Method for bending metal pipe as well as equipment for implementing method

A technology for bending metal and hinges, which is applied in the field of bending metal pipes, can solve the problems of difficult control of the bending angle of metal pipes, inaccurate methods, and unstable quality, and achieve labor cost savings, simple equipment structure, and accurate bending angles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

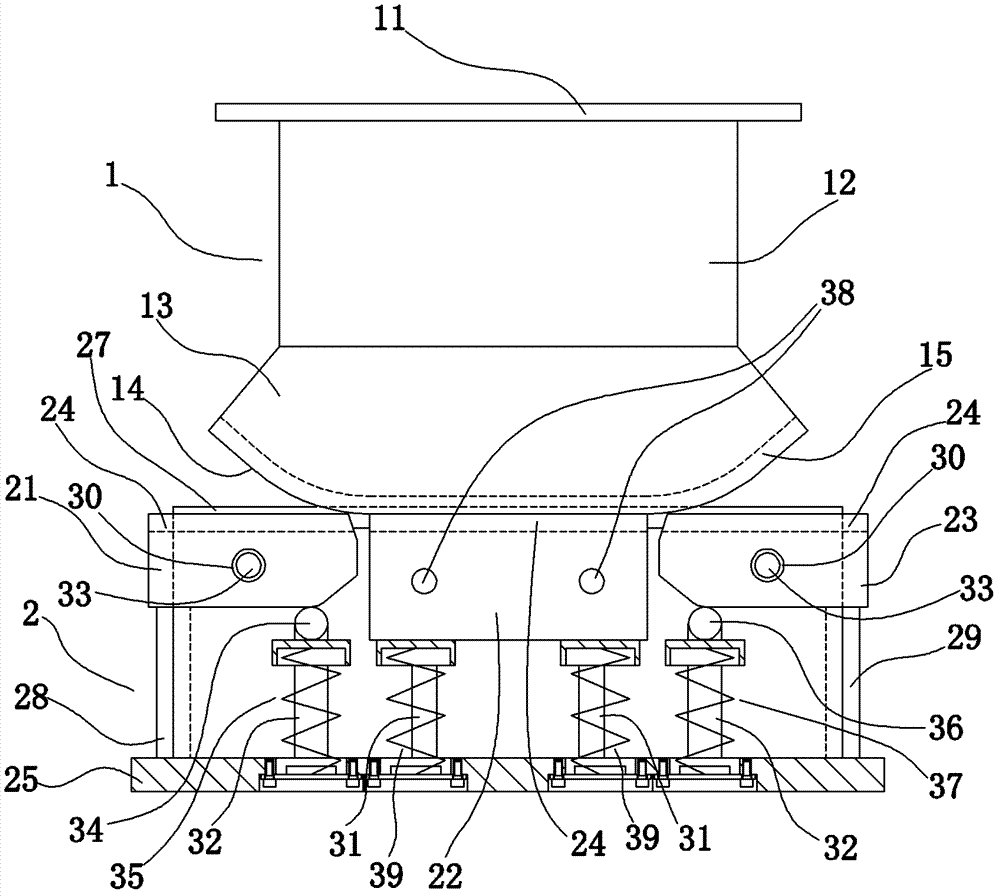

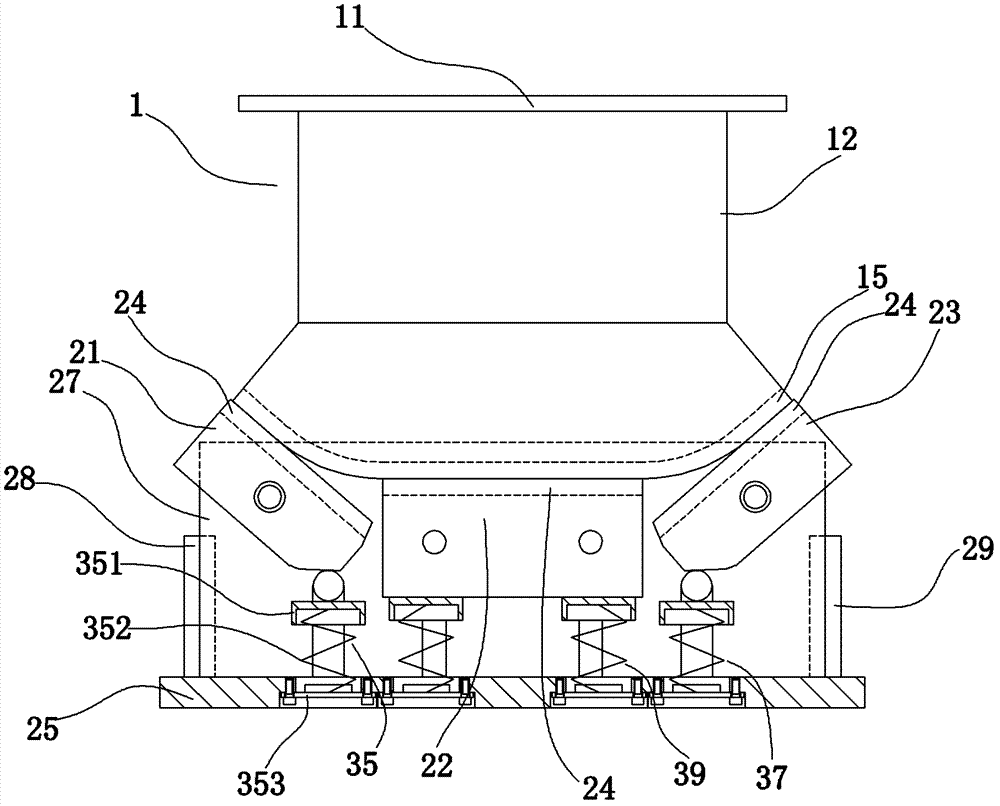

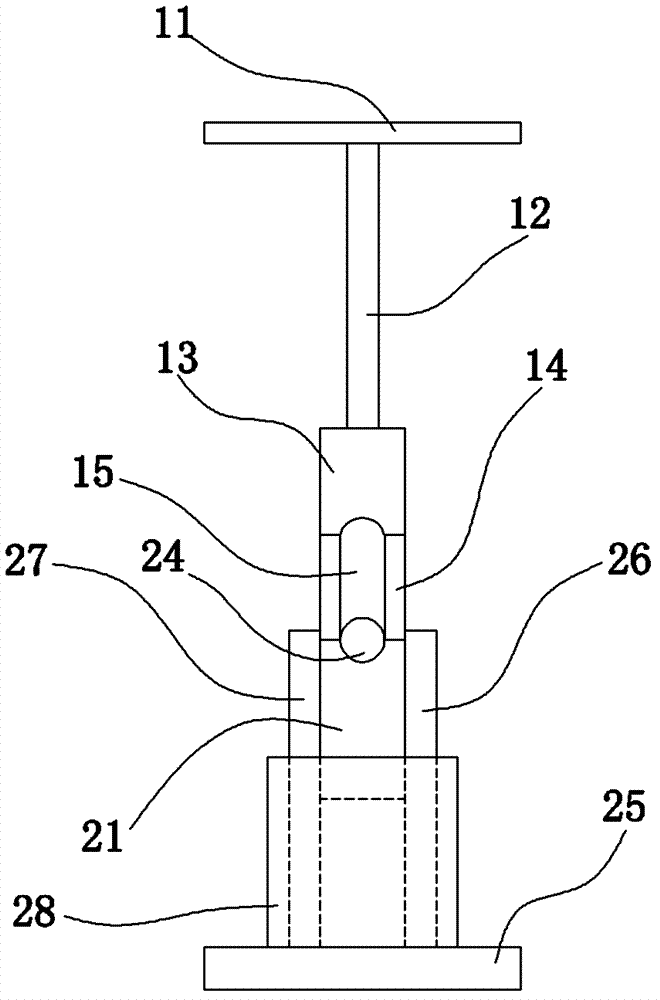

[0027] Example: see Figure 1 to Figure 3,in figure 1 It is a structural schematic diagram when the upper mold in the equipment of the present invention contacts the metal pipe placed on the lower mold, figure 2 It is a schematic diagram of the structure of the upper die in the equipment of the present invention when it has been pressed in place. A method for bending metal pipes of the present invention includes the following steps:

[0028] (1) prepare a patrix 1, this patrix 1 comprises a fixed plate 11, a connector 12 and a die head 13, this die head 13 is fixed on the bottom of this fixed plate 11 by described connector 12, this die The lower surface of the head 13 is an arc-shaped curved surface 14 that transitions from the middle to the upper side of the two sides. On the lower surface of the die head 13, there is a second part extending to the side wall of the die head 13 for bending metal pipes. a groove 15;

[0029] (2) prepare lower mold 2, this lower mold 2 comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com