System for detecting a partial or total obstruction of at least one internal pipe of a tool

A detection system and tool technology, applied in the field of detection systems, can solve problems such as inability to obtain measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

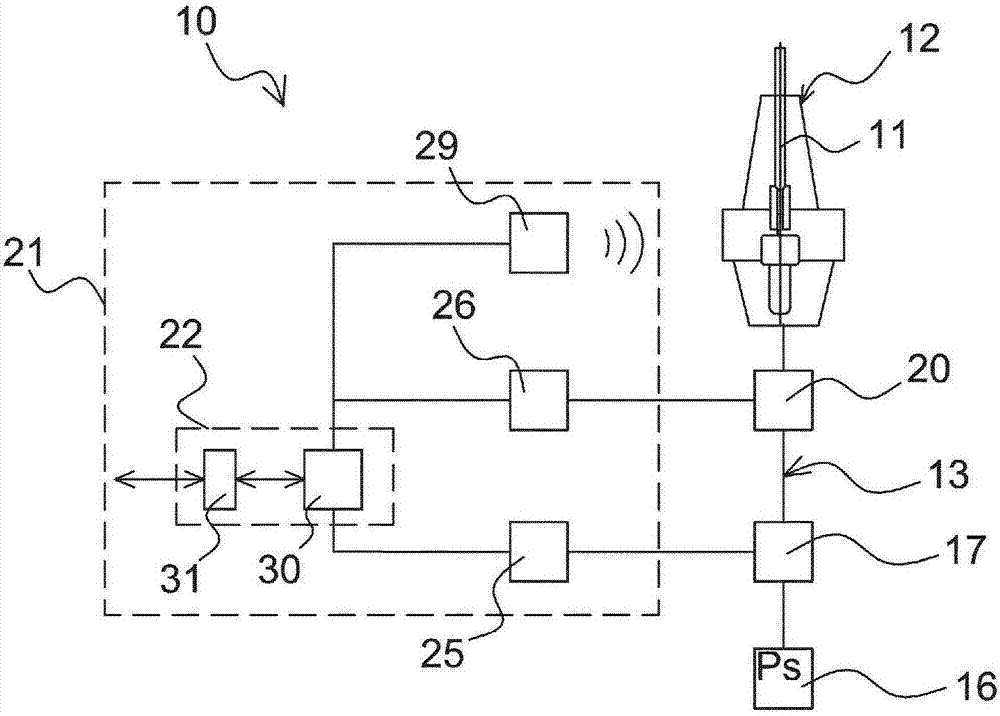

[0022] Identical, similar or analogous elements keep the same reference numerals in different figures.

[0023] figure 1 Shown is a detection system 10 for detecting a complete or partial blockage of at least one internal fluid conduit 11 of a tool 12, such as a machining tool. The one or more internal conduits 11 to be controlled can be used, for example, to supply the functional elements of the tool with a lubricating fluid, such as oil, an oily emulsion or a mist of air and oil. The system 10 may also be used to control a cryogenic processing tool 12 comprising at least one internal conduit 11 through which a cooling fluid, such as a nitrogen based cooling fluid, circulates.

[0024] Said system 10 is preferably used outside of machining operations carried out by the tool 12, that is to say the tool 12 is removed from the device to which it belongs for the first time, so that in said one or more internal pipes 11 Assembled on the system 10 at the end of the control. That...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com