Laser weakening machining equipment

A kind of processing equipment and laser technology, which is applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of difficulty in grasping the production accuracy and dependence on control accuracy, and achieve the effects of improving accuracy, ensuring qualification, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

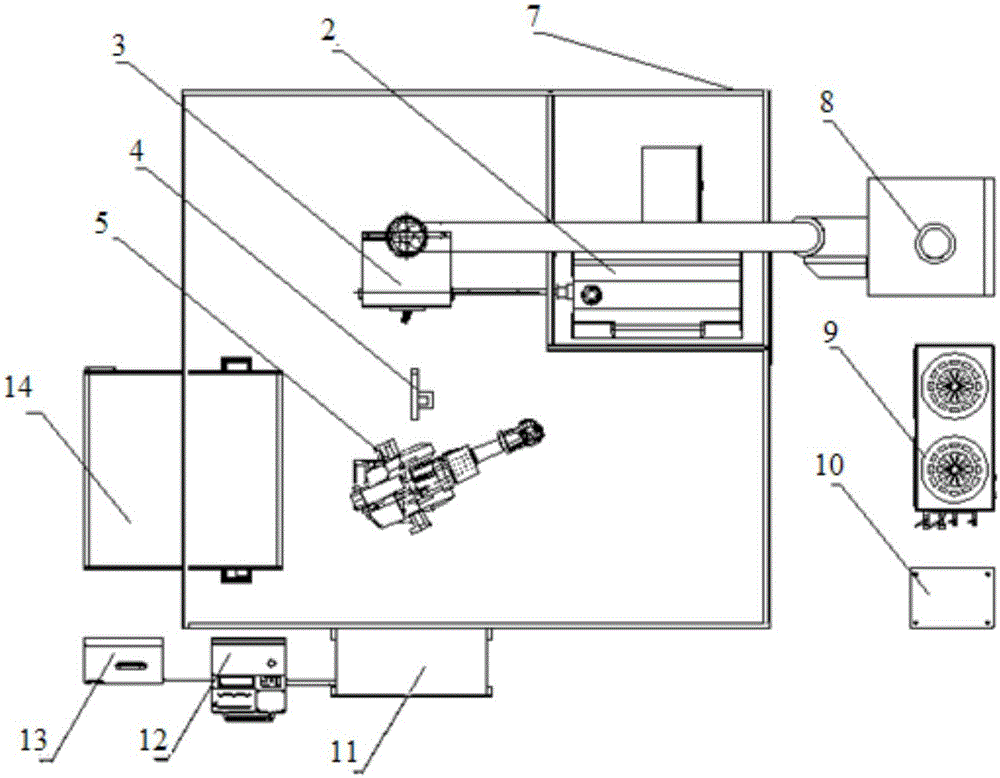

[0039] Embodiment 1 provided by the present invention is an embodiment of the overall equipment of a laser weakening processing equipment provided by the present invention, such as figure 2 Shown is a schematic diagram of the overall equipment structure of the laser weakening processing equipment provided by the embodiment of the present invention, which is represented by figure 2 It can be seen that the embodiment of the laser weakening processing equipment provided by the present invention also includes a supporting laser protection room 7, a dust collector 8, a chiller 9, a stabilized power supply 10, a feeding table 11, a main control cabinet 12, and a robot control cabinet 13 And unloading platform 14, realize equipment stability, environmental protection, safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com