Aluminum alloy with high conductivity uniformity and preparation method and application thereof

An aluminum alloy, uniformity technology, applied in the field of aluminum alloy, can solve the problem that the uniformity of aluminum alloy conductivity cannot be well controlled, and achieve the effect of ensuring dimensional stability, uniform structure, and fine grains of cast ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

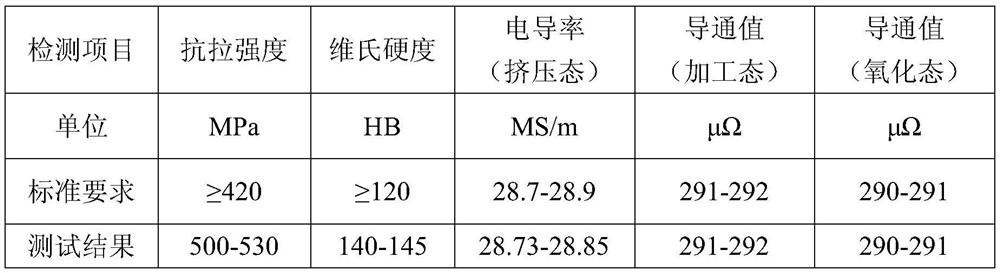

Embodiment 1

[0040] An aluminum alloy with high electrical conductivity uniformity, the composition and content of which are:

[0041] Si: 0.4189wt%, Fe: 0.2588wt%, Cu: 4.6711wt%, Mn: 0.7218wt%, Mg: 1.6551wt%, Cr: 0.0511wt%, Zn: 0.1536wt%, Ni: 0.0121wt%, Ti: 0.05112wt%, Sn: 0.0052wt%, Sb: 0.03576wt%, Pb: 0.01184wt%, Bi: 0.0009wt%, Ga: 0.00985wt%, V: 0.01389wt%, Zr: 0.00247wt%, C: 0.0011wt% %, B: 0.00219wt%, single impurity ≤ 0.05wt%, alloy impurity ≤ 0.12wt%, the balance is Al;

[0042] The preparation method comprises the following steps:

[0043] (1) Casting: Select 1120-purity aluminum ingots and smelt aluminum water equivalent to 1120-purity, control the temperature of the smelting aluminum liquid at 750°C-900°C, and add silicon, iron, copper, and manganese when the temperature of the aluminum liquid reaches 800°C , magnesium, chromium, tin, antimony, bismuth, and zirconium elements continue to heat up and melt, and at the same time turn on the electromagnetic stirring device until a...

Embodiment 2

[0051] An aluminum alloy with high electrical conductivity uniformity, the composition and content of which are:

[0052] Si: 0.4356wt%, Fe: 0.3156wt%, Cu: 4.7112wt%, Mn: 0.7655wt%, Mg: 1.732wt%, Cr: 0.0651wt%, Zn: 0.1754wt%, Ni: 0.01313wt%, Ti: 0.07512wt%, Sn: 0.0072wt%, Sb: 0.03482wt%, Pb: 0.01192wt%, Bi: 0.00092wt%, Ga: 0.0095wt%, V: 0.01375wt%, Zr: 0.00241wt%, C: 0.0031wt% %, B: 0.00195wt%, single impurity ≤ 0.05wt%, alloy impurity ≤ 0.12wt%, the balance is Al;

[0053] The preparation method comprises the following steps:

[0054] (1) Casting: Select 1120-purity aluminum ingots and smelt aluminum water equivalent to 1120-purity, control the temperature of the smelting aluminum liquid at 830-950°C, and add silicon, iron, copper, manganese, Magnesium, chromium, tin, antimony, bismuth, and zirconium elements continue to heat up and melt, and at the same time turn on the electromagnetic stirring device until all the added elements are melted, then add 2024 alloy cold materi...

Embodiment 3

[0062] An aluminum alloy with high electrical conductivity uniformity, the composition and content of which are:

[0063] Si: 0.4611wt%, Fe: 0.356wt%, Cu: 4.871wt%, Mn: 0.8421wt%, Mg: 1.7881wt%, Cr: 0.0811wt%, Zn: 0.2001wt%, Ni: 0.0121wt%, Ti: 0.152wt%, Sn: 0.00932wt%, Sb: 0.03532wt%, Pb: 0.01182wt%, Bi: 0.0009wt%, Ga: 0.00983wt%, V: 0.01382wt%, Zr: 0.0241wt%, C: 0.0015wt% %, B: 0.00208wt%, single impurity ≤ 0.05wt%, alloy impurity ≤ 0.12wt%, the balance is Al;

[0064] The preparation method comprises the following steps:

[0065] (1) Casting: Select 1120-purity aluminum ingots and smelt aluminum water equivalent to 1120-purity, control the temperature of the smelting aluminum liquid at 800-950°C, and add silicon, iron, copper, manganese, Magnesium, chromium, tin, antimony, bismuth, and zirconium elements continue to heat up and melt, and at the same time turn on the electromagnetic stirring device until all the added elements are melted, then add 2024 alloy cold material t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com