Biodegradable thermal shrinkage film and preparation method thereof

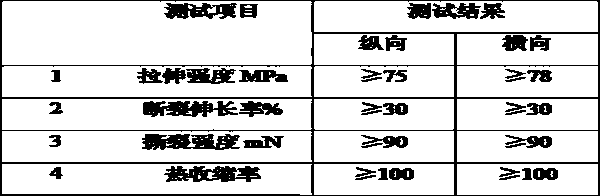

A heat-shrinkable film, biological technology, used in flat products, other household appliances, applications, etc., can solve the problems of polluted environment, non-degradable materials, etc., and achieve the effect of high mechanical strength and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A biodegradable heat-shrinkable film, which is mainly made of the following raw materials in parts by weight: 90 parts of poly-3-hydroxybutyrate-4-hydroxybutyrate, 1 part of HANKINS NCP-2, and 2 parts of zinc stearate , 1 part of dibutyl phthalate, 2 parts of PS-802.

[0020] The preparation method of the biodegradable heat-shrinkable film comprises the following steps: weighing the above raw materials in parts by weight; adding poly-3-hydroxybutyrate-4-hydroxybutyrate and HANKINS NCP-2 to the reaction kettle at 75°C , zinc stearate, dibutyl phthalate, PS-802 and stirred at 150rpm for 10min; the temperature in the reactor was raised to 290°C, and the pressure was lowered to below 90pa. body, and then extrude the prepared polymer melt, pelletize, and dry to obtain polyester chips; melt and extrude the above polyester chips, die casting, casting sheet winding, biaxial stretching, cooling and setting, and thickness measurement , Rewinding, slitting and rewinding, packagin...

Embodiment 2

[0023] A biodegradable heat-shrinkable film, mainly made of the following raw materials in parts by weight: 100 parts of poly-3 hydroxybutyrate, 5 parts of HANKINS NCP-2, 5 parts of ethylene bis stearamide, phthalate 3 parts of dibutyl formate, 5 parts of PS-802.

[0024] The preparation method of the biodegradable heat-shrinkable film includes the following steps: weighing the above-mentioned raw materials in parts by weight; adding poly-3 hydroxybutyrate, HANKINS NCP-2, ethylene bishard Fatty amide, dibutyl phthalate, PS-802 and stirred at 200rpm for 20min; the temperature in the reactor was raised to 300°C, and the pressure was lowered to below 90pa, and reacted under this condition for 3h to obtain a polymerized melt, and then The prepared polymer melt is extruded, pelletized, and dried to obtain polyester chips; the above-mentioned polyester chips are melt-extruded, die-cast, cast sheets wound, biaxially stretched, cooled and shaped, thickness measured, and rolled , Slit...

Embodiment 3

[0027] A biodegradable heat-shrinkable film is mainly made of the following raw materials in parts by weight: 95 parts of poly-3-hydroxybutyrate-4-hydroxybutyrate, 3 parts of HANKINS NCP-2, 3 parts of high melting point paraffin, 2 parts of dibutyl phthalate, 3 parts of PS-802.

[0028] The preparation method of the above-mentioned biodegradable heat-shrinkable film comprises the following steps: weighing the above-mentioned raw materials in parts by weight; adding poly-3-hydroxybutyrate-4-hydroxybutyrate, HANKINS NCP- 2. High melting point paraffin, dibutyl phthalate, PS-802 and stir at 180rpm for 17min; raise the temperature in the reactor to 295°C, lower the pressure to below 90pa, and react under this condition for 2h to obtain a polymer melt body, and then extrude the prepared polymer melt, pelletize, and dry to obtain polyester chips; melt and extrude the above polyester chips, die casting, casting sheet winding, biaxial stretching, cooling and setting, and thickness mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com