Superplastic forming nanocrystalline antibacterial martensitic stainless steel and preparation method thereof

A martensitic stainless steel and nanocrystalline technology, applied in the field of materials, can solve the problems of reduced thermal processing performance of materials, increase of thermal processing costs of materials, small size of prepared materials, etc., to achieve improved thermal forming performance, best comprehensive mechanical properties, excellent The effect of antimicrobial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

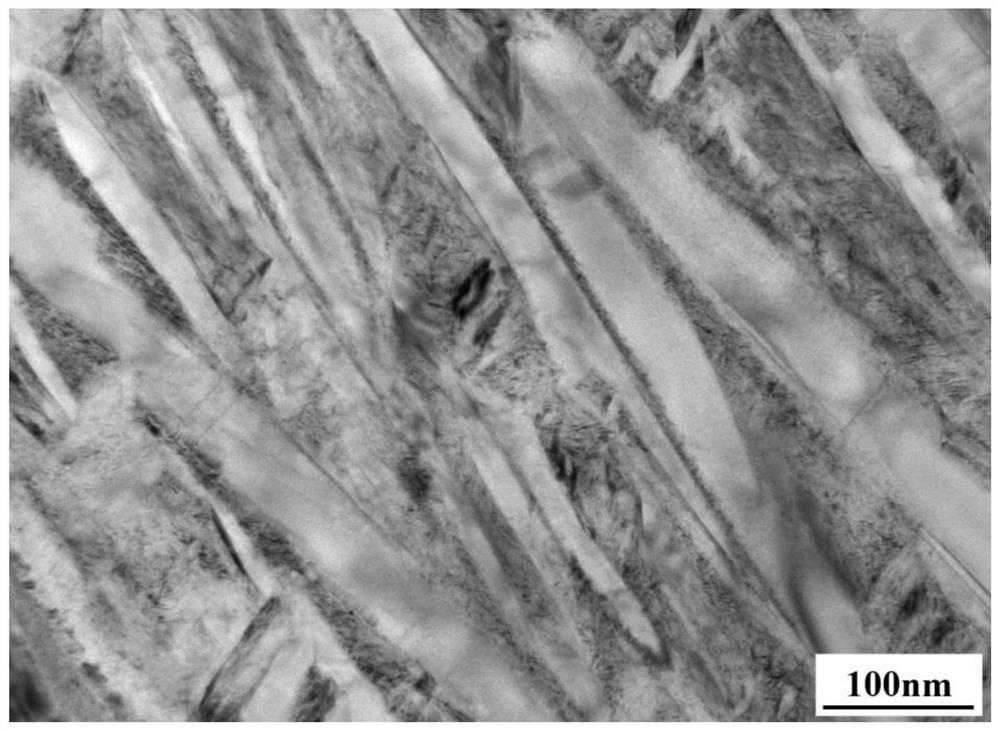

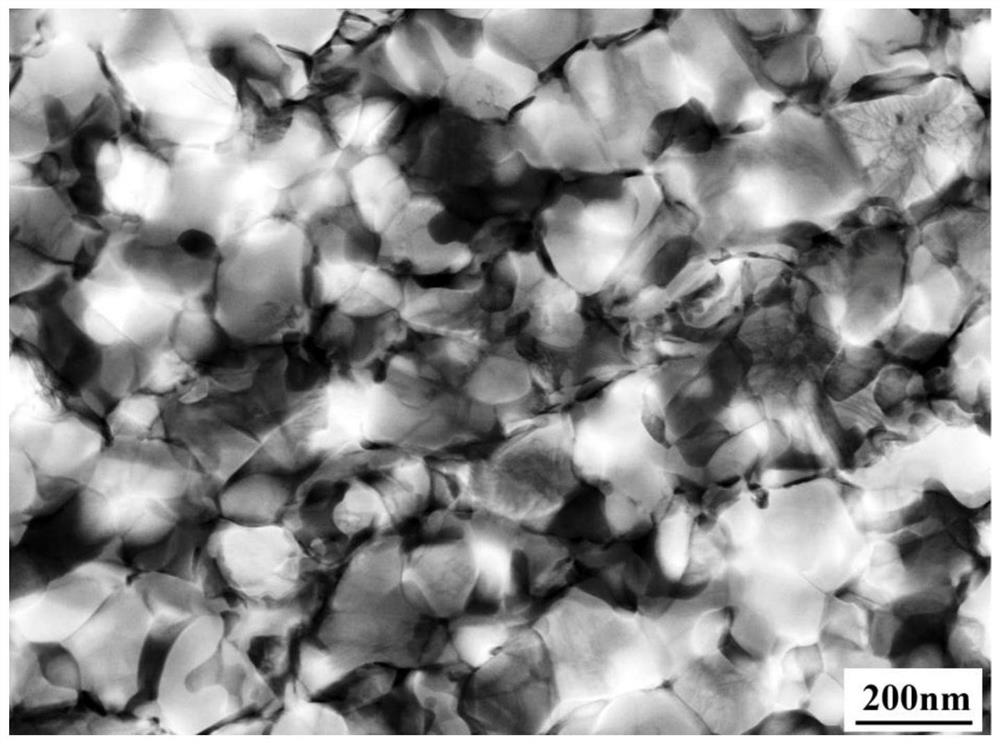

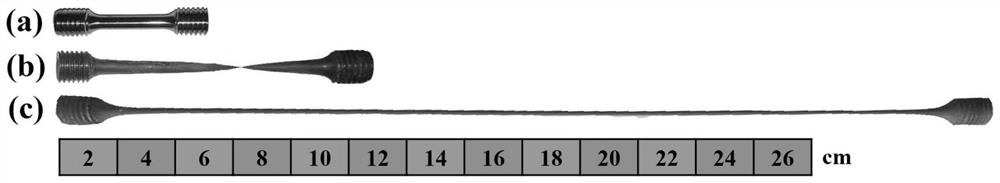

[0030] Embodiment: Examples 1 to 9 are stainless steels smelted according to the chemical composition range provided by the present invention, and the content of C, Cr, Cu, W, V elements is gradually increased, and the corresponding preparation process is also specified in the technical parameters of the present invention Make appropriate adjustments within the range. The size of the prepared bulk nanocrystalline metal material is 150×800×8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pitting potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com