Method for molding and manufacturing metal pipe

A manufacturing method and technology for metal pipe fittings, applied in the field of forming and manufacturing metal pipe fittings, can solve the problems of limited pipe material, difficulty in ensuring dimensional accuracy, and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable your examiner to have a further in-depth understanding of the present invention, a preferred embodiment is hereby exemplified, and is described in conjunction with the drawings as follows:

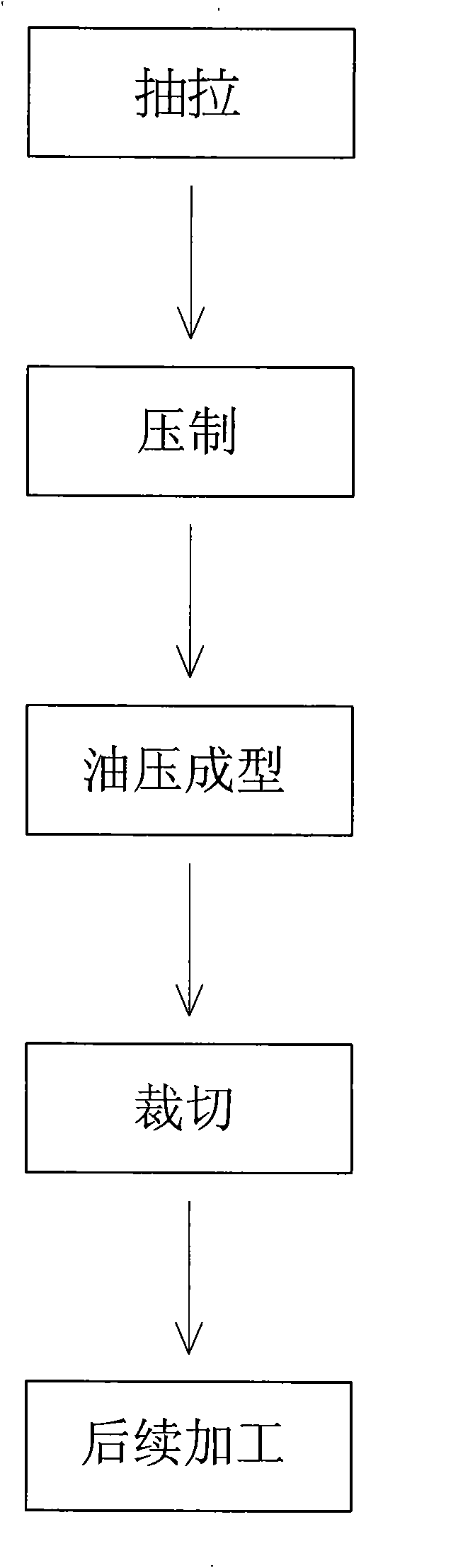

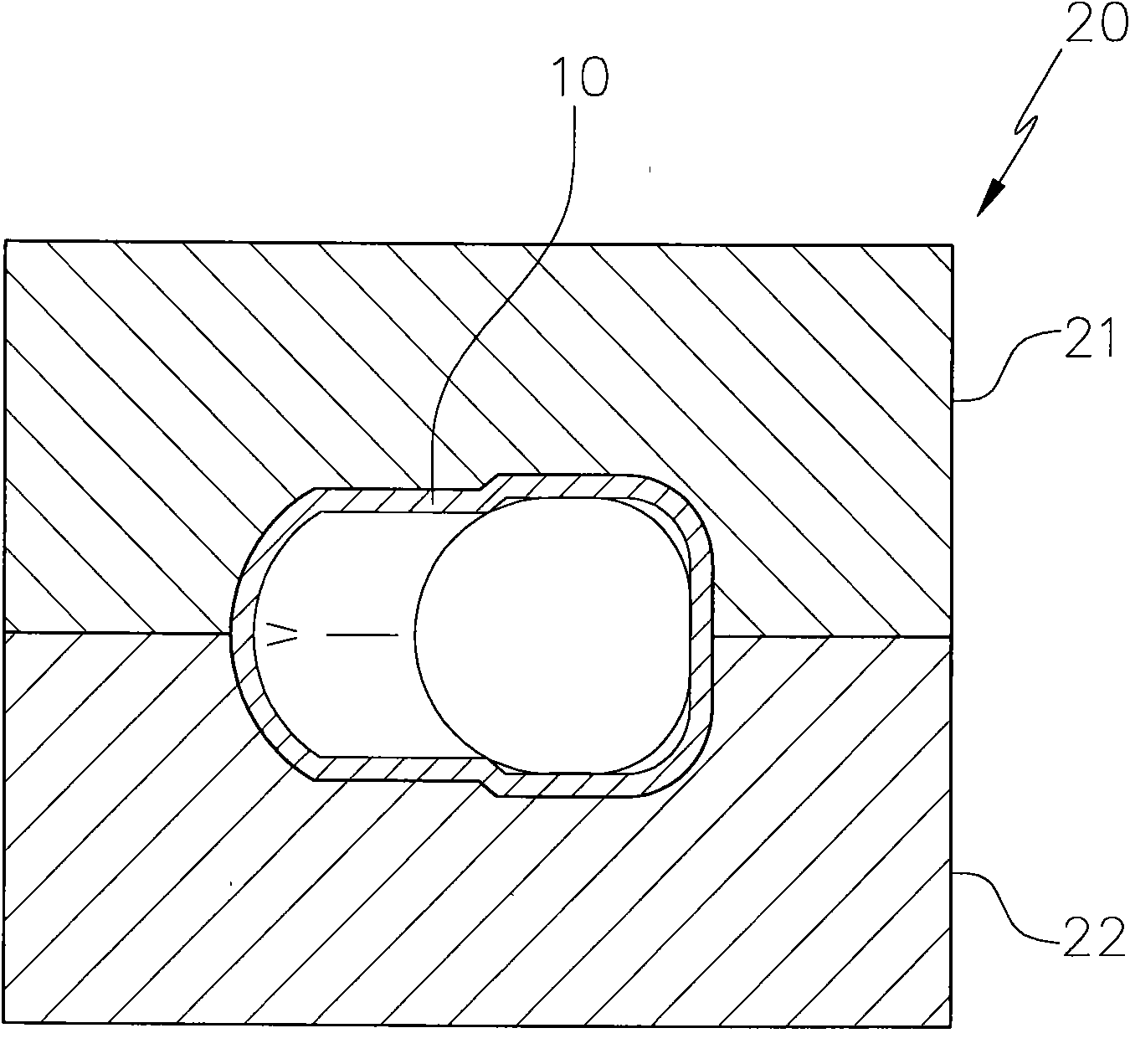

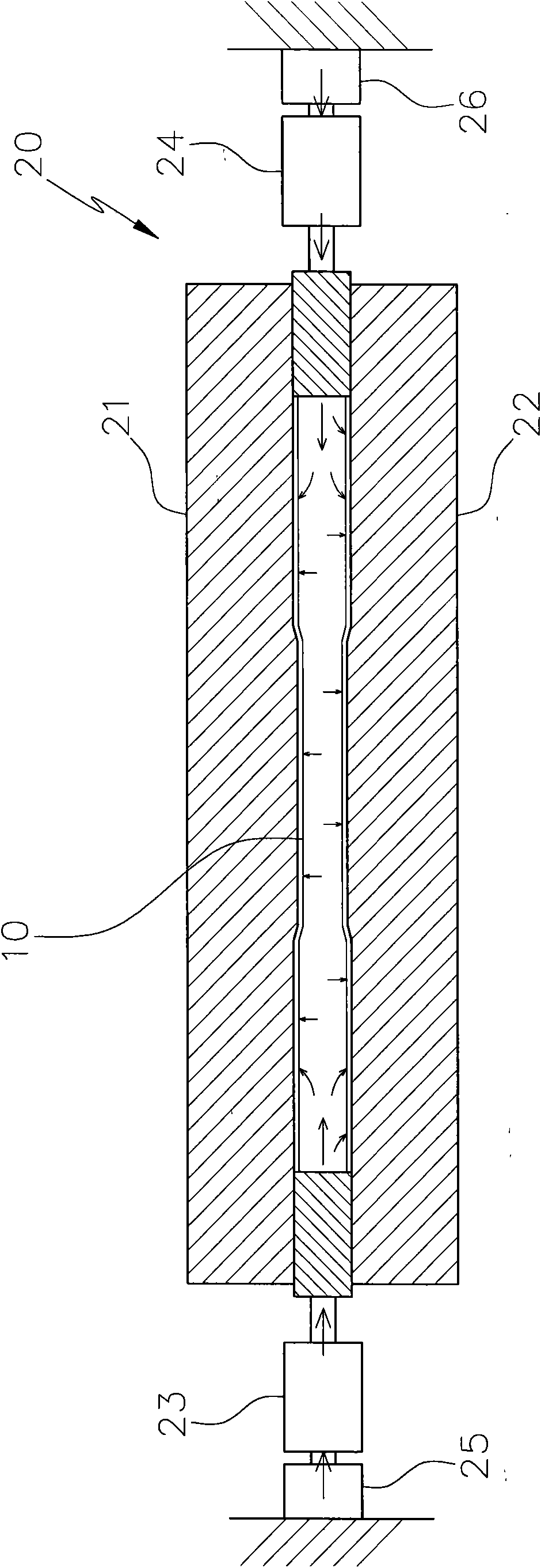

[0046] see Figure 4 , Figure 5 As shown, the forming method of metal pipe fittings of the present invention firstly provides a pipe made of metal material, and performs preforming means with the pipe material to preform a pipe fitting 30 rough blanks, and the pipe material can be expanded by a pipe expansion mold , pipe shrinking die or pipe bending die to carry out preliminary pipe expansion, pipe shrinking or bending; The rough billet 30 has a first side end 301, a second side end 302, and an arc segment 303; then, the rough billet 30 of the pipe fitting is subjected to a first heat treatment method to increase the ductility of the rough billet 30 of the pipe fitting; in this embodiment Among them, the rough embryo of the pipe fitting 30 is subjected to quen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com