Copper pipe bend forming device and method and bent pipe product

A technology for bending and forming copper tubes, applied in the mechanical field, can solve the problems of low efficiency, difficulty in affecting the accuracy of bending interfaces, and difficulty in ensuring the smoothness and accuracy of copper tube bending, so as to achieve convenient use and versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

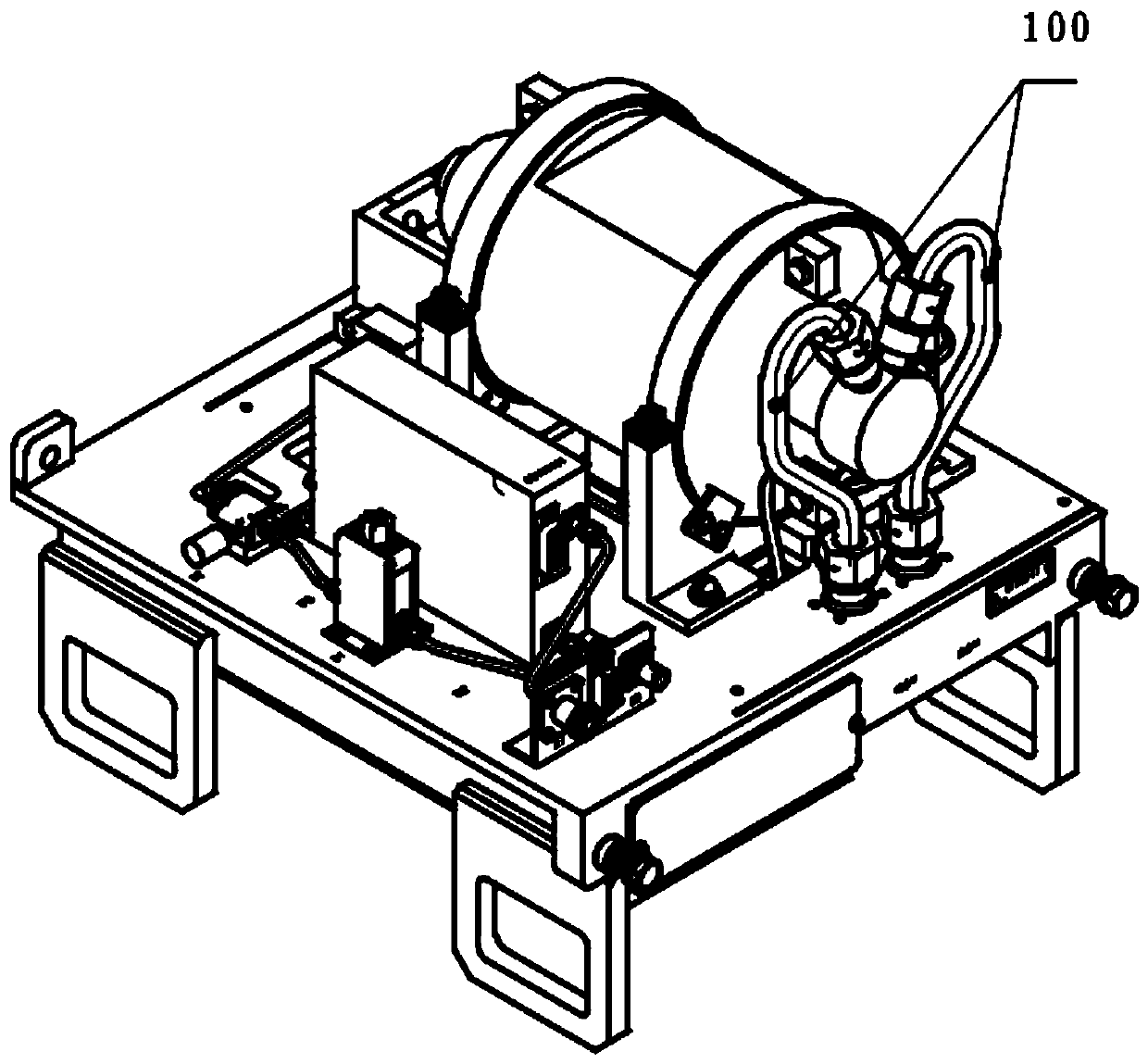

[0046] Such as Figure 4-6 Shown, a kind of copper tube bending forming device comprises:

[0047] base 1,

[0048] Chuck 2, bolt 4 Chuck 2 is installed on the bolt 4 base 1, the starting end of the copper pipe is clamped with the bolt 4 Chuck 2;

[0049] Several rollers 3 and several bolts 4 and rollers 3 are respectively installed on the bolt 4 base 1; the bolt 4 copper pipes are sequentially bent around several bolts 4 rollers 3 to form a product with several sections of bending;

[0050] Wherein, the installation position and shape of the bolt 4 chuck 2 and the bolt 4 roller 3 are set according to preset product parameters.

[0051]The base 1 is the installation basis of the chuck 2 and the roller 3, and at the same time serves as the bottom plane limit when the copper pipe is bent. After the chuck 2 and the roller 3 are installed on the base 1, when the copper pipe to be bent is bent, The base 1 is equivalent to the workbench, providing a stable foundation; when the ch...

Embodiment 2

[0061] A copper tube bending forming method, using the above-mentioned copper tube bending forming device, the steps include:

[0062] S1: According to the preset product parameters, select the corresponding chuck 2 and several rollers 3, and install the chuck 2 and several rollers 3 on the corresponding positions of the base 1;

[0063] S2: insert the starting end of the copper pipe into the bolt 4 clamp 2;

[0064] S3: Bending the copper pipe along each roller 3 .

[0065] After selecting the chuck 2 and roller 3 that match the preset product, install the chuck 2 and roller 3 at the corresponding position according to the preset product parameters. The starting end of the copper pipe fixed by the chuck 2 determines the starting position of the product. Then, the bending process is carried out along each roller 3 successively to obtain the bent pipe product 100 conforming to the preset. The present invention is applicable to the manual production of small batches of bent pip...

Embodiment 3

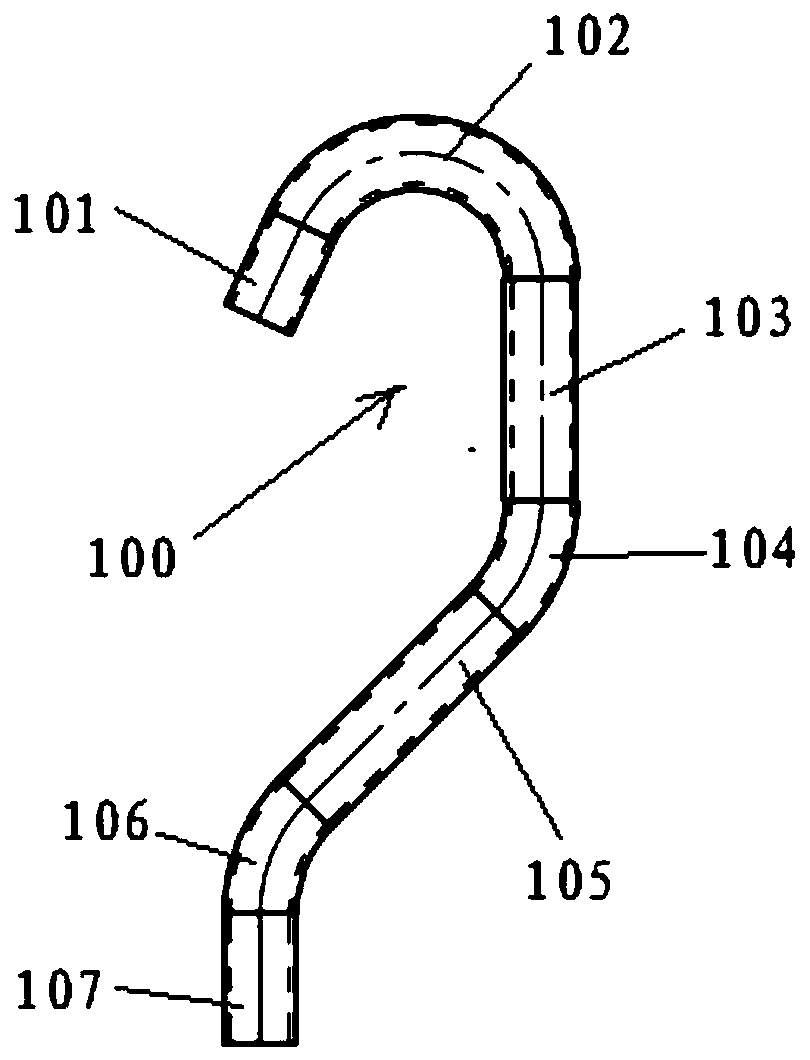

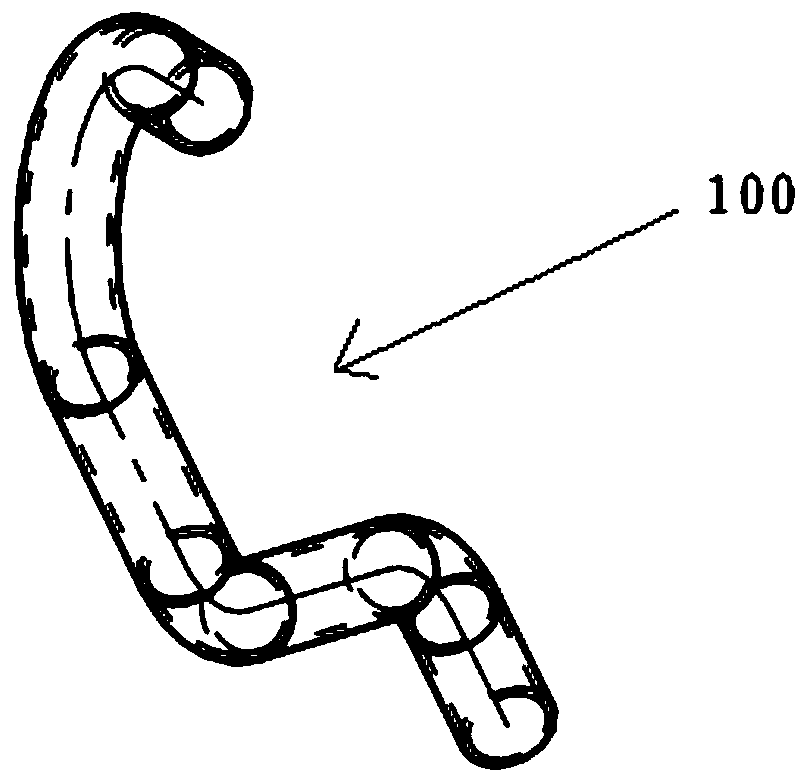

[0082] A bent pipe product 100 is formed by using the above copper pipe bending forming method.

[0083] Specifically, such as Figure 4 and 2 As shown, the bent pipe product 100 includes a first straight pipe section 101, a first bent pipe section 102, a second straight pipe section 103, a second bent pipe section 104, a third straight pipe section 105, and a third bent pipe section connected in sequence. 106 and the fourth straight pipe section 107.

[0084] The copper pipe bending and forming device includes a chuck 2 , a first roller 301 , a second roller 302 and a third roller 303 .

[0085] Select a reference coordinate axis to obtain the preset parameters of the product: the pipe diameter of the first straight pipe section 101, the inclination angle α of the starting end of the first straight pipe section relative to the reference axis, and the first straight pipe section 101 is selected. When the pipe diameter is suitable for the chuck 2, the chuck 2 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com