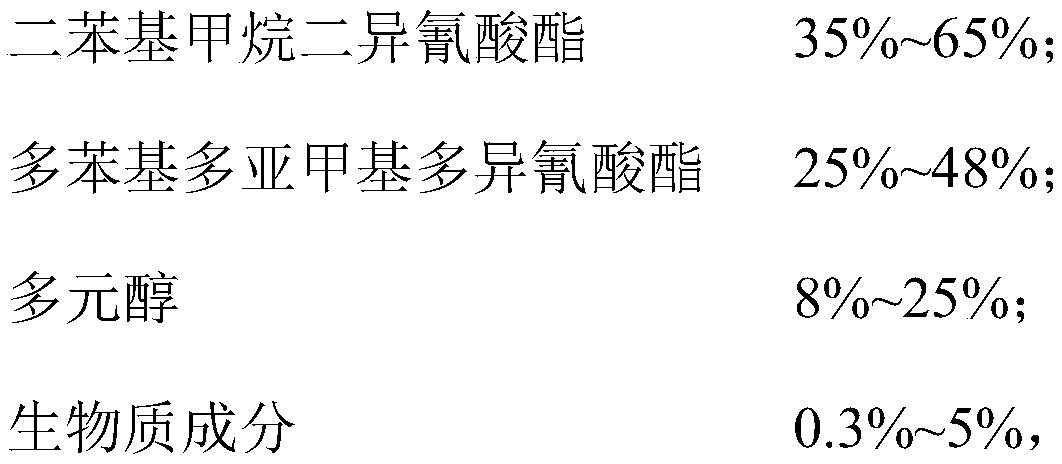

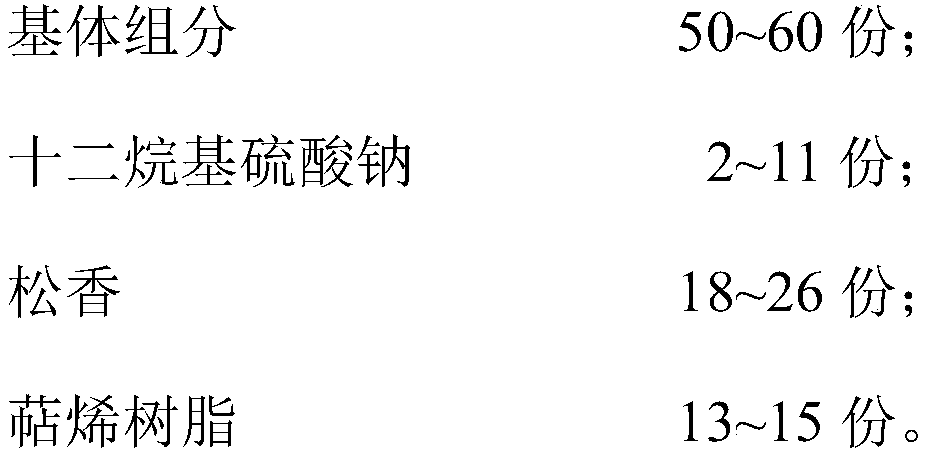

[0030] The crop stalks in the core layer silo and the surface layer silo are weighed separately, and their moisture content is measured by a moisture tester, and sent to different mixers respectively, and the glue spraying device is controlled by PLC to spray glue, according to Corresponding weight controls the amount o...

Embodiment 2

[0041] In step one, jute stalks are used as raw materials, and then the jute stalks are compressed and packaged for storage. Coarsely crushed jute stalks are dried by a tumble dryer so that their moisture content is within the range of 9% to 17%.

[0042] The dried jute stalks are then passed through wind selection and other equipment to remove impurities such as iron and stones, and then enter the fine grinder to be crushed to a fineness of 10-60 mesh and sieved. After sieving, the jute stalks with a fineness of 10-30 mesh The stalks are sent to the core layer silo, and the 30-60 mesh jute stalks are sent to the surface layer silo.

[0043] The jute stalks in the core layer silo and the surface layer silo are weighed respectively, and their moisture content is measured by a moisture tester, and sent to different mixers respectively, and the glue spraying device is controlled by PLC to spray glue, according to Corresponding weight controls the amount of glue spraying, and the...

Embodiment 3

[0054] In the first step, hemp crop stalks mixed with kenaf stalks and jute stalks are used as raw materials, and then the hemp crop stalks are compressed and packaged for storage. The coarsely crushed hemp crop stalks are dried by a tumble dryer so that the moisture content is within the range of 9% to 17%.

[0055] The dried hemp crop stalks are then passed through wind selection and other equipment to remove impurities such as iron and stones, and then enter the fine grinder to be crushed to a fineness of 10-60 mesh and sieved. After sieving, the hemp with a fineness of 10-30 mesh The crop stalks are sent to the core layer silo, and the 30-60 mesh hemp crop stalks are sent to the surface layer silo.

[0056] The hemp crop stalks in the core silo and the surface silo are weighed separately, and the moisture content is measured by a moisture tester, and sent to different mixers, and the glue spraying device is controlled by PLC to spray glue. According to the corresponding w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com