Bipolar plate manufacturing device and method based on positive and negative pressure auxiliary forming

A technology for manufacturing devices and manufacturing methods, which is applied in the field of bipolar plate manufacturing devices, and can solve the problems that the forming quality of bipolar plates is difficult to be accurately controlled, the shape and dimensional accuracy of thin plates are difficult to meet the requirements, and the ultimate strain in the plane strain region of the sheet metal is low, etc. problems, to achieve the effects of shortening the production cycle, easy promotion, and reducing the phenomenon of sheet springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

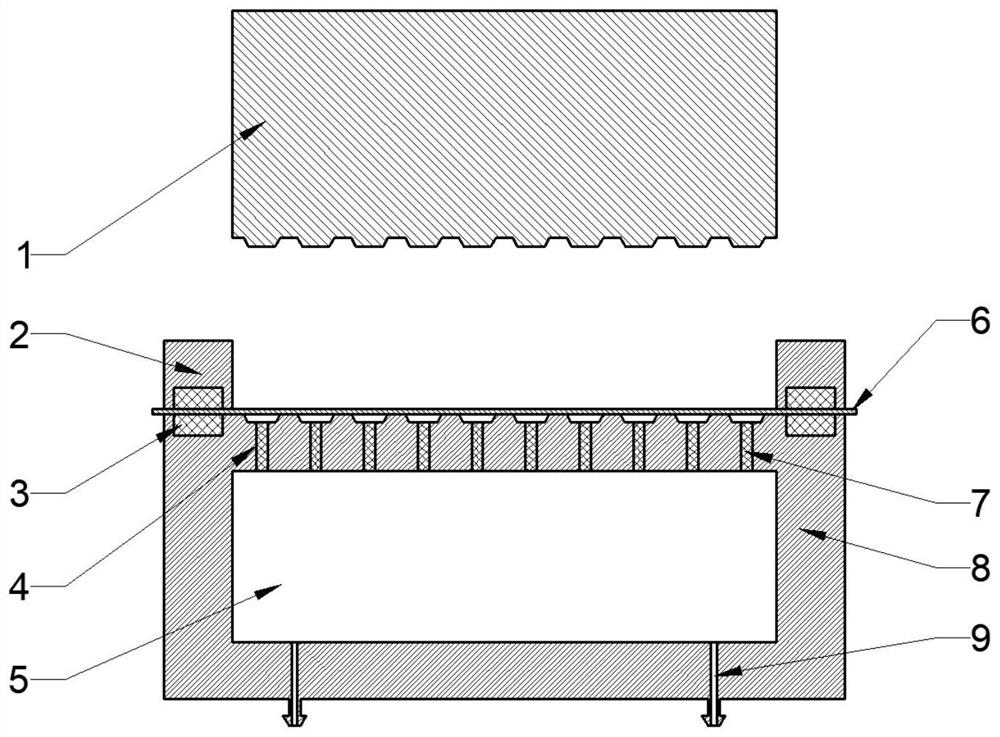

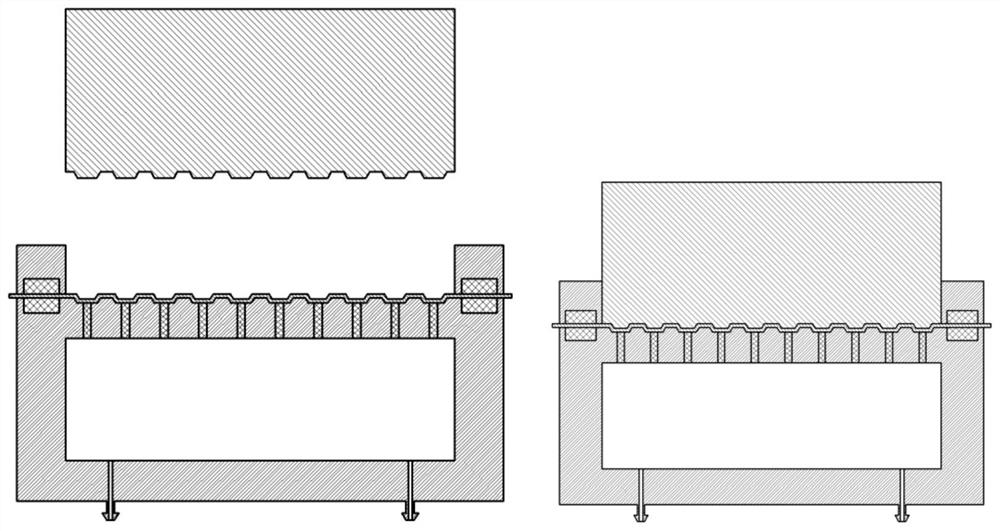

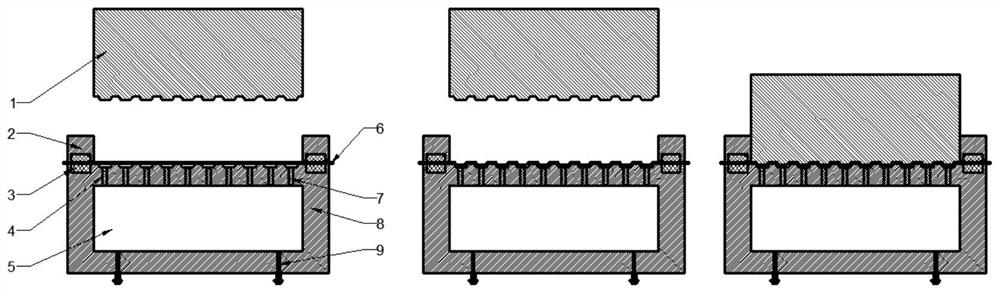

[0037] see Figure 1-2 , a bipolar plate manufacturing device based on positive and negative pressure assisted forming of the present invention, including an upper mold 1 and a lower mold 8 that are both connected to the machine tool;

[0038] The bipolar plate 6 is fixed on the upper surface of the lower die 8 by the blank holder 2 through bolts for stamping;

[0039] The lower surface of the upper mold 1 and the upper surface of the lower mold 8 are provided with grooves corresponding to the stamped bipolar plate 6;

[0040] The inside of the lower mold 8 includes an air cavity 5 for storing gas and maintaining air pressure;

[0041] The air cavity 5 is connected to an external air source through the air inlet and outlet holes 9 of the lower mold 8;

[0042] The upper part of the wall of the air cavity 5 is provided with an air hole 4;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com