A kind of environment-friendly brass alloy with excellent formability and its manufacturing method

A brass alloy and forming performance technology, applied in the field of alloys, can solve problems such as cutting processing difficulties, poor welding performance and thermoforming performance, and reduce alloy fluidity, so as to improve thermoforming performance and casting performance, and improve cutting performance and thermoforming performance, and the effect of improving molding and casting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

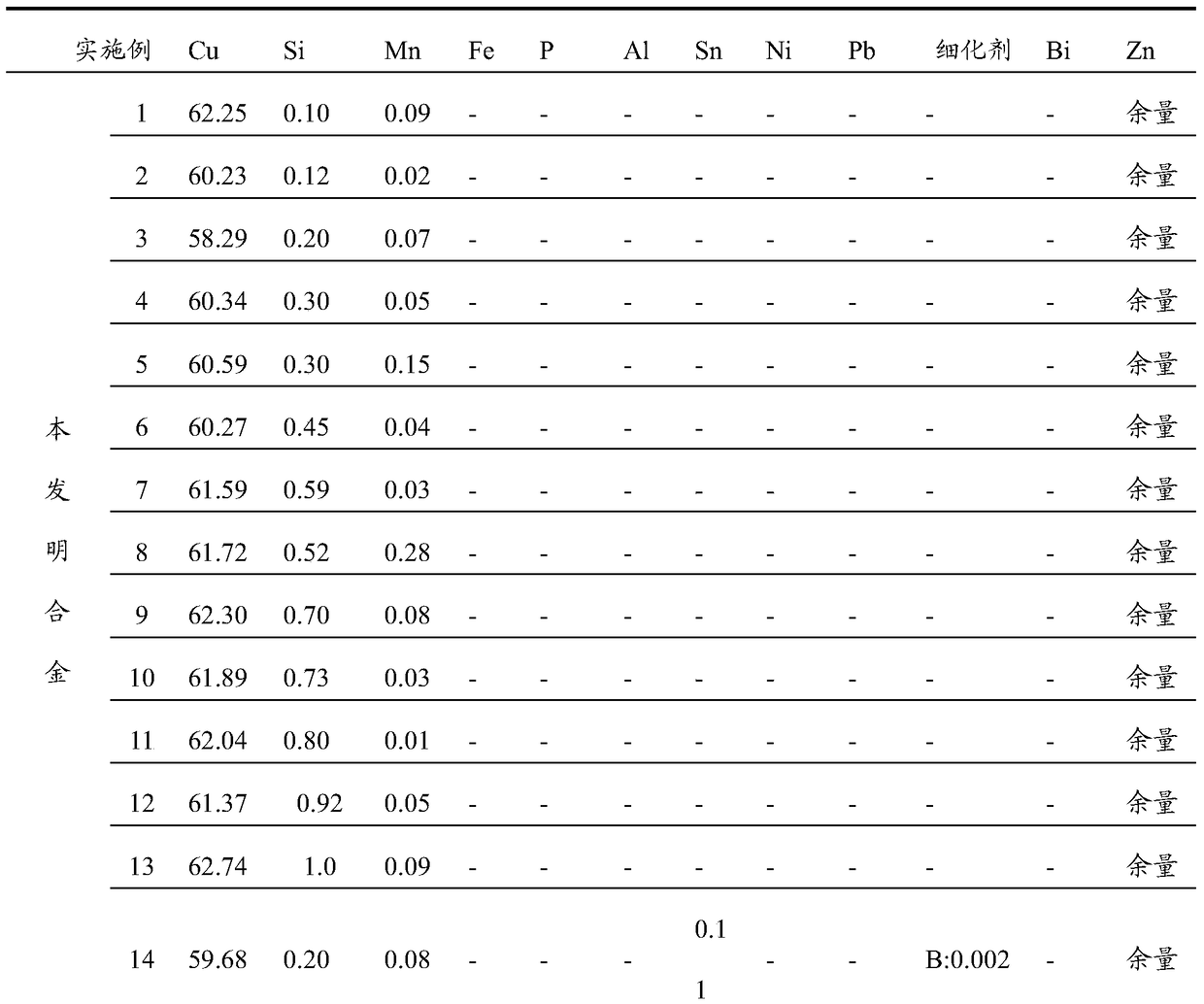

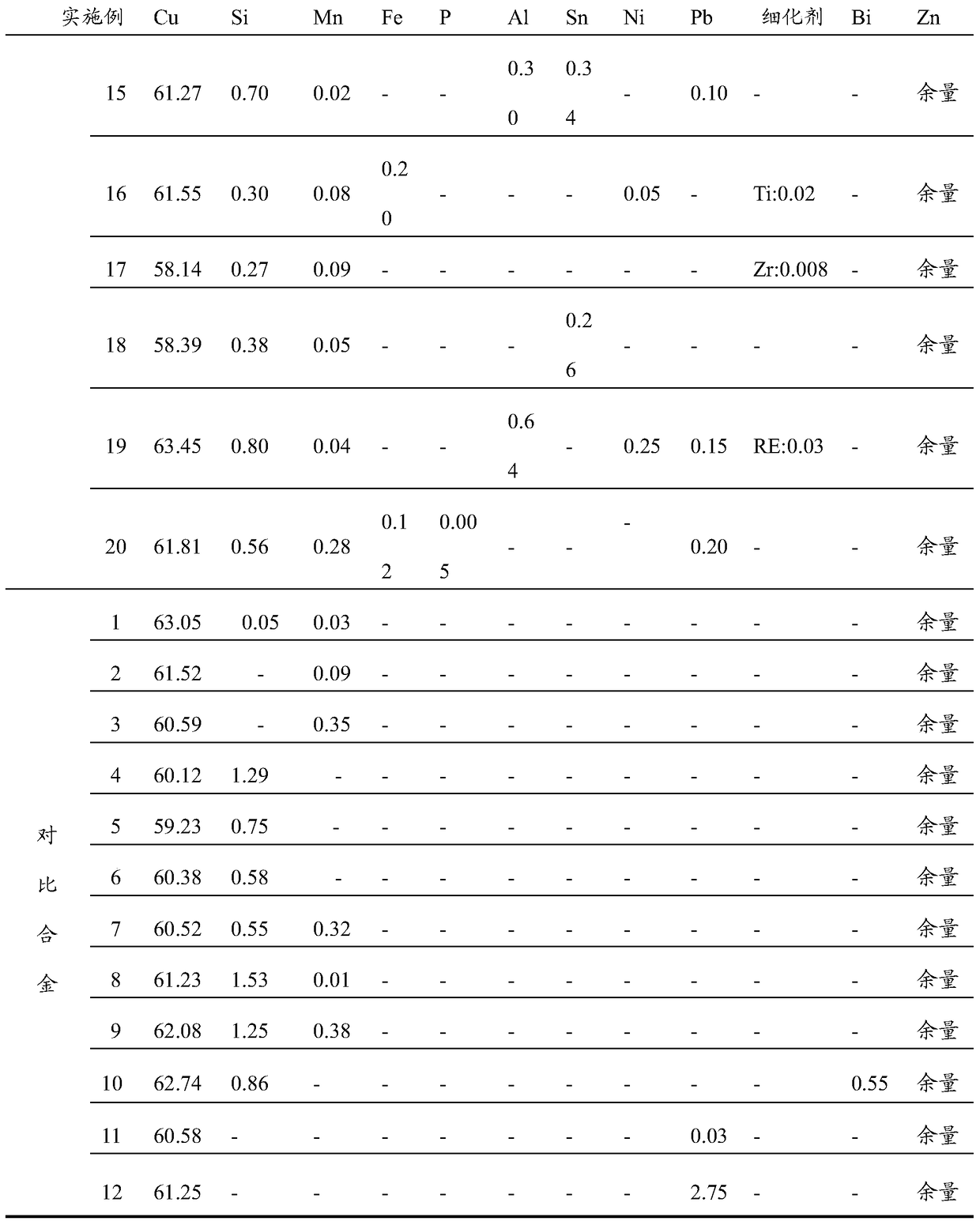

[0036] The composition of the alloy of the present invention and the comparison alloy is shown in Table 1, wherein the comparison alloy 10 is brass containing bismuth silicon, the comparison alloy 11 is simple brass CuZn40, and the comparison alloy 12 is C36000 alloy.

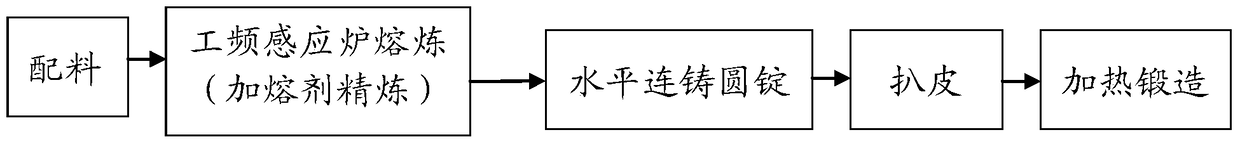

[0037] The alloy of the present invention and the comparison alloy are all according to figure 1 The process shown is smelted and cast into round billets with the same specifications. The specific preparation process is: batching, smelting, horizontal continuous casting, peeling and heating forging, wherein the temperature of the horizontal continuous casting is 990-1060°C, and the temperature of the heating forging is 680-760°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com