A kind of protective film that does not rebound under hot pressing and preparation method thereof

A technology of protective film and protective film layer, which is applied in the directions of heat-activated film/sheet, chemical instrument and method, film/sheet release liner, etc. Production cost and other issues, to achieve the effect of reducing overall hardness, excellent hot-pressing performance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

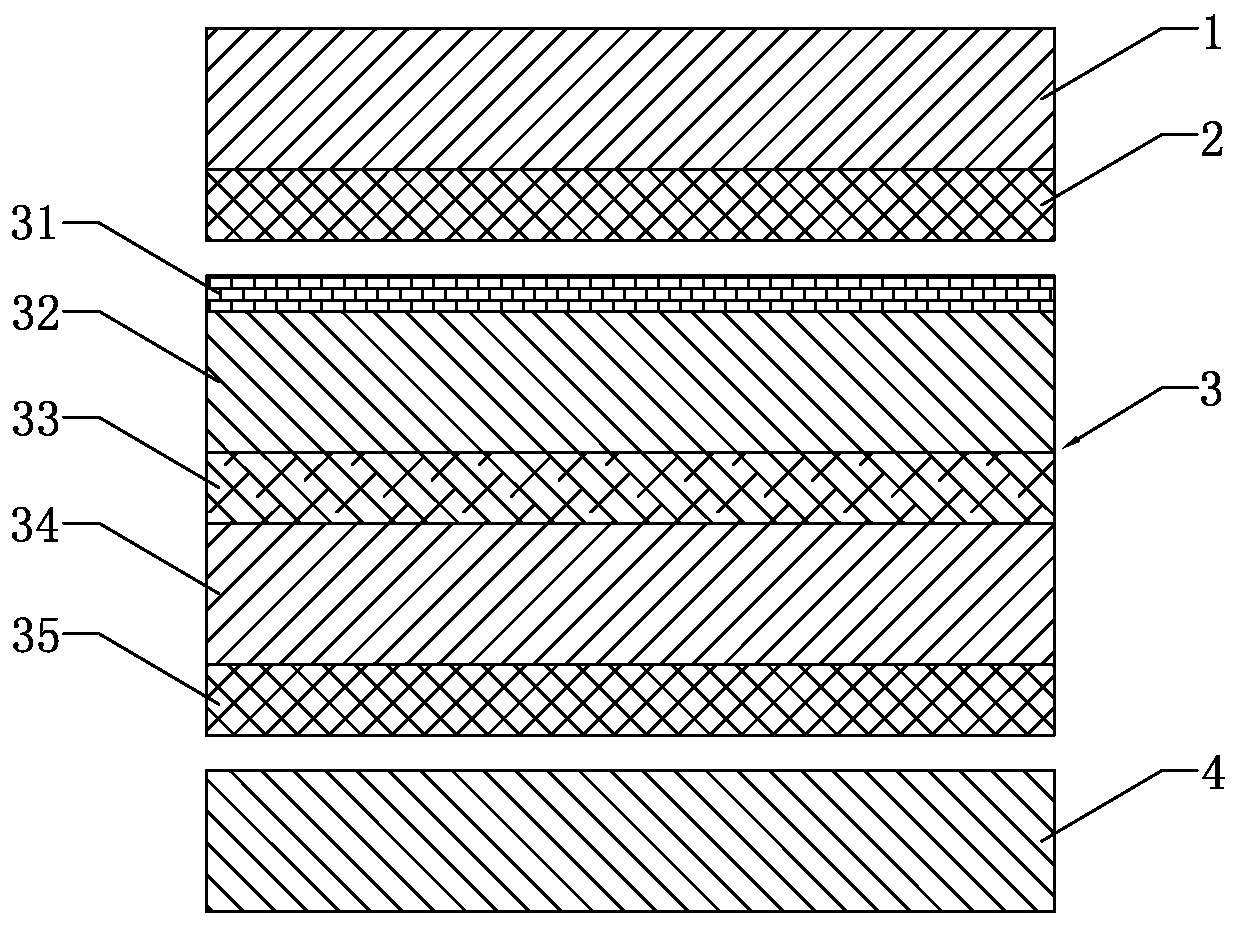

[0035] See figure 1 , a protective film that does not rebound after hot pressing, including a protective film layer 1, a protective adhesive layer 2, a use film layer 3 and a peeling film layer 4 sequentially pasted from top to bottom; the use film layer 3 includes The UV hard glue layer 31 on the lower surface of layer 2, the first UV soft glue layer 32 that is attached to the lower surface of the UV hard glue layer 31, the base material layer 33 that is attached to the lower surface of the first UV soft glue layer 32, and the bonding The second UV soft adhesive layer 34 on the lower surface of the substrate layer 33, and the peeling adhesive layer 35 attached to the lower surface of the second UV soft adhesive layer 34, the lower surface of the peeling adhesive layer 35 and the upper surface of the peeling film layer 4 fit.

[0036] The protective film layer 1, the substrate layer 33 and the peeling film layer 4 are all PET films with a light transmittance of more than 91%;...

Embodiment 2

[0049] The difference between this embodiment and the above-mentioned embodiment 1 is that: the protective film layer 1, the substrate layer 33 and the peeling film layer 4 are all PEN films with a light transmittance of more than 91%; the peeling film layer 4 It is a non-silicon-treated release film; the UV hard rubber layer 31 is a polyurethane rubber layer with a hardness of 2H; the first UV soft rubber layer 32 and the second UV soft rubber layer 34 are both hard at 0.6H Polyurethane adhesive layer.

[0050] The thickness of the protective film layer 1, the substrate layer 33 and the peeling film layer 4 is 60 μm; the thickness of the protective adhesive layer 2 is 8 μm; the thickness of the peeling adhesive layer 35 is 40 μm; the UV hard adhesive layer 31. Both the first UV soft glue layer 32 and the second UV soft glue layer 34 have a thickness of 3 μm.

[0051] The raw material of the UV hard glue layer 31 is polyurethane resin glue of model 6146-100 produced by Changx...

Embodiment 3

[0058] The difference between this embodiment and the above-mentioned embodiment 1 is that: the protective film layer 1, the substrate layer 33 and the peeling film layer 4 are all PC films with a light transmittance of more than 91%; the peeling film layer 4 It is a fluoroplastic release film; the UV hard glue layer 31 is an acrylic glue layer with a hardness of 3H; the first UV soft glue layer 32 and the second UV soft glue layer 34 are both acrylic glue layers with a hardness of 0.5H .

[0059] The thickness of the protective film layer 1, the substrate layer 33 and the peeling film layer 4 is 120 μm; the thickness of the protective adhesive layer 2 is 12 μm; the thickness of the peeling adhesive layer 35 is 60 μm; the UV hard adhesive layer 31. Both the first UV soft glue layer 32 and the second UV soft glue layer 34 have a thickness of 5 μm.

[0060] The raw materials of the protective adhesive layer 2 and the peeling adhesive layer 35 are silicone pressure-sensitive adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com