Reel-to-reel hot rolling forming device for fine structures of polymer thin film products

A polymer film and microstructure technology, applied in the field of polymer processing, can solve the problems of reduced tension force, reduced microstructure forming accuracy, difficulty in demolding, etc., and achieves the effect of avoiding tension and breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

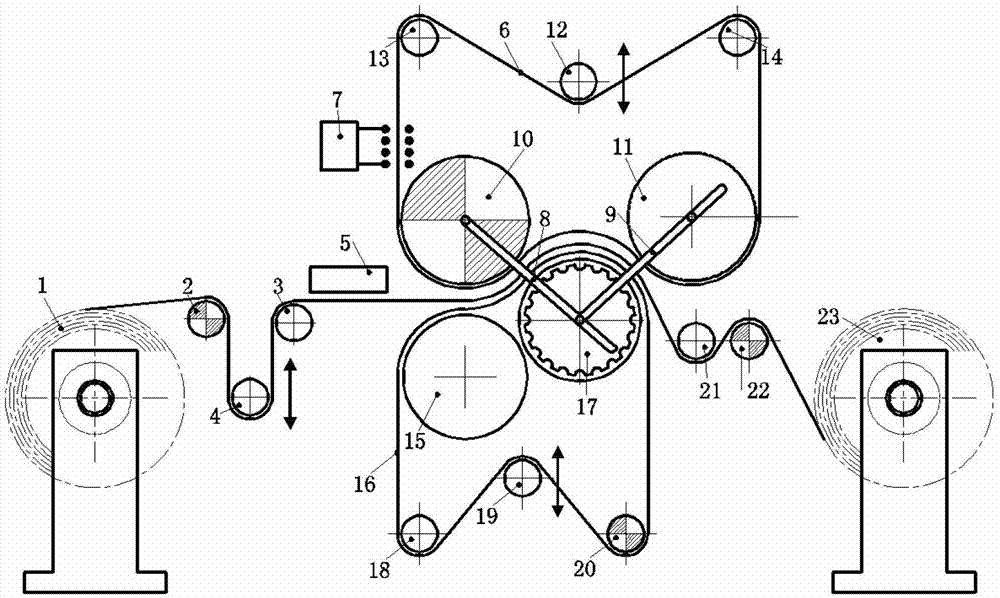

[0030] Such as figure 1As shown, the microstructure roll-to-roll thermal roll forming device for polymer film products includes a frame, an unwinding module, a preheating module, a forming / shape maintaining module, a tension adjustment module, and a winding module. The frame is mechanically connected with the preheating module, the forming / shape-retaining module, and the tension regulating module, and the tension regulating module is connected with the forming / shape-retaining module; the film substrate to be processed is unrolled by the unwinding module , after being preheated by the preheating module in turn, it enters the forming / shape keeping module for hot pressing and then cools and forms, and after finishing the embossing, it is wound in the winding module.

[0031] The unwinding module is an unwinding roller 1, and the driving roller b2, the tension roller c4 and the transmission roller e3 are arranged in sequence after the unwinding roller 1, and the rewinding module i...

Embodiment 2

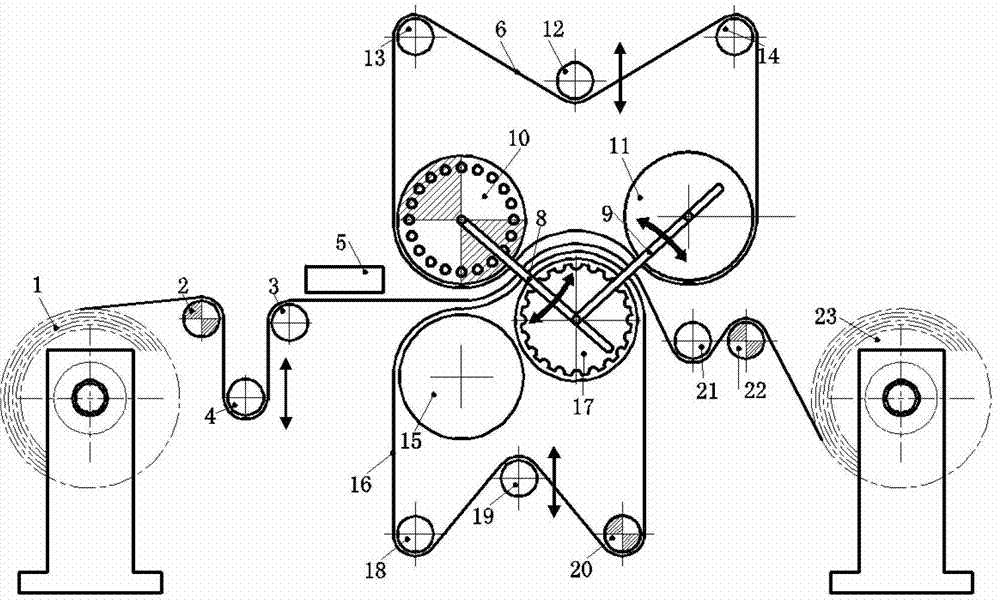

[0049] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that no inductive local heating device is provided; the forming roller 10 has a built-in electric heating wire to control its surface temperature above the glass transition temperature range of the substrate; the cooling roller 17 (in this embodiment is water-cooled roller) to provide cooling.

[0050] The cooling roller 17 is connected with the freezing equipment.

[0051] With the polymer film PET material with a thickness of 0.2mm as the base material, the working process of the present embodiment is divided into the following steps:

[0052] (1) The PET film with a thickness of 0.2mm is sent out from the unwinding roller 1, passes through the driving roller b2, the tension roller c4 and the transmission roller e3, passes under the ultraviolet preheating device 5, and then penetrates into the mold belt and shape-preserving A "sandwich" structure is formed between the belts. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com