Three-needle-head-group type liquid filling and sealing machine

A filling and sealing machine and needle technology, applied in the field of three-needle group liquid filling and sealing machine, can solve the problems of polluting the surrounding environment of adjacent medicines, affecting the image of production enterprises, and increasing labor intensity, so as to improve the quality of production operations and reduce Packaging failure rate and the effect of reducing drug loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

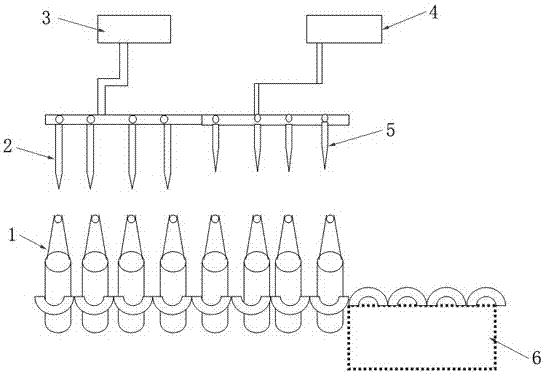

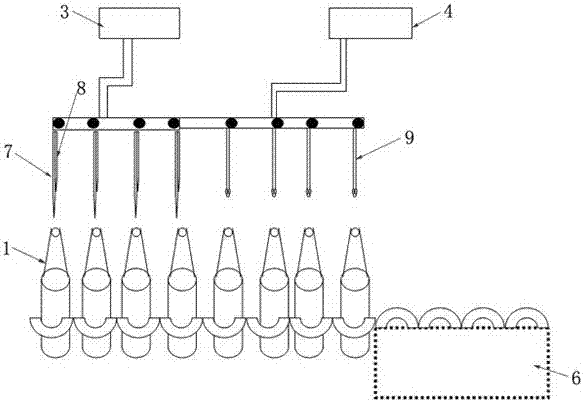

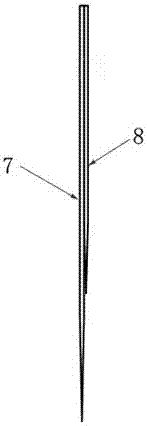

[0013] Such as figure 2 , image 3 , Figure 4 As shown, a three-needle group liquid filling and sealing machine includes a filling needle 7 and an inflation needle 9 fixed on the bracket, the liquid medicine 3 is connected to the filling needle 7 through a pipeline, and the gas storage tank 4 is connected to the inflation needle The needle 9 and the packaging bottle 1 are located on the conveyor chain below the filling needle and the inflation needle. The tail end of the conveyor chain is provided with a material tray 6, and a group of short suction needles 8 are arranged side by side at the filling needle 7; the inflation needle The bottom of the lower end of 9 is closed, and the lower end of the inflation needle 9 is evenly distributed with a plurality of transverse inflation holes 9a along the circumferential direction.

[0014] Further limitation of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com