Inclinable dual-pot wrapping device and process with multiple feed assemblies

A technology of multi-feeding and feeding devices, which is applied in the direction of drug delivery, capsule delivery, and pharmaceutical formulations. It can solve the problems of tablet surface coating peeling off, low production efficiency, and low degree of automation in discharging materials, so as to improve quality and save energy. The effect of production cost and enhanced convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

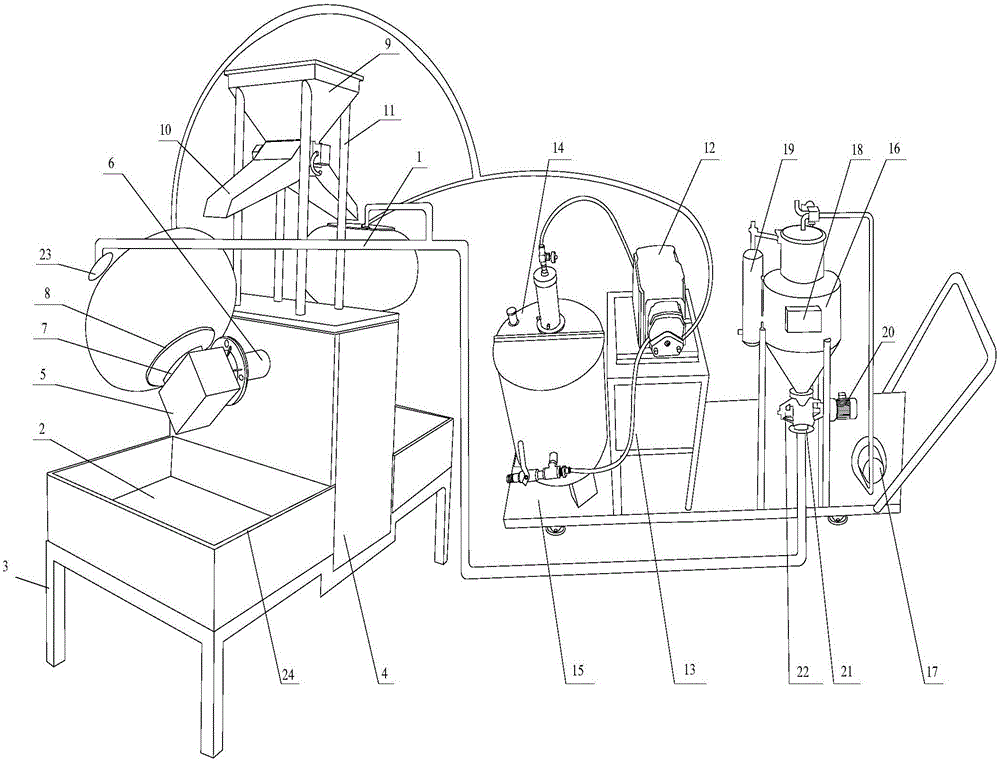

[0028] Below in conjunction with accompanying drawing, the present invention is further described:

[0029] A pourable double-pot coating device with a multi-feed assembly, including a powder feed assembly, a liquid feed assembly, a feeding device, a coating pot 1, a drive assembly, a hopper 2, and a bracket 3. The drive assembly includes a casing 4, a motor, and a reducer 5. Buttons are provided on the surface of the casing 4, a motor is provided inside, and two output shafts 6 are respectively provided on both sides of the outside. machine 5, the reducer 5 can move around the output shaft 6 in a semi-circle, the upper part of the reducer 5 is provided with a linkage shaft 7, and the linkage shaft 7 is connected with the coating pot 1 through a coupling plate 8, The coating pan 1 can move circularly around the linkage shaft 7, and the top of the housing 4 is provided with a feeding device, which includes a feeding hopper 9 and a distribution tank 10, and the upper part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com