High-precision sanding machine for furniture plates

A sanding machine, high-precision technology, used in manufacturing tools, belt grinders, grinding racks, etc., can solve the problem of affecting the sanding efficiency and reliability of plates, prone to stuck sanding, low sanding efficiency, etc. problems, to achieve the effect of ensuring qualification, ensuring flatness, and ensuring sanding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

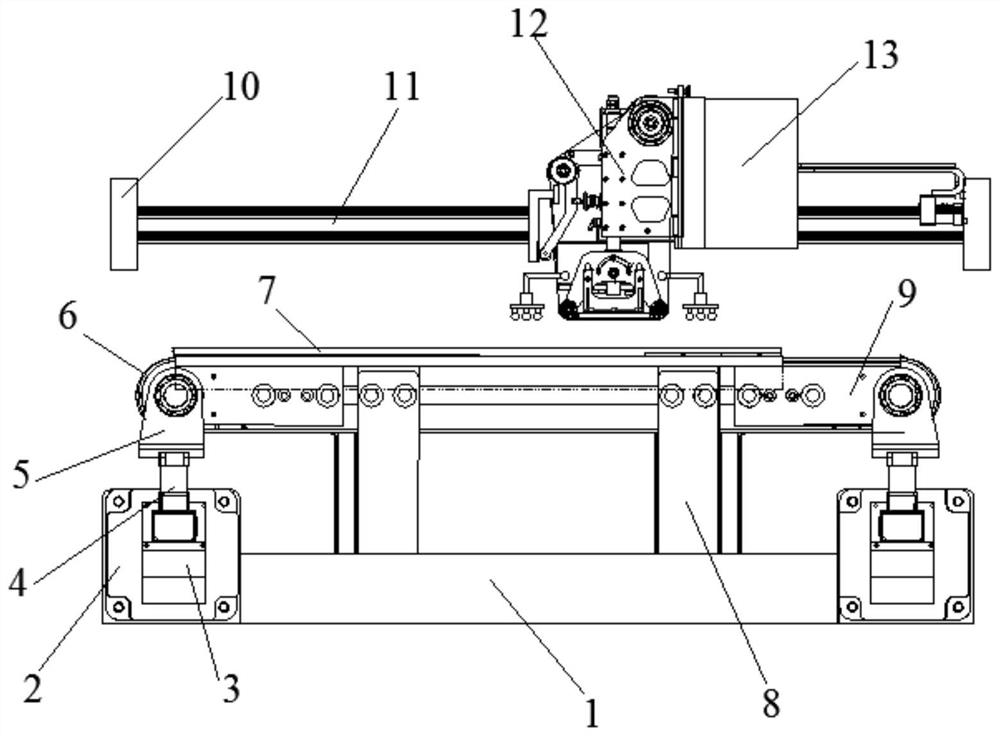

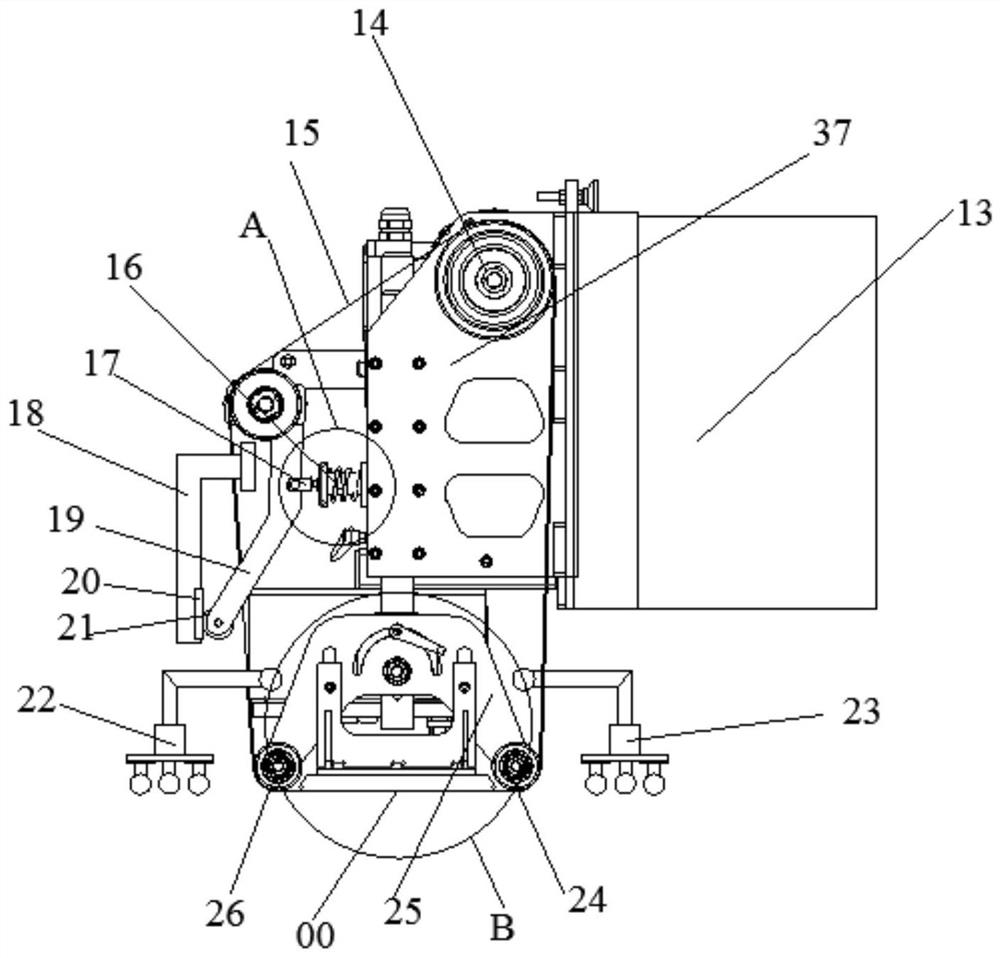

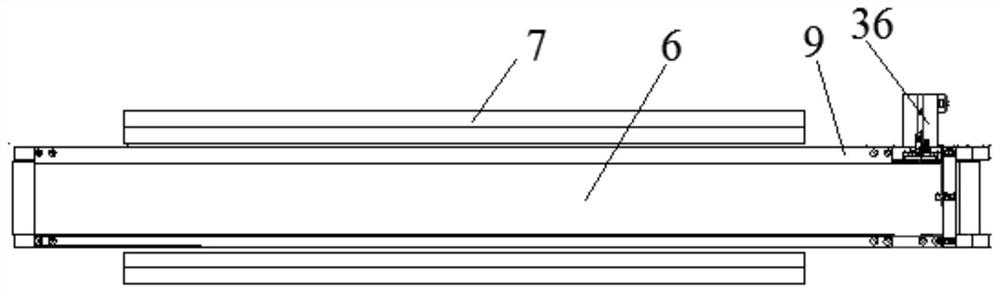

[0023] see Figure 1~6 , in an embodiment of the present invention, a sander for high-precision furniture boards, which includes a board conveying mechanism, a sanding support positioning platform 7, a lifting mechanism and a sander 12, wherein the two sides in the width direction of the board conveying mechanism The sanding support positioning platform 7 is arranged on the side, and the plate conveying mechanism is fixedly supported on the lifting mechanism, so as to drive the plate conveying mechanism up and down through the lifting mechanism, so that when the plate conveying mechanism rises, To realize the conveyance of the board, when the board conveying mechanism descends, the board can be supported and fixed on the sanding support positioning table for sanding, and the sander with an adjustable position is arranged above the sanding support table , characterized in that the sander 12 at least includes an abrasive belt 15, an abrasive belt winding assembly, an abrasive be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com