An alloy with good hot formability, corrosion resistance, fatigue properties, toughness and weldability

A technology of fatigue performance and welding performance, applied in the field of aluminum alloy, can solve the problem of no alloy, and achieve the effect of increasing hot formability, uniform structure and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

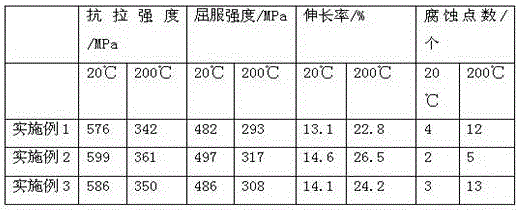

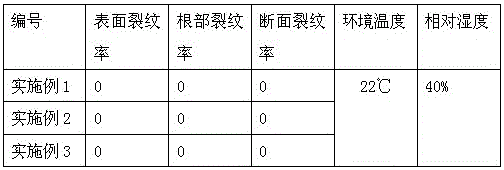

Examples

preparation example Construction

[0018] A method for preparing an alloy with good thermal formability, corrosion resistance, fatigue performance, toughness and weldability, comprising the following steps: alloy ingot casting, extrusion quenching, tension stretching and aging treatment, sampling inspection, and packaging.

[0019] Alloy ingots include smelting and refining. The melting temperature is 700-830°C. Stir steadily when the furnace charge is about 90% melted. It is forbidden to involve surface scum into the molten metal; each furnace is melted 2-5 times during the melting process. Stirring at the bottom of the furnace; take samples immediately after the body is evenly stirred, and carry out pre-furnace analysis. 10 minutes, casting and molding.

[0020] The technical parameters of extrusion quenching are: the ingot is heated to 300-320°C and quickly loaded into the extrusion cylinder, the extrusion temperature is 320°C-330±5°C, the extrusion speed is 3±0.5m / min, and the quenching temperature is 360- ...

Embodiment 1

[0024] An alloy with good thermoformability, corrosion resistance, fatigue performance, toughness and weldability, the alloy is composed of the following components: Mg0.62wt%, Mn0.10wt%, Cr0.12wt%, Si0.72wt% %, Fe 0.010wt%, Cu 0.04 wt%, Zn <0.1 wt%, Ti 0.02 wt%, V0.08 wt%, the balance is Al and unavoidable impurities

Embodiment 2

[0026] An alloy with good thermoformability, corrosion resistance, fatigue performance, toughness and weldability, the alloy is composed of the following components: Mg0.63wt%, Mn0.16wt%, Cr0.15wt%, Si0.73wt% %, Fe 0.02 wt%, Cu 0.05 wt%, Zn <0.1 wt%, Ti 0.03 wt%, V0.09 wt%, the balance is Al and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com