Preparing method capable of weaving continuous fiber enhanced thermoplasticity prepreg tape and product

The technology of continuous fiber and prepreg tape is applied in the field of preparation of woven continuous fiber thermoplastic prepreg tape. The effect of increasing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] The accompanying drawings further describe the present invention in detail, so that those skilled in the art can implement it with reference to the description. It should be understood that after reading the content taught by the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0030] In the description of the present invention, it should be noted that the terms "feeding conduit", "hollow splitter", and "discharge die" are only for the convenience of describing the present invention and simplifying the description, for those of ordinary skill in the art That is to say, on the premise of not departing from the principle of the present invention, some improvements and modifications can also be made to the present invention, and these improvements and modifications also fall within the protection sc...

Embodiment 1

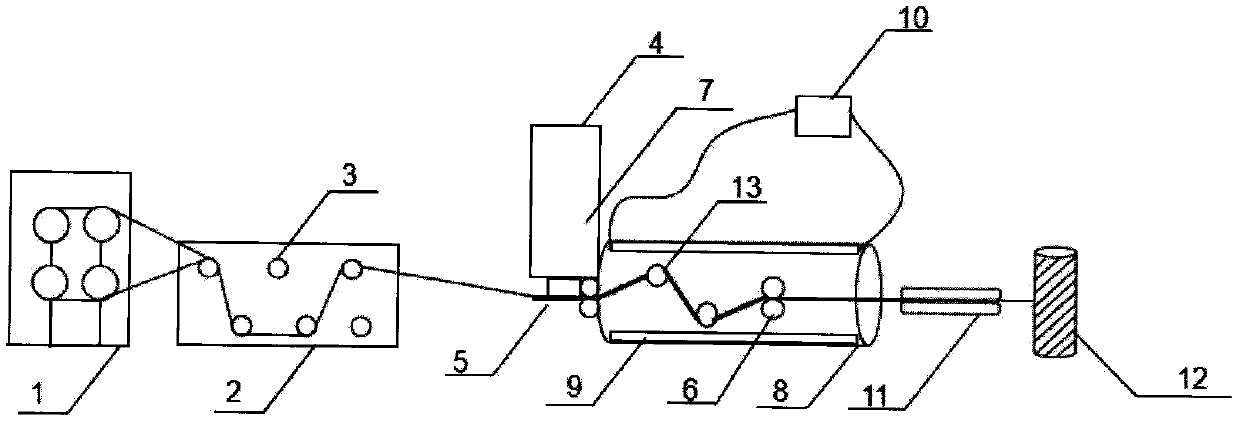

[0035] A preparation method and product of a weavable continuous fiber thermoplastic prepreg tape, such as figure 1 As shown, the rewinding frame 1, the yarn dividing frame 2, the screw extruder 4, the meshing roller 6, the heating sleeve 8, the drafting roller 13, the meshing roller 6, the traction machine 11, and the winding machine 12 are arranged in order . The 612tex continuous glass fiber is led out from the bobbin frame 1, passes through the splitting pins on the splitter frame 2, and passes through the feeding conduit of the head 5 of the screw extruder. The feeding conduit is the channel of the fiber and is located In the center, the end of the conduit is connected to the discharge die.

[0036] Put the LDPE pellets into an 80°C constant temperature oven, dry for 4 hours, put them into the screw extruder 4 barrels, set the temperature of each section to 170°C, 180°C, 190°C, 185°C, 180°C, and set the extrusion frequency 1.5Hz, the frequency of tractor 11 is set to 8H...

Embodiment 2

[0038]A preparation method and product of a weavable continuous fiber thermoplastic prepreg tape, such as figure 1 As shown, the rewinding frame 1, the yarn dividing frame 2, the screw extruder 4, the heating sleeve 8, the meshing roller 6, the tractor 11, and the winding machine 12 are arranged in sequence. The PP / glass fiber mixed yarn with a mass ratio of 880tex of 50 / 50 is drawn from the rewinding frame 1, passes through the splitting pin on the splitting frame 2, and passes through the feeding conduit of the head 5 of the screw extruder, and the feeding conduit is The fiber channel is located in the center of the hollow splitter, and the end of the conduit is connected to the discharge die. The hollow splitter is filled with heat-insulating fillers to prevent the PP / glass fiber mixed yarn from melting prematurely and blocking the feeding conduit, which hinders drafting.

[0039] Put the PP pellets in an 80°C constant temperature oven, dry for 4 hours, and put them into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com