Method for bending and cutting plate with notch

A cutting method and plate technology, which is applied in the field of plate processing, can solve problems such as the inability to satisfy the bending arc and the inability to guarantee the cutting quality, and achieve the effects of low labor intensity of workers, reduction of labor intensity of workers, and assurance of bending accuracy

Inactive Publication Date: 2012-06-27

TAIYUAN HEAVY IND

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Provide a bending and cutting method for a plate with a notch, and solve the technical problem that the existing production method cannot meet the bending arc when ensuring the cutting quality, and cannot guarantee the cutting quality when meeting the bending arc

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

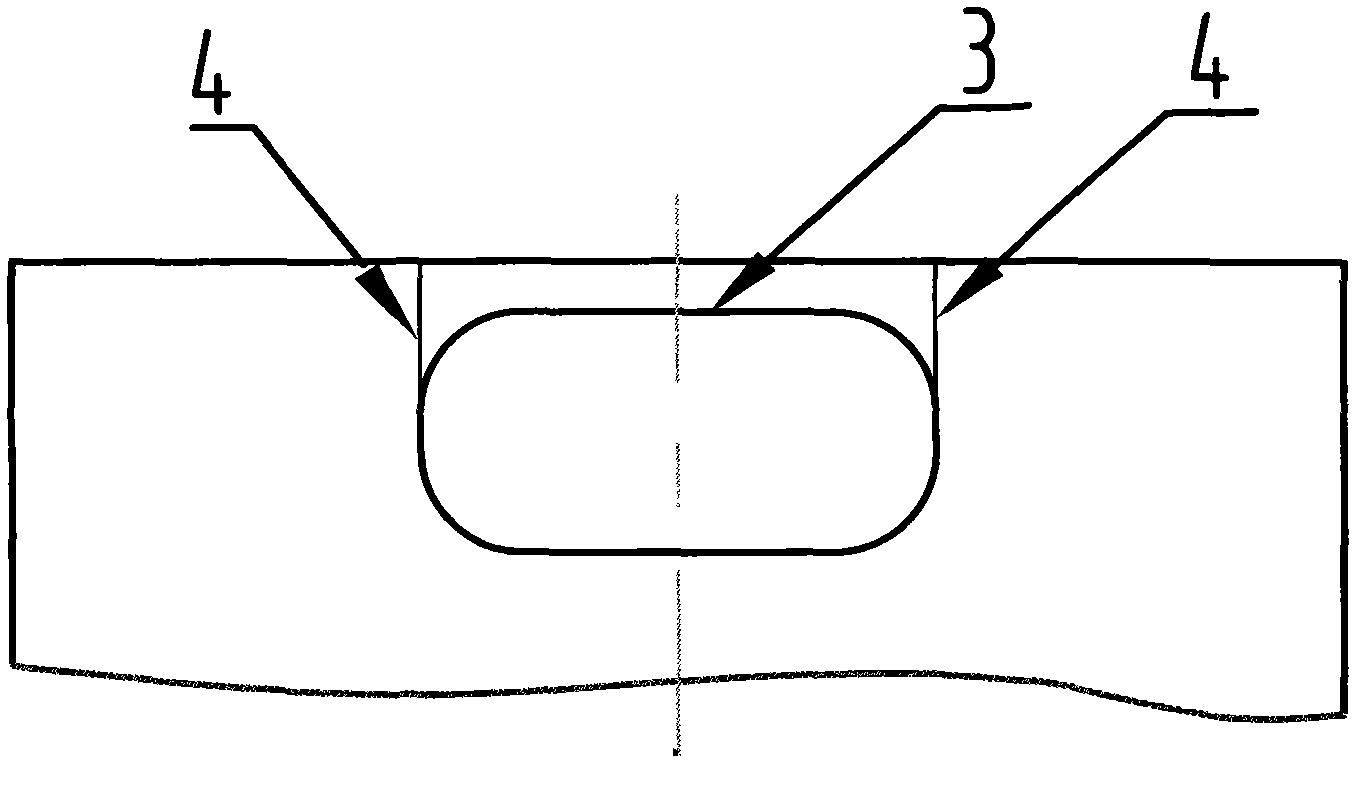

[0016] Such as image 3 As shown, a bending and cutting method with a notch, the specific steps are as follows:

[0017] ① CNC cutting square hole 3 on the plate from the root of the gap;

[0018] ② Stamping and bending according to the design requirements to the assembly requirements;

[0019] ③ Manually cut the excess plate along the sides 4 of the square hole 3 into gaps that meet the assembly requirements.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A method for bending and cutting a plate with a notch relates to a method for machining a plate and solves the technical problem that an existing manufacturing method cannot meet the requirement on bending radian while ensuring cutting quality, and cannot ensure cutting quality while meeting the requirement on bending radian. The method includes the specific steps: firstly, cutting a square hole at the root of the notch on the plate by means of numerical control; secondly, stamping and bending the plate to meet assembly requirements according to design requirements; and thirdly, manually cutting a redundant portion of the plate into the notch meeting assembly requirements along two sides of the square hole. The method is used for bending and cutting the plate with the notch, not only can meet the requirement of the plate with the notch on radian after bending, but also can ensure cutting quality, and reduces the labor intensity of workers.

Description

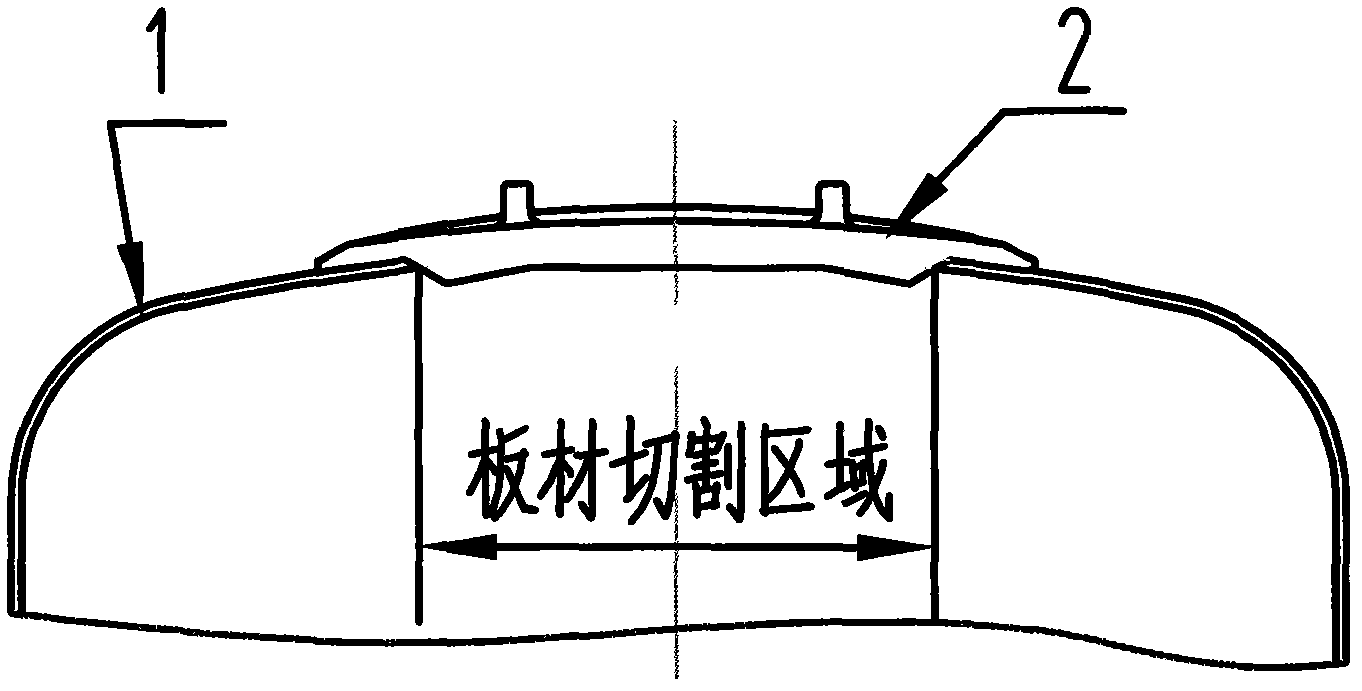

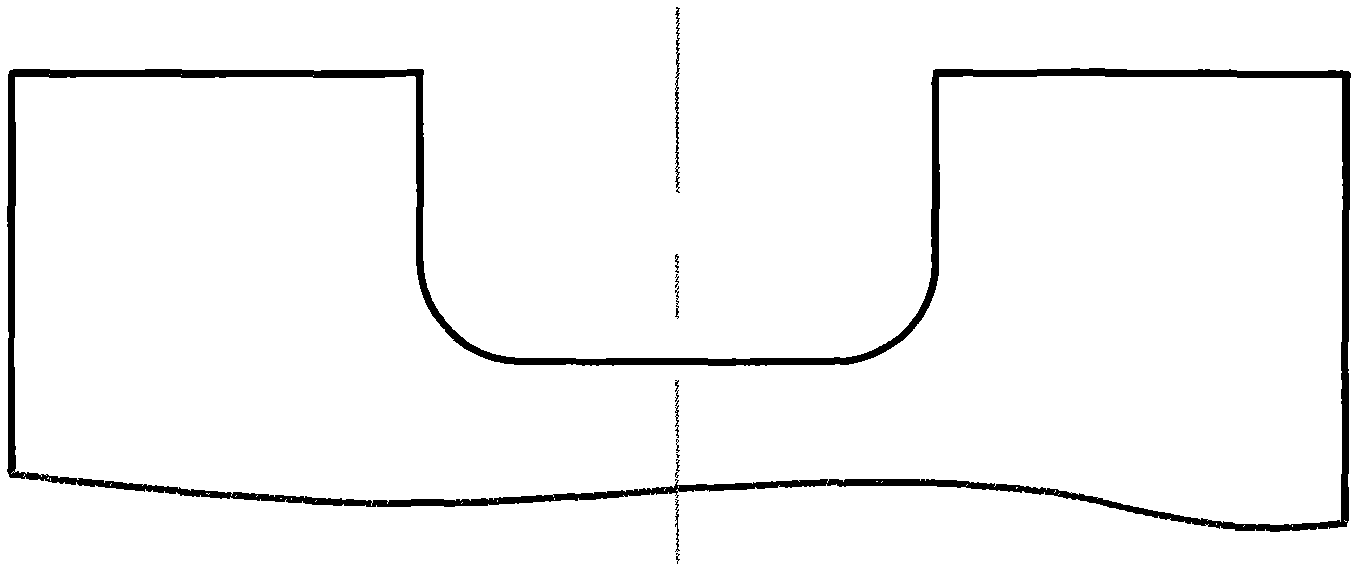

technical field [0001] The invention relates to a processing method for plates, in particular to a bending cutting method for plates with notches. Background technique [0002] Such as figure 1 The shown special container is fixed together by a curved plate 1 with a notch and an inserting plate 2, and there must be no gap between the plate 1 and the inserting plate 2. Therefore, there are strict requirements on the bending radian of the plate 1, and the production method of the curved plate with notches is as follows: [0003] Option 1. First cut the gap of the board according to the assembly size requirements (see figure 2 ), and then press and bend the sheet. Disadvantages are: due to the gaps cut by CNC on the board, the arc cannot be well controlled during bending. After assembly, the gap between the board and the insert board is relatively large, which cannot guarantee the stability of the structure, and at the same time causes a large amount of repair work. [000...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P15/00

Inventor 刘李梅崔敏民张林威肖利民罗瑞星李海军

Owner TAIYUAN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com