Oriented fluoropolymer film

A technology of oriented film and copolymer, which is applied in the field of oriented fluoropolymer film, can solve the problems such as the reduction of MIT flex life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0084] Unless otherwise specified, the compositions used in the following examples were dry / extruded blends of FEP and PFA having the following composition (all % based on total weight of copolymer):

[0085] PFA: Copolymer of TFE and 7.5% by weight PEVE with an MFR of 7 g / 10 minutes, a melting temperature of 290°C, and an elongation of 290%.

[0086] FEP 1: Copolymer of TFE, 10% by weight HFP and 1.2% by weight PEVE, the copolymer has 6 About 20 unstable end groups (mainly -COOH) per carbon atom, MFR of 20 g / 10 min, melting temperature of 255° C. and elongation of 361%.

[0087] FEP 2: Copolymer of TFE, 10% by weight HFP and 1.2% by weight PEVE, the copolymer has 6 About 25 unstable end groups per carbon atom (mainly -COOH), MFR of 30 g / 10 min, melting temperature of 257° C. and elongation of 345%.

[0088] 15 sec at a melt temperature of 350 °C and a draw ratio characterized by a speed much greater than the film line speed of the extrusion speed -1 A dry blend of FEP and ...

example 1

[0094] Example 1 - Improved Hinge Durability

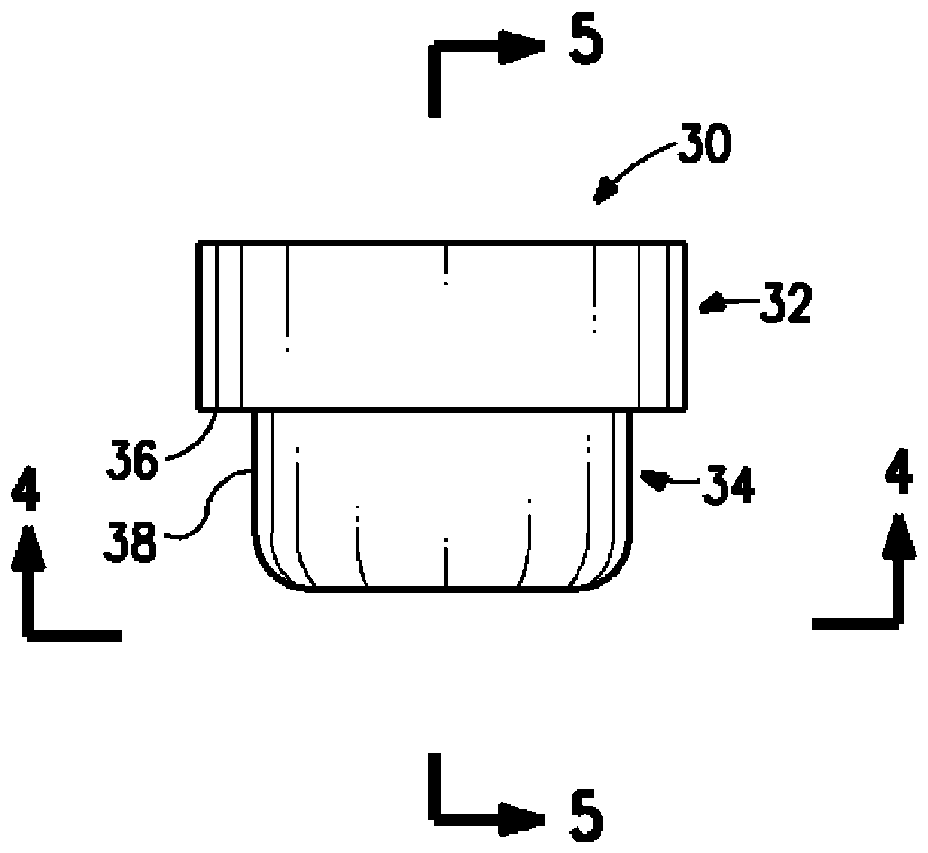

[0095] Two oriented 5.5 mil (0.14 mm) thick films are heat sealed to form a container such as figure 1 with figure 2 shown. The films were each Composition 1. Heat sealing was accomplished by using a heat bar heated to 260° C. which pressed the overlapping film portions together against the platen for a few seconds. The presence of the heat seal was observed by the fact that the interface between the overlapping film portions was no longer visible. The width of the heat seal is 1 / 8 inch (3.2 mm). The heat seal is allowed to air cool and then repeated to form the remaining sides on the container.

[0096]The container was subjected to multiple cycles of inflation and deflation until one of the films broke at one of the heat seals, which was detected by the inability to inflate the container. Aeration is performed by filling the container with enough air to support a 6 inch (15.2 cm) column of water. Perform deflation by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com