Decorative film and method for producing decorative molded body using same

A technology for decorative films and resin moldings, which is applied in the direction of chemical instruments and methods, decorations, applications, etc., and can solve the problems of insufficient adhesive strength between decorative films and moldings, insufficient solvent resistance and heat resistance, and decorative problems. Satisfactory reproducibility, excellent water resistance and chemical resistance, and extended heating time can be achieved without problems such as film cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0943] {Example 1-1}

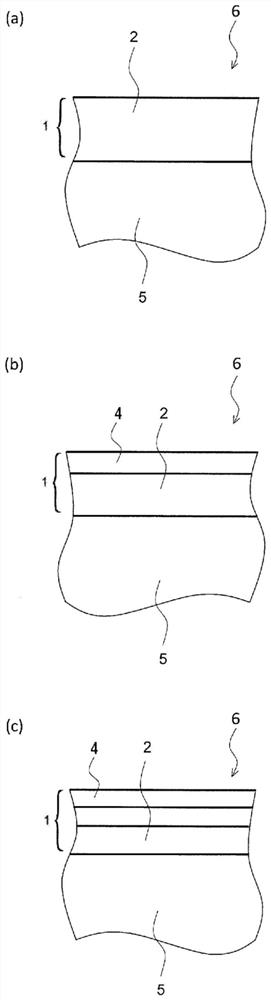

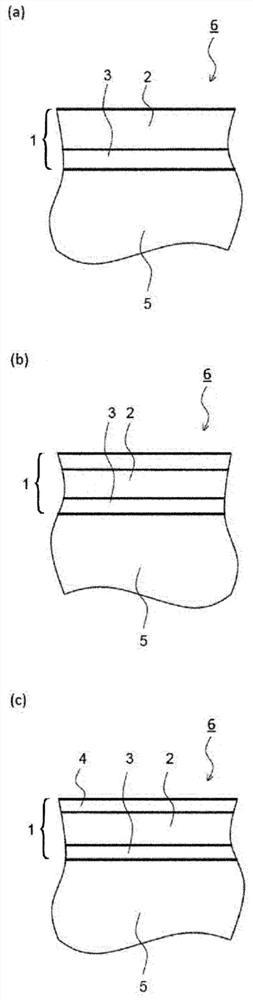

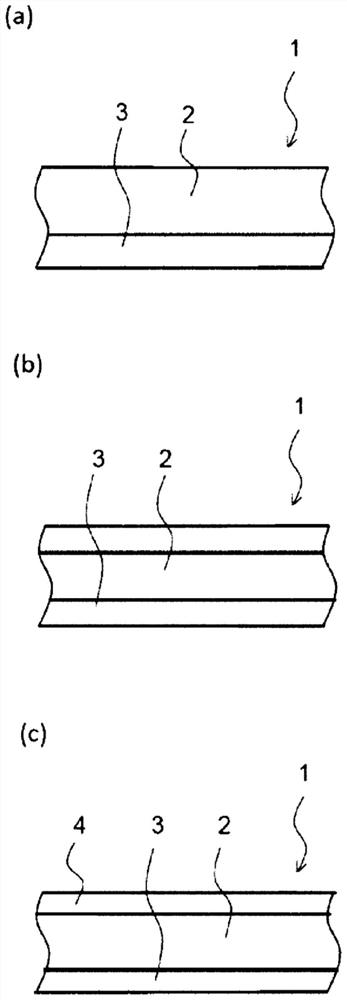

[0944] - Production of decorative films

[0945] Using an extruder with a nozzle diameter of 40 mm (diameter), the polypropylene-based resin (1A-1-1) was extruded under the conditions of a resin temperature of 240° C. and a discharge rate of 13 kg / h, and introduced into the resin that has been controlled at 240°C. Melt extrusion was performed in a single-layer T-die having a temperature of °C, a die width of 400 mm, and a die lip opening of 0.8 mm. The melt-extruded film was cooled and solidified on a roll rotating at 3 m / min at 80° C. to obtain a single-layer unstretched film with a thickness of 200 μm. The unstretched film constitutes layer (I) of the decorative film.

[0946] - 3D decorative thermoforming

[0947] As the resin molded body (substrate) 5, the injection molded body composed of the polypropylene-based resin (1X-1) obtained above was used.

[0948]As a three-dimensional decorative thermoforming apparatus, "NGF-0406-SW" manufactured by ...

Embodiment 1-2 to 1-5

[0964] {Examples 1-2 to 1-5}

[0965] Except in the three-dimensional decorative thermoforming of Example 1-1, the polypropylene-based resin (1A-1-1) was changed to the polypropylene-based resins (1A-1-1) and (1A-2-) described in Table 2 Except for each blend (resin composition (B)) of 1), molding and evaluation were performed in the same manner as in Example 1-1. Table 2 shows the obtained results.

[0966] Since the MFR of the resin composition (B) is 40 g / 10 minutes or less and the strain hardening degree l is 1.1 or more, the obtained decorative molded body is excellent in appearance and adhesive force. In addition, the appearance of the regenerated molded body is excellent.

Embodiment 1-6

[0967] {Example 1-6}

[0968] In the three-dimensional decorative thermoforming of Example 1-1, the same procedure as in Example 1-1 was carried out, except that the polypropylene-based resin (1A-1-1) was changed to the polypropylene-based resin (1A-2-1). Methods were formed and evaluated. Table 2 shows the obtained results.

[0969] Since the MFR of the polypropylene-based resin (1A-1-2) is 40 g / 10 minutes or less and the strain hardening degree λ is 1.1 or more, the obtained decorative molded body is excellent in appearance and adhesive force. In addition, the appearance of the regenerated molded body is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com