A kind of steel continuous processing equipment

A processing equipment and steel technology, applied in the field of continuous steel processing equipment, can solve problems such as the inability to realize angle steel discharge, and achieve the effects of simple structure, improved bending accuracy, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

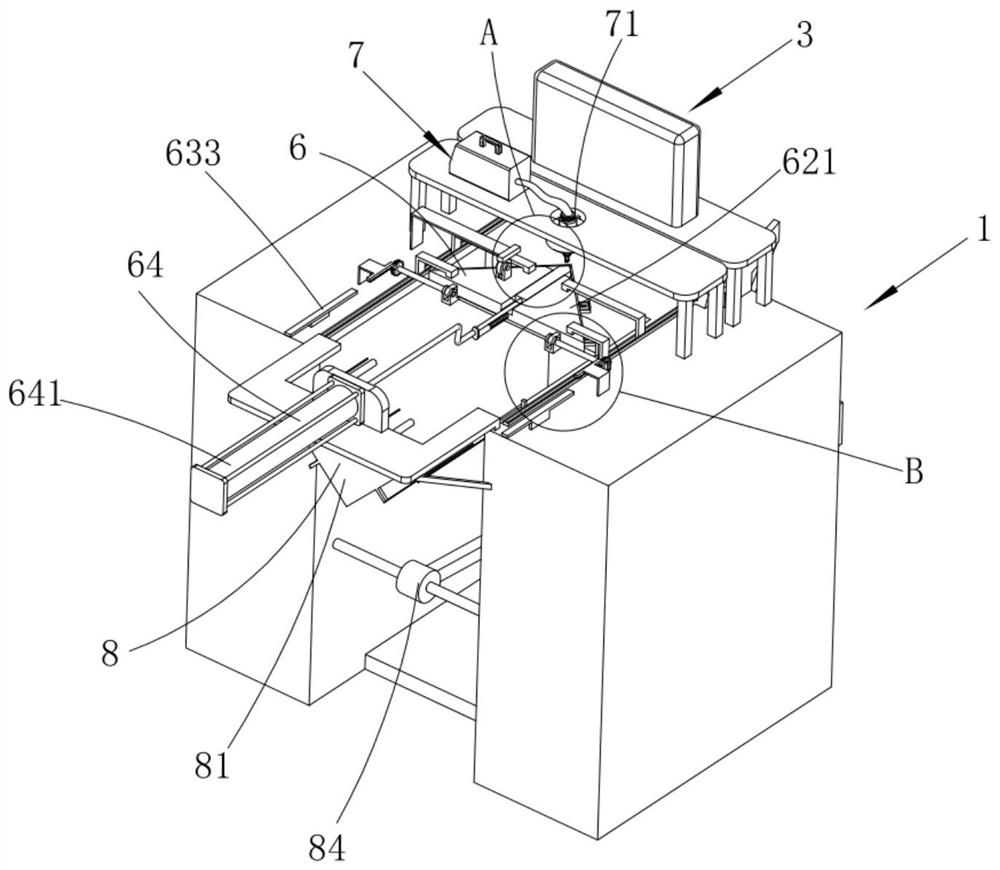

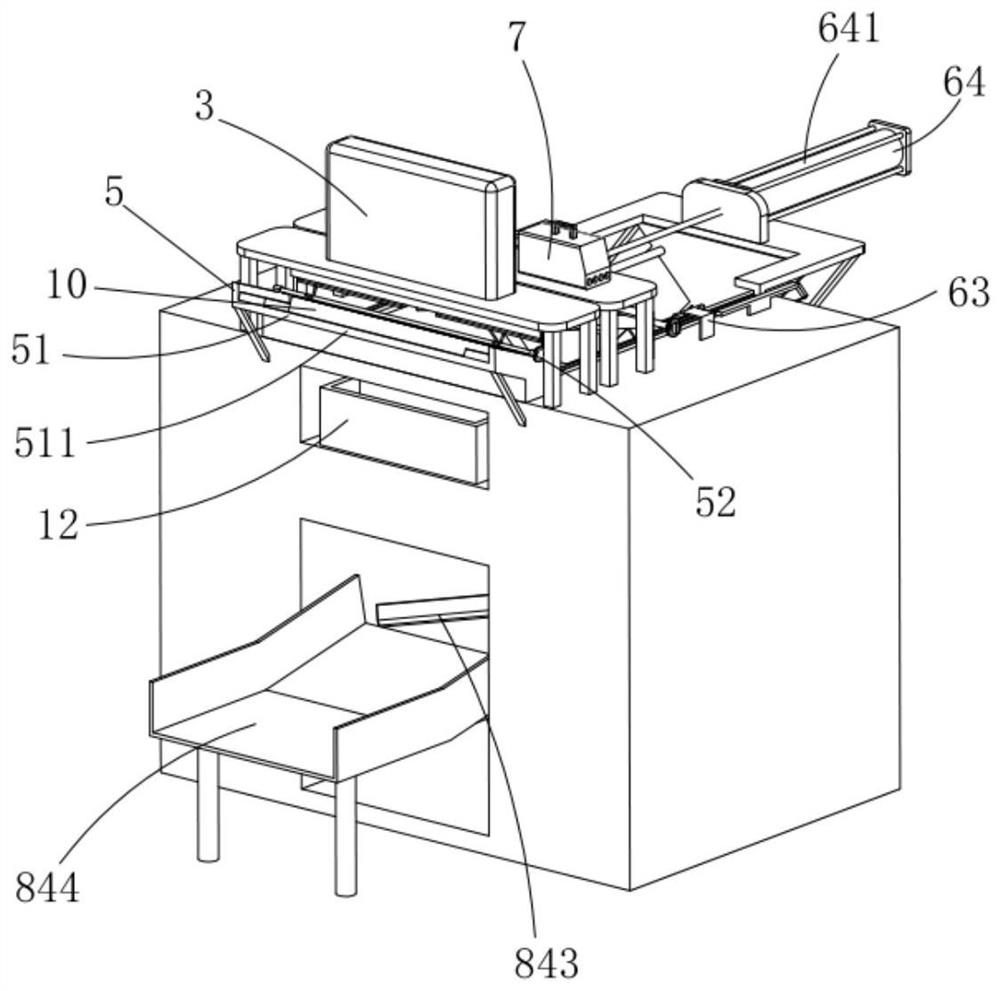

[0047] like figure 1 and figure 2 As shown, a continuous steel processing equipment includes a workbench 1, a lower die 2 mounted on the workbench 1, and an upper die 4 that is powered with a punching device 3 and faces the lower die 2. The lower die 2 The bottom is provided with a punch 21, and the bottom of the upper die 4 is provided with a punch 41 corresponding to the punch 21, and further includes:

[0048] A feeding device 5, the feeding device 5 includes a feeding assembly 51 arranged on one side of the lower die 2 and a control assembly 52 drivingly connecting the feeding assembly 51 and the upper die 4;

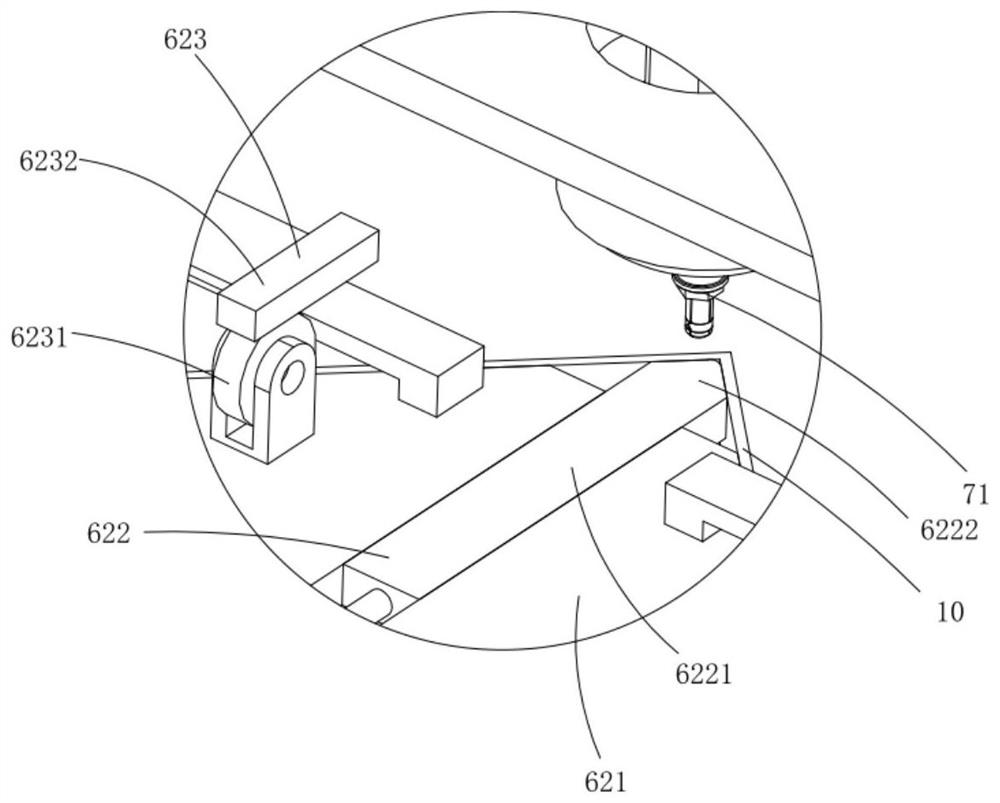

[0049] The bending device 6 includes a die base 61 that is transitionally connected to the lower die 2 and the material removal assembly 51 , and a die base 61 that is slidably arranged on the worktable 1 and matched with the die base 61 . a die assembly 62, a fastening component 63 rotatably mounted on the bottom of the die assembly 62, and a drive component 64 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com