Non-woven fabric board for exterior of vehicle and method for manufacturing same

A non-woven and object-board technology, which is applied to vehicle parts, textiles, papermaking, non-woven fabrics, etc., can solve the problems of strength degradation, component weight and material cost increase, and low bulkiness of cloth fabrics, etc., to improve thermoformability , Improve the bonding efficiency, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

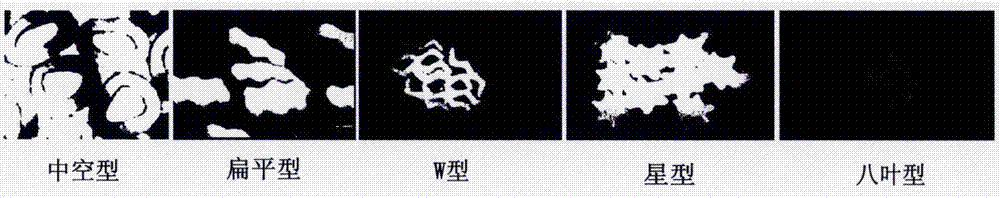

[0077] PET fibers as non-circular cross-section matrix fibers and non-circular cross-section binder fibers including low-melting PET fibers were used in a weight ratio of 6:4, and non-circular cross-section binder fibers were produced using conventional production processes for thermally bonded non-woven fabrics. Fabric board. The nonwoven fabric sheet is formed to have a thickness of 2 mm and an areal density of 1,200 g / m 2 .

[0078] As the non-circular cross-section matrix fiber and non-circular cross-section binder fiber as described above, fibers having a W-shaped cross-section produced by melt spinning with a W-shaped spinneret were used, and a crimp number of 9.8 was used. ea / inch, a fiber with a non-circularity of 2.6 and a linear density of 7 denier.

Embodiment 2

[0080] PET fibers as non-circular cross-section matrix fibers and non-circular cross-section binder fibers including low-melting PET fibers were used in a weight ratio of 6:4, and non-circular cross-section binder fibers were produced using conventional production processes for thermally bonded non-woven fabrics. Fabric board. The nonwoven fabric sheet is formed to have a thickness of 2 mm and an areal density of 1,200 g / m 2 .

[0081] As the non-circular cross-section matrix fiber and non-circular cross-section binder fiber as described above, fibers having a W-shaped cross-section produced by melt spinning with a W-shaped spinneret were used, and a crimp number of 9.8 was used. ea / inch, fibers with a non-circularity of 2.6, and fibers with a linear density of 14 denier were used as non-circular cross-section matrix fibers, and fibers with a linear density of 7 denier were used as non-circular cross-section binder fibers.

Embodiment 3

[0083] PET fibers as non-circular cross-section matrix fibers and non-circular cross-section binder fibers including low-melting PET fibers were used in a weight ratio of 6:4, and non-circular cross-section binder fibers were produced using conventional production processes for thermally bonded non-woven fabrics. Fabric board. The nonwoven fabric sheet is formed to have a thickness of 2 mm and an areal density of 1,200 g / m 2 .

[0084] As the non-circular cross-section matrix fiber and non-circular cross-section binder fiber as described above, fibers having a W-shaped cross-section produced by melt spinning with a W-shaped spinneret were used, and a crimp number of 9.8 was used. ea / inch, fibers with a non-circularity of 2.0, and as non-circular cross-section matrix fibers, fibers with a linear density of 14 denier were used as non-circular cross-section matrix fibers, and fibers with a linear density of 7 denier were used as Non-circular cross-section bonded fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| perimeter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com