PE vacuum aluminized composite film and preparation method thereof

A technology of vacuum aluminum plating and composite film, which is applied in the field of packaging materials to prevent the aluminum plating film from falling off, realize large-scale production, and improve thermoforming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

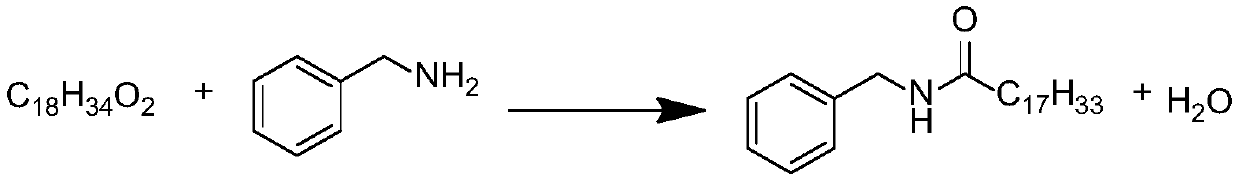

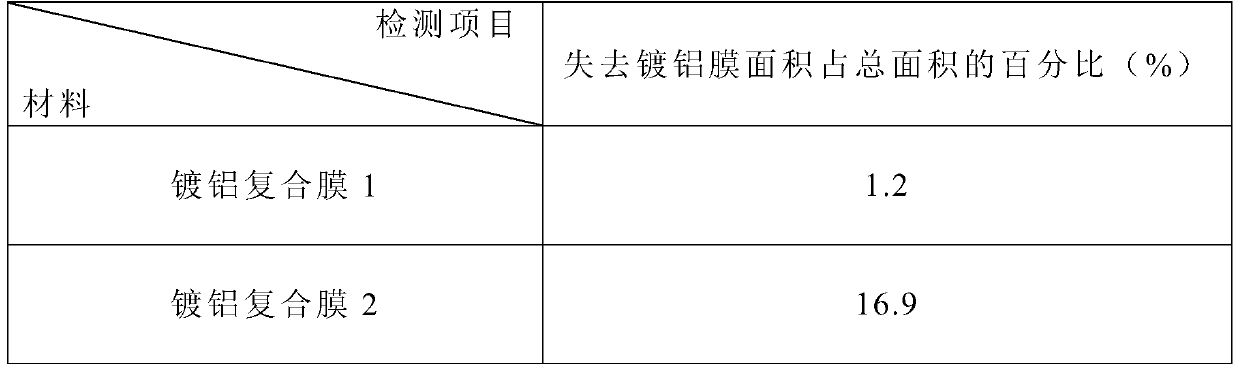

Method used

Image

Examples

Embodiment 1

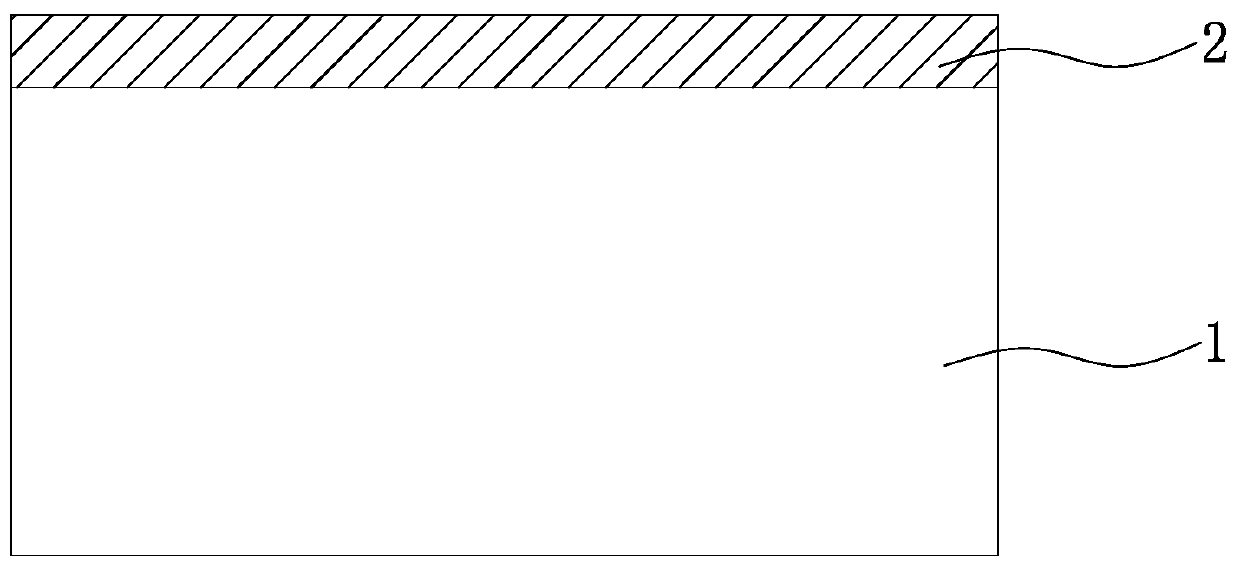

[0037] This embodiment provides a PE vacuum aluminized composite film, such as figure 1 As shown, it includes a PE composite base film 1 and an aluminum-coated film 2 connected to one side of the PE composite base film 1, and the PE composite base film 1 includes low-density polyethylene, 40 parts of low-density polyethylene, and 40 parts in mass parts respectively. Metallic polyethylene, 5 parts of surface adhesive resin, 15 parts of linear polyethylene, 3 parts of antioxidant, 3 parts of heat stabilizer, 3 parts of UV blocker and 3 parts of antiblocking agent.

[0038] Wherein, the surface adhesive resin comprises polyethylene adipate and a silane coupling agent, and the mass ratio of the polyethylene adipate to the silane coupling agent is 1:0.3; the low density polyethylene The melt flow rate is selected as 0.2g / 10min, and the density is 0.920g / cm 3 low-density polyethylene; the metallocene polyethylene is selected as a melt flow rate of 1.3g / 10min, a density of 0.940g / cm...

Embodiment 2

[0052] This embodiment provides a PE vacuum aluminized composite film, such as figure 1 As shown, it includes a PE composite base film 1 and an aluminized film 2 connected to one side of the PE composite base film 1, and the PE composite base film 1 includes low-density polyethylene, 30 parts of low-density polyethylene and 30 parts in mass parts respectively. Metallic polyethylene, 3 parts surface adhesive resin, 10 parts linear polyethylene, 1 part antioxidant, 1 part heat stabilizer, 1 part UV blocker and 1 part antiblocking agent.

[0053] Wherein, the surface adhesive resin comprises polyethylene adipate and a silane coupling agent, and the mass ratio of the polyethylene adipate to the silane coupling agent is 1:0.1; the low density polyethylene The melt flow rate is selected as 0.3g / 10min, and the density is 0.900g / cm 3 low-density polyethylene; the metallocene polyethylene is selected as a melt flow rate of 1.0g / 10min, a density of 0.920g / cm 3 The metallocene polyethy...

Embodiment 3

[0056] This embodiment provides a PE vacuum aluminized composite film, such as figure 1 As shown, including 35 parts by mass of low-density polyethylene, 35 parts of metallocene polyethylene, 4 parts of surface adhesive resin, 12 parts of linear polyethylene, 2 parts of antioxidant, 2 parts 2 parts of heat stabilizer, 2 parts of UV blocker and 2 parts of anti-blocking agent.

[0057] Wherein, the surface adhesive resin comprises polyethylene adipate and a silane coupling agent, and the mass ratio of the polyethylene adipate to the silane coupling agent is 1:0.2; the low density polyethylene The melt flow rate is selected to be 0.25g / 10min, and the density is 0.910g / cm 3 low-density polyethylene; the metallocene polyethylene is selected as a melt flow rate of 1.2g / 10min, a density of 0.930g / cm 3 The metallocene polyethylene; Antioxidant is PS-802 antioxidant; Thermal stabilizer can be selected commercially available products, such as organotin stabilizer; Ultraviolet blocking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com