3D screen protective film and preparation method thereof

A technology of screen protection film and protective film, which is applied in the direction of sub-office equipment, film/sheet adhesive, coating, etc., which can solve the problems of easy penetration, difficult volatilization, and severe odor when tearing off the adhesive surface of the release film. Achieve good hot press formability, improve edge warping and gray edges, and prevent solvent penetration and escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

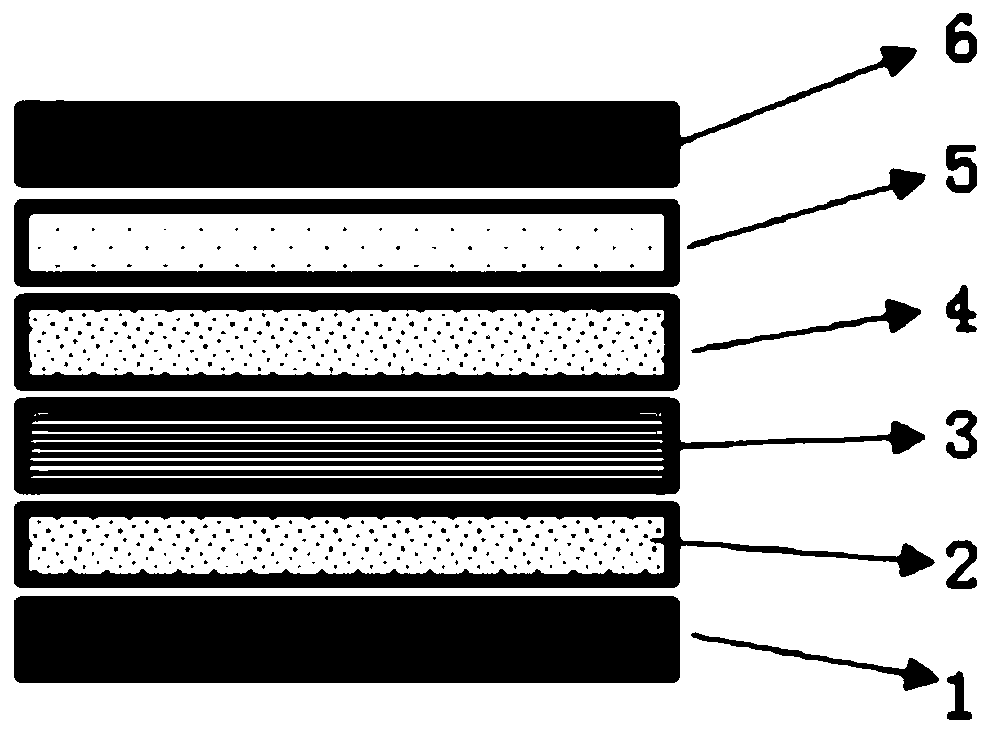

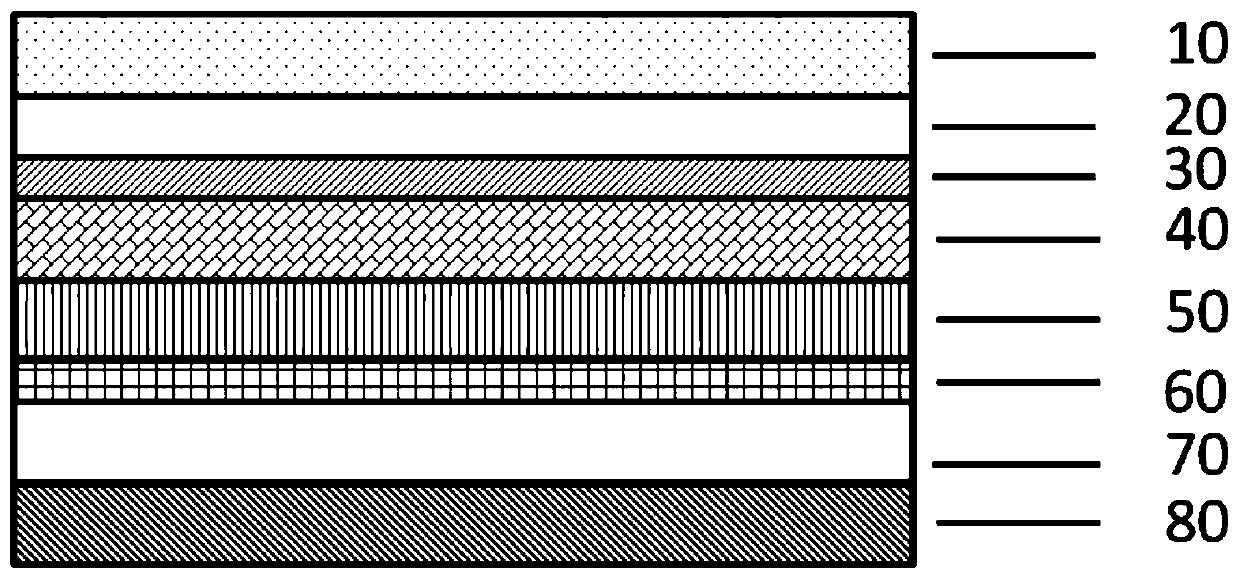

[0029] The invention provides a 3D curved screen protector, which has a multi-layer structure, such as figure 2 As shown, it includes the first substrate layer 10, the first pressure-sensitive adhesive protective layer 20, the hardened layer 30, the second optical grade substrate layer 40, the amorphous polymer elastomer substrate layer 50, the sealing coating layer 60 , a second protective layer of pressure sensitive adhesive 70 and a release film layer 80 .

[0030] Among them, the first substrate layer 10 and the release film layer 80 are transparent PET films, which have no special requirements on light transmittance and haze, and have a thickness of 50 μm; the first pressure-sensitive adhesive protective layer 20 is a low-viscosity silicone pressure-sensitive adhesive, The thickness is 10um, which is formed by a wet extrusion precision coating process; the hardened layer 30 is 2.0 μm thick, and is formed by a wet micro gravure roll precision coating process; the second o...

Embodiment 2

[0032] The 3D curved surface protection sticker structure provided in Example 1, wherein the first substrate layer 10 and the release film layer 80 are transparent PET films, with no special requirements for light transmittance and haze, and a thickness of 50 μm; the first pressure-sensitive adhesive protection Layer 20 is a low-viscosity silicone pressure-sensitive adhesive with a thickness of 8um, which is formed by a wet extrusion precision coating process; The material layer 40 is an optical-grade SRF film with a thickness of 80 μm; the amorphous polymer elastomer substrate layer 50 is a TPU coating with high light transmittance, low haze and yellowing resistance, with a thickness of 70 μm, and is extruded by a wet method. Formed by a precision coating process; the sealing coating 60 is polyacrylic resin with a glass transition temperature of about 80°C, with a thickness of 6 μm, and is formed by a wet micro-gravure roll precision coating process; the second pressure-sensit...

Embodiment 3

[0034] The 3D curved surface protection sticker structure provided in Example 1, wherein the first substrate layer 10 and the release film layer 80 are transparent PET films, with no special requirements for light transmittance and haze, and a thickness of 50 μm; the first pressure-sensitive adhesive protection Layer 20 is a low-viscosity silicone pressure-sensitive adhesive with a thickness of 10um, which is formed by wet extrusion precision coating process; hardened layer 30 is 1.8 μm thick, and is formed by wet micro gravure roller precision coating process; the second optical grade base The material layer 40 is an optical-grade PET film with a thickness of 23 μm; the amorphous polymer elastomer substrate layer 50 is a TPU coating with high light transmittance, low haze and yellowing resistance, with a thickness of 40 μm, and is extruded by a wet method. Formed by a precision coating process; the sealing coating 60 is polyacrylic resin with a glass transition temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com