2.5D protective film and preparation method thereof

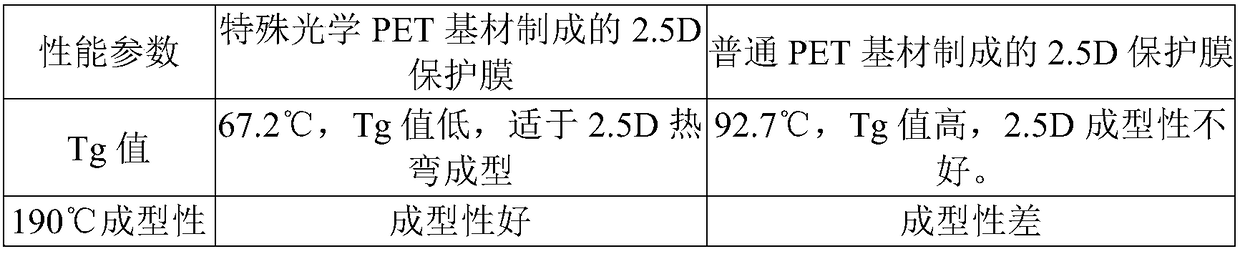

A technology of protective film and protective layer, which is applied in the direction of pressure-sensitive film/sheet, film/sheet-shaped adhesive, adhesive, etc., which can solve the problem of poor thermoforming of PET protective film, warped edges, and easy rebound and other problems, to achieve the effect of improving visual experience, firm fit, and excellent exhaust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

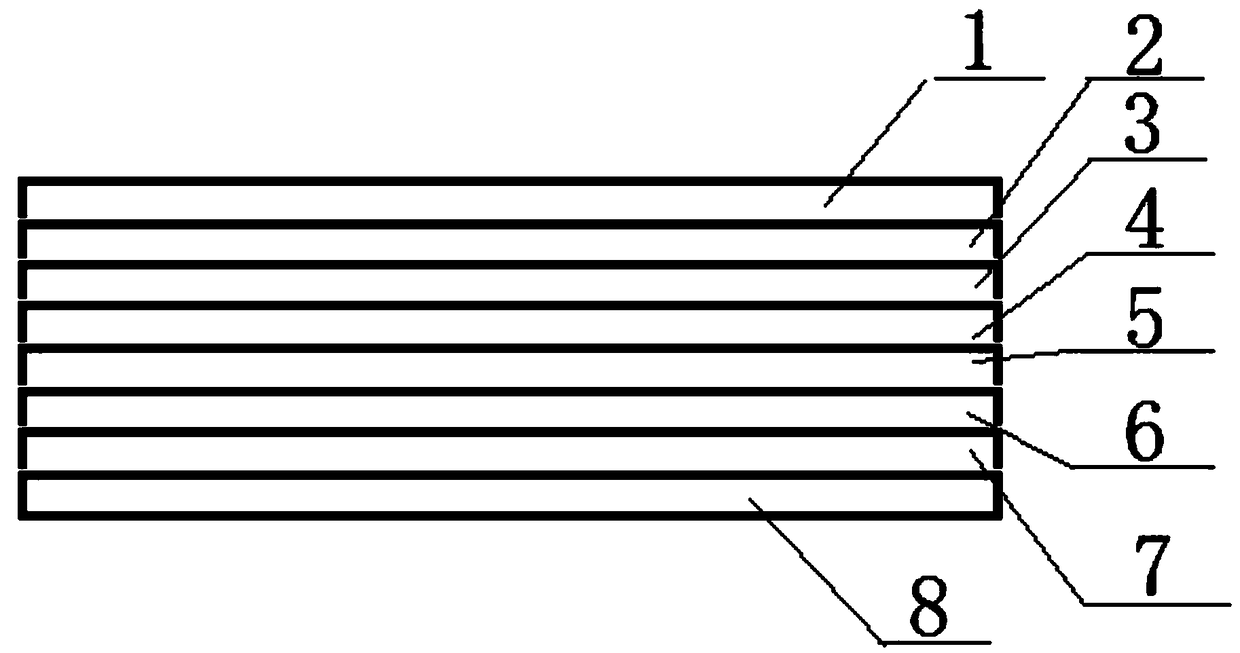

[0046] This embodiment provides a 2.5D protective film, such as figure 1 As shown, it is a multi-layer structure, with PET substrate layer 1, first silicone pressure-sensitive adhesive protective layer 2, polyacrylic resin hardened layer 3, first special optical grade PET substrate layer 4, OCA An optical polyacrylic adhesive layer 5 , a second special optical grade PET substrate layer 6 , a second silicone pressure-sensitive adhesive protective layer 7 and a PET fluorine release film layer 8 . in,

[0047] The thickness of the PET substrate layer 1 is 50 μm,

[0048] The thickness of the first silicone pressure-sensitive adhesive protective layer 2 is 10 μm,

[0049] The polyacrylic resin hardened layer 3 has a thickness of 3 μm,

[0050] The thickness of the first special optical PET substrate layer 4 is 50 μm,

[0051] The thickness of the OCA optical polyacrylic adhesive layer 5 is 20 μm,

[0052] The thickness of the second special optical PET substrate layer 6 is 50...

Embodiment 2

[0072] This embodiment provides a 2.5D protective film, such as figure 1 As shown, it is a multi-layer structure, with PET substrate layer 1, first silicone pressure-sensitive adhesive protective layer 2, polyacrylic resin hardened layer 3, first special optical grade PET substrate layer 4, OCA An optical polyacrylic adhesive layer 5 , a second special optical grade PET substrate layer 6 , a second silicone pressure-sensitive adhesive protective layer 7 and a PET fluorine release film layer 8 . in,

[0073] The thickness of the PET substrate layer 1 is 50 μm,

[0074] The thickness of the first silicone pressure-sensitive adhesive protective layer 2 is 10 μm,

[0075] The thickness of the polyacrylic resin hardened layer 3 is 2.5 μm,

[0076] The thickness of the first special optical PET substrate layer 4 is 50 μm,

[0077] The thickness of the OCA optical polyacrylic adhesive layer 5 is 10 μm,

[0078] The thickness of the second special optical PET substrate layer 6 is...

Embodiment 3

[0098] This embodiment provides a 2.5D protective film, such as figure 1 As shown, it is a multi-layer structure, with PET substrate layer 1, first silicone pressure-sensitive adhesive protective layer 2, polyacrylic resin hardened layer 3, first special optical grade PET substrate layer 4, OCA An optical polyacrylic adhesive layer 5 , a second special optical grade PET substrate layer 6 , a second silicone pressure-sensitive adhesive protective layer 7 and a PET fluorine release film layer 8 . in,

[0099] The thickness of the PET substrate layer 1 is 50 μm,

[0100] The thickness of the first silicone pressure-sensitive adhesive protective layer 2 is 10 μm,

[0101] The polyacrylic resin hardened layer 3 has a thickness of 3 μm,

[0102] The thickness of the first special optical PET substrate layer 4 is 50 μm,

[0103] The thickness of the OCA optical polyacrylic adhesive layer 5 is 20 μm,

[0104] The thickness of the second special optical PET substrate layer 6 is 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com