Hydraulic plate bending machine

A technology of bending machine and hydraulic plate, applied in the field of hydraulic sheet metal bending machine, can solve the problems of low machining accuracy, and achieve the effects of reasonable structure design, improved mechanization degree and high transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

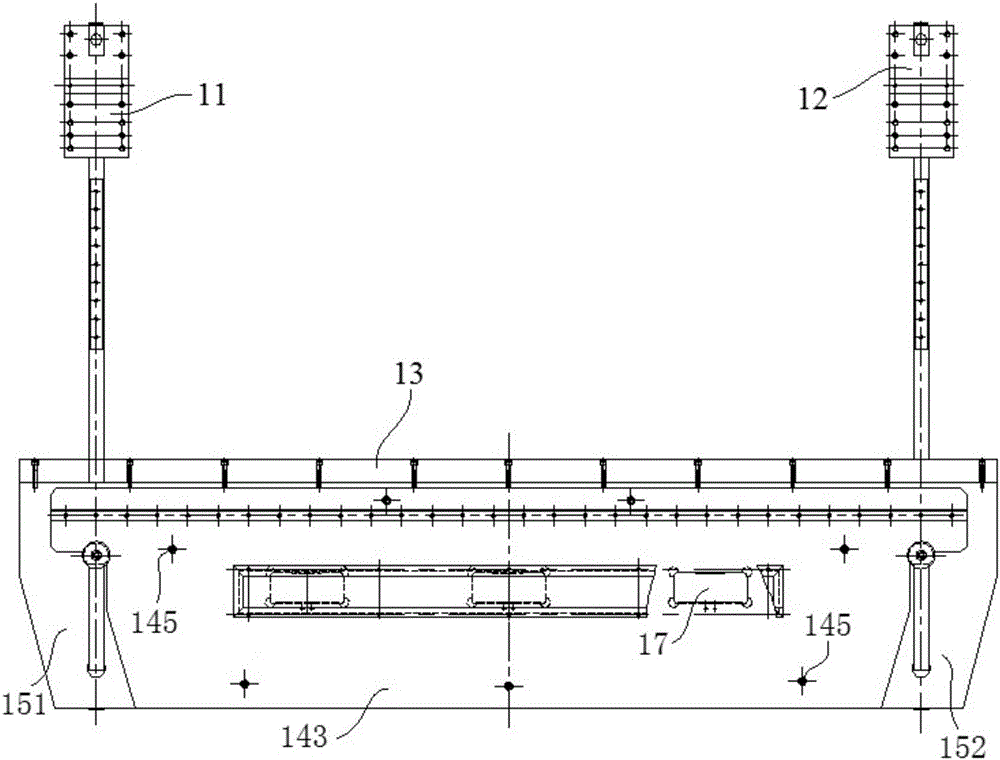

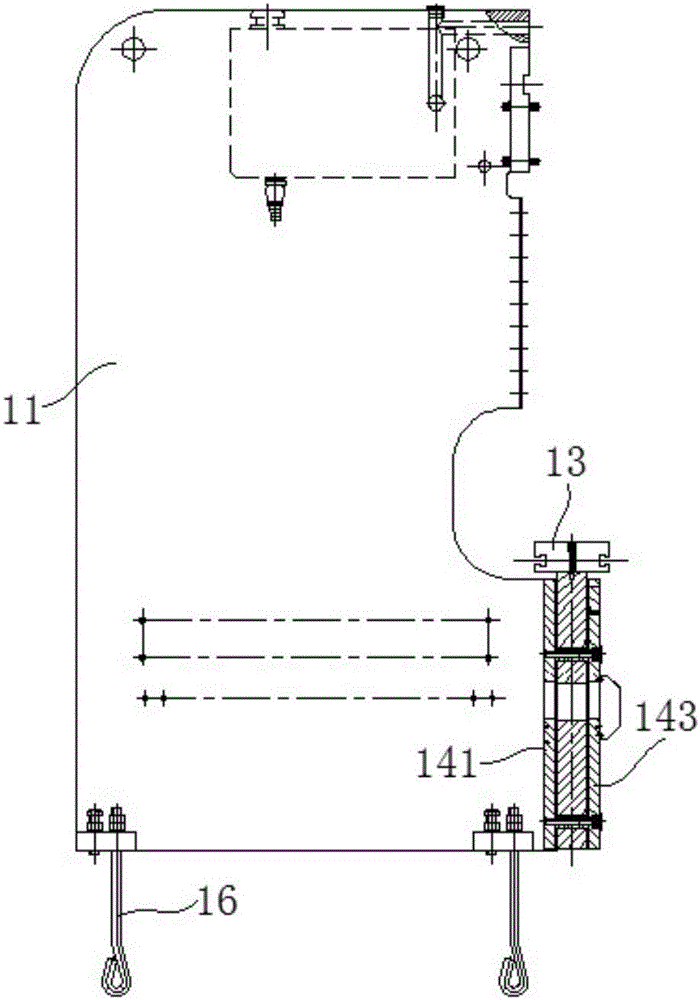

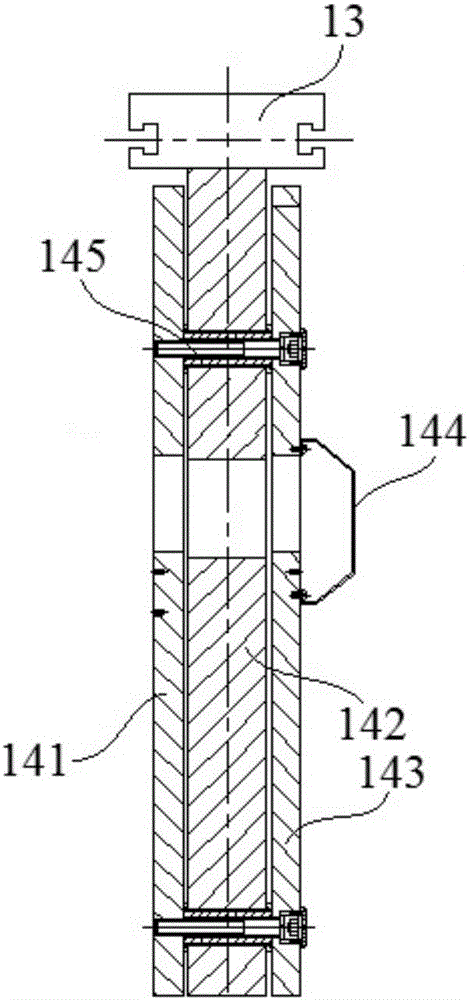

[0042] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 , a hydraulic sheet metal bending machine in this embodiment includes a frame, a slider assembly, a slider stroke adjustment mechanism, a synchronization mechanism and a backgauge mechanism.

[0043] Such as figure 1 , figure 2 and image 3 As shown, the frame in this embodiment includes a first wallboard 11, a second wallboard 12, a workbench panel 13, a rear vertical board 141, a main vertical board 142, a front vertical board 143, a casing 144, and locking pins 145. The first side vertical plate 151, the second side vertical plate 152, the anchor bolts 16 and the compensation cylinder 17, wherein: the rear vertical plate 141 and the front vertical plate 143 are vertically arranged in parallel, and the rear vertical plate 141 and the A main vertical board 142 is installed between the front vertical boards 143, a work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com