Integrated aerobic fermentation system with double-layer structure

A technology of aerobic fermentation and double-layer structure, which is applied in sludge treatment, biological sludge treatment, etc., can solve the problems of large floor area, low production efficiency, and low degree of automation, and achieve the reduction of equipment footprint, Use safe, reliable, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

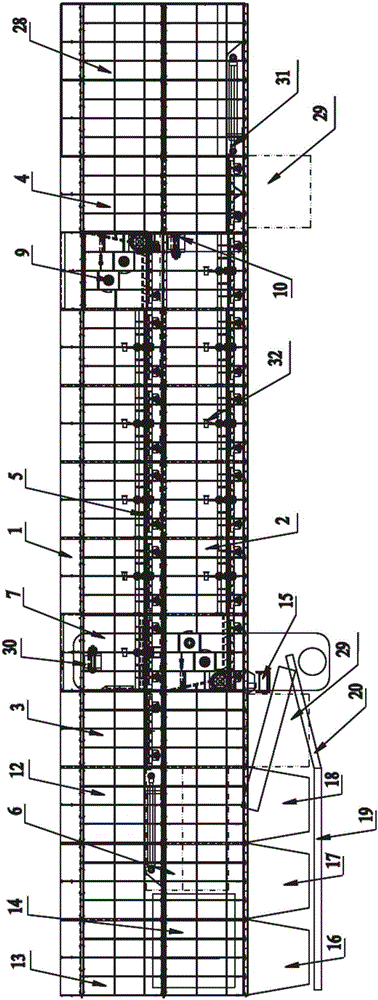

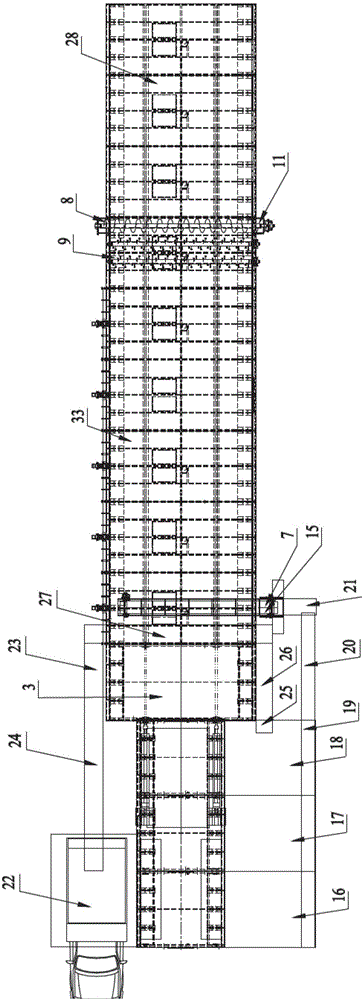

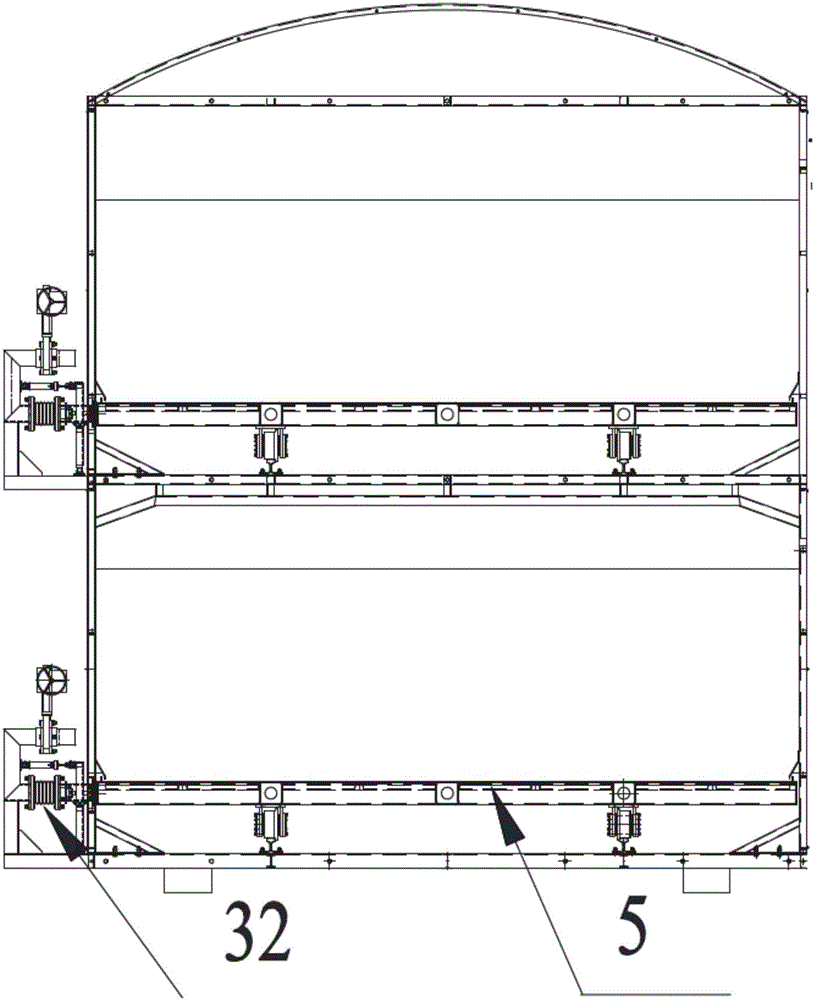

[0024] as attached figure 1 , 2, 3: the present invention is an integrated aerobic fermentation system of a double-layer structure, the system includes a primary fermentation chamber 1 and a secondary fermentation chamber 2 distributed in upper and lower layers, wherein the primary fermentation chamber 1 It is located on the upper floor, and the secondary fermentation 2 is located on the lower floor. On one side of the primary fermentation room 1 and the secondary fermentation room 2, there is an empty car lift room 3 connected up and down, and an empty car drop room 4 connected up and down. Empty car lifting chamber 3 and empty car falling chamber 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com