Unleaded brass alloy

A brass alloy and lead-free brass technology, applied in the field of alloys, can solve the problems of high production cost, easy hot and cold brittleness, environmental pollution, etc., to solve the problem of waste recycling, improve cutting performance, comprehensive performance excellent effect

Active Publication Date: 2016-07-20

LA VIDA IND +1

View PDF13 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Adding bismuth-silicon brass overcomes the shortcoming of poor welding performance of bismuth brass, but it is easy to produce hot and cold brittleness in the thermoforming process, and bismuth is a rare and precious metal, and the production cost is relatively high (such as Chinese patent 200610005689.2, 200310120259.1, U.S. patent US6942742B1, etc.)

Antimony-added silicon brass, because antimony itself is toxic, the antimony in the brass is very easy to dissolve during use. Its faucets, valves and other wet products have been tested by NSF. The amount of antimony element dissolved in water far exceeds the standard 0.6 μg / L, there are hidden dangers of polluting the environment and endangering human health, and cannot be applied to plumbing parts (such as Chinese patents 200410015836.5, 200710070803.4, etc.)

Zirconium-added silicon brass is rare and expensive due to the scarcity of zirconium resources, and it is extremely easy to combine with oxygen, sulfur and other oxidizing media in the alloy melting process and convert into slag and lose its effect. Poor recyclability (such as Chinese patent 200810143070)

Due to the addition of titanium in silicon brass, the polishing performance of the alloy is poor, so it is not suitable for appearance parts

The addition of phosphorus in silicon brass leads to poor forging performance of the alloy and easy overburning (such as Chinese patents 200910042723.7, 200810180201.9, etc.)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

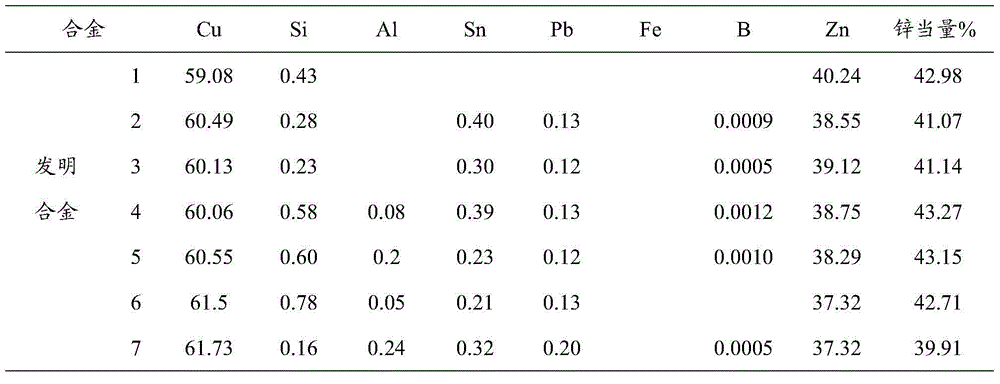

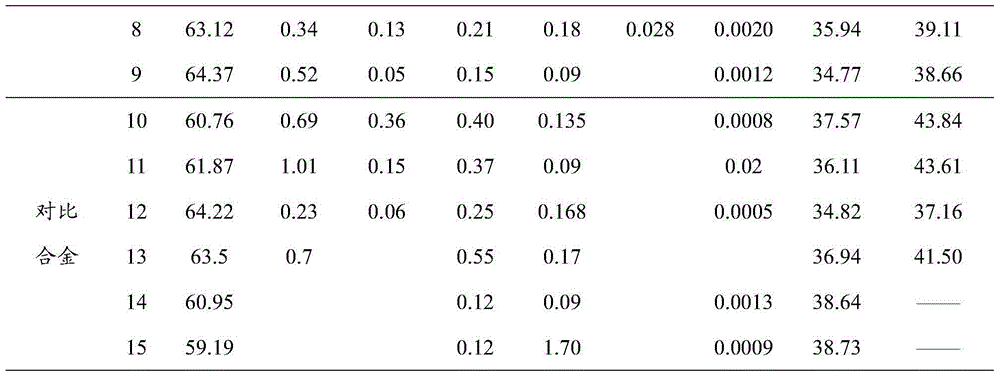

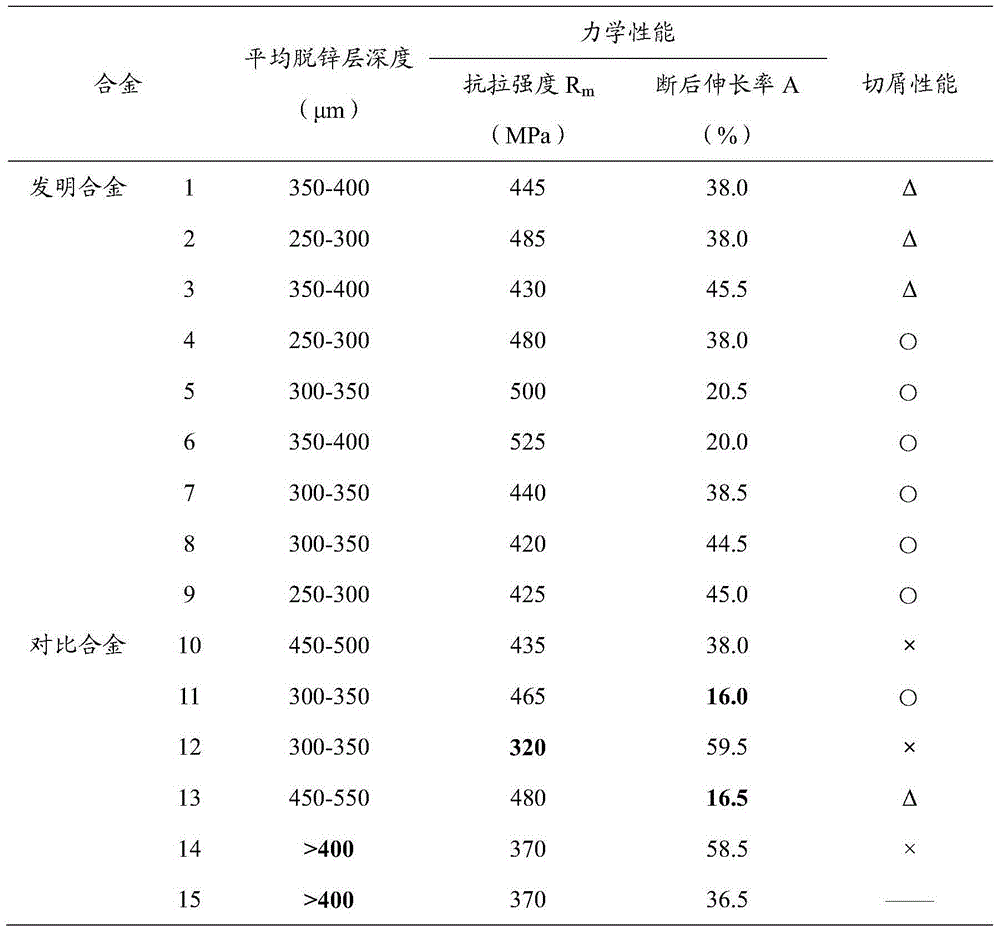

[0036] The composition of the alloy of the present invention and the comparison alloy is as shown in Table 1, wherein the specific embodiment of the invention alloy is 1~9, and the comparison alloy is 10~15, wherein the comparison alloy 14 is the composition of simple brass CuZn40, and the comparison alloy 15 is leaded Composition of brass CuZn40Pb2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides unleaded brass alloy. The unleaded brass alloy contains 59.0%-65.0% wt% of Cu, 0.1%-1.0% wt% of Si, and the balance Zn and unavoidable impurities, and the Zn equivalent X of the unleaded brass alloy is within the range of 38%-43.5%. The following formula X=(Znwt%+10.0xSiwt%+2.0xSnwt%+6.0xAlwt%) / (Cuwt%+Znwt%+10.0xSiwt%+2.0xSnwt%+6.0xAlwt %) represents the Zn equivalent X. The unleaded brass alloy has good formability and polishing performance, and is suitable for parts, of bathroom plumbing, electric products, automobiles and the like, formed by casting and forging, in particular for water faucets and other products with complex structures.

Description

technical field [0001] The invention belongs to the technical field of alloys, in particular to a lead-free brass alloy. Background technique [0002] Traditional lead brass has been used as an important basic material in electrical, mechanical, plumbing and other fields due to its excellent cutting performance, low production cost, and good processing performance. However, because lead is extremely harmful to the human body and can damage the human bone marrow hematopoietic system and nervous system, its pollution hazard has attracted great attention. Developed economies such as the United States, the European Union, and Japan have legislated to impose strict restrictions on lead content in drinking water systems, plumbing fittings, toys, household appliances, etc., such as NSF-ANSI372, AB-1953, RoHS, etc., which are gradually banned Manufacture, sell and use products containing lead. [0003] At present, a lot of research work has been done on the lead-free brass at home...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C9/04

Inventor 许传凯胡振青毕秋龙佳吕青张卫星张华威

Owner LA VIDA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com