Aluminum alloy with high strength, high conductivity, corrosion resistance, weldability and good thermal forming property and preparation method and application thereof

An aluminum alloy and thermoforming technology, which is applied in the field of aluminum alloy, can solve problems such as lack and achieve good thermoforming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

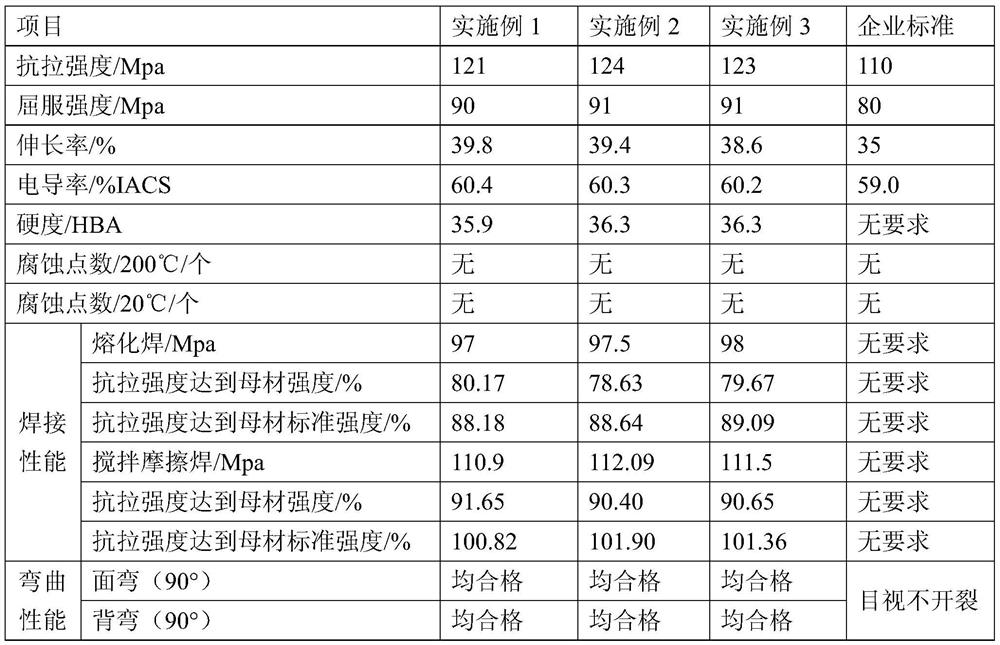

Examples

Embodiment 1

[0046] An aluminum alloy with high strength, high conductivity, corrosion resistance, weldability and good thermoformability, the aluminum alloy can be used to manufacture a magnetic levitation induction plate, and the aluminum alloy is composed of the following chemical components in mass fractions:

[0047]Si: 0.3503%, Fe: 0.5855%, Cu: 0.1510%, B: 0.0111%, Mn: 0.0023%, Mg: 0.0011%, Cr≤0.0021%, Zn≤0.0008%, Ti≤0.0011%, C: 0.0012%, Single impurity ≤ 0.03%, alloy impurity ≤ 0.10%, the balance is Al;

[0048] The aluminum alloy is prepared by the following preparation method:

[0049] (1) Casting treatment

[0050] Add aluminum ingots and molten aluminum in turn into the molten pool. The temperature of the molten aluminum is allowed to fluctuate within the range of 800-1000°C. When the temperature of the molten aluminum in the molten pool is 860-870°C, add Si, Fe, Cu, and B elements to continue heating and melting. Electromagnetic stirring device, until all the added elements a...

Embodiment 2

[0061] An aluminum alloy with high strength, high conductivity, corrosion resistance, weldability and good thermoformability, the aluminum alloy can be used to manufacture a magnetic levitation induction plate, and the aluminum alloy is composed of the following chemical components in mass fractions:

[0062] Si: 0.3515%, Fe: 0.5842%, Cu: 0.1500%, B: 0.0101%, Mn: 0.0020%, Mg: 0.0014%, Cr≤0.0023%, Zn≤0.0007%, Ti≤0.0013%, C: 0.0011%, Single impurity ≤ 0.03%, alloy impurity ≤ 0.10%, the balance is Al;

[0063] The aluminum alloy is prepared by the following preparation method:

[0064] (1) Casting treatment

[0065] Add aluminum ingots and molten aluminum in sequence to the melting pool of the melting furnace. The temperature of the molten aluminum is allowed to fluctuate within the range of 800-1000°C. When the temperature of the molten aluminum in the molten pool is 860-870°C, add Si, Fe, Cu, and B elements to continue heating and melting. At the same time, turn on the electr...

Embodiment 3

[0076] An aluminum alloy with high strength, high conductivity, corrosion resistance, weldability and good thermoformability, the aluminum alloy can be used to manufacture a magnetic levitation induction plate, and the aluminum alloy is composed of the following chemical components in mass fractions:

[0077] Si: 0.3542%, Fe: 0.5820%, Cu: 0.1503%, B: 0.0131%, Mn: 0.0025%, Mg: 0.0017%, Cr≤0.0019%, Zn≤0.0009%, Ti≤0.0010%, C: 0.0015%, Single impurity ≤ 0.03%, alloy impurity ≤ 0.10%, the balance is Al;

[0078] The aluminum alloy is prepared by the following preparation method:

[0079] (1) Casting treatment

[0080] Add aluminum ingots and molten aluminum in sequence to the melting pool of the melting furnace. The temperature of the molten aluminum is allowed to fluctuate within the range of 800-1000°C. When the temperature of the molten aluminum in the molten pool is 860-870°C, add Si, Fe, Cu, and B elements to continue heating and melting. At the same time, turn on the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com