Continuous-casting and continuous-coating production line for plate grid

A production line and continuous casting technology, used in foundry equipment, casting molding equipment, equipment for feeding molten metal into molds, etc. Improve the service life and ensure the effect of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

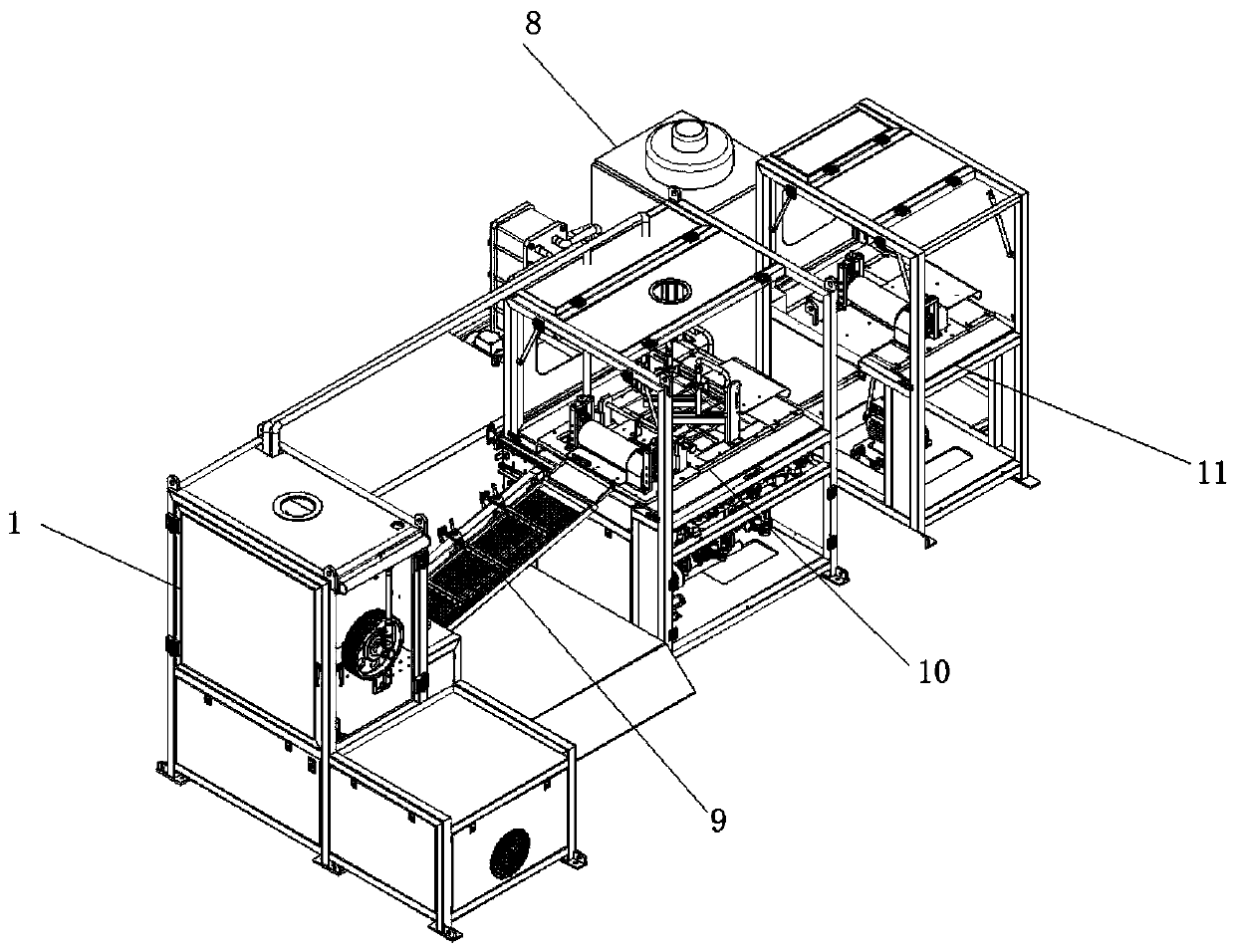

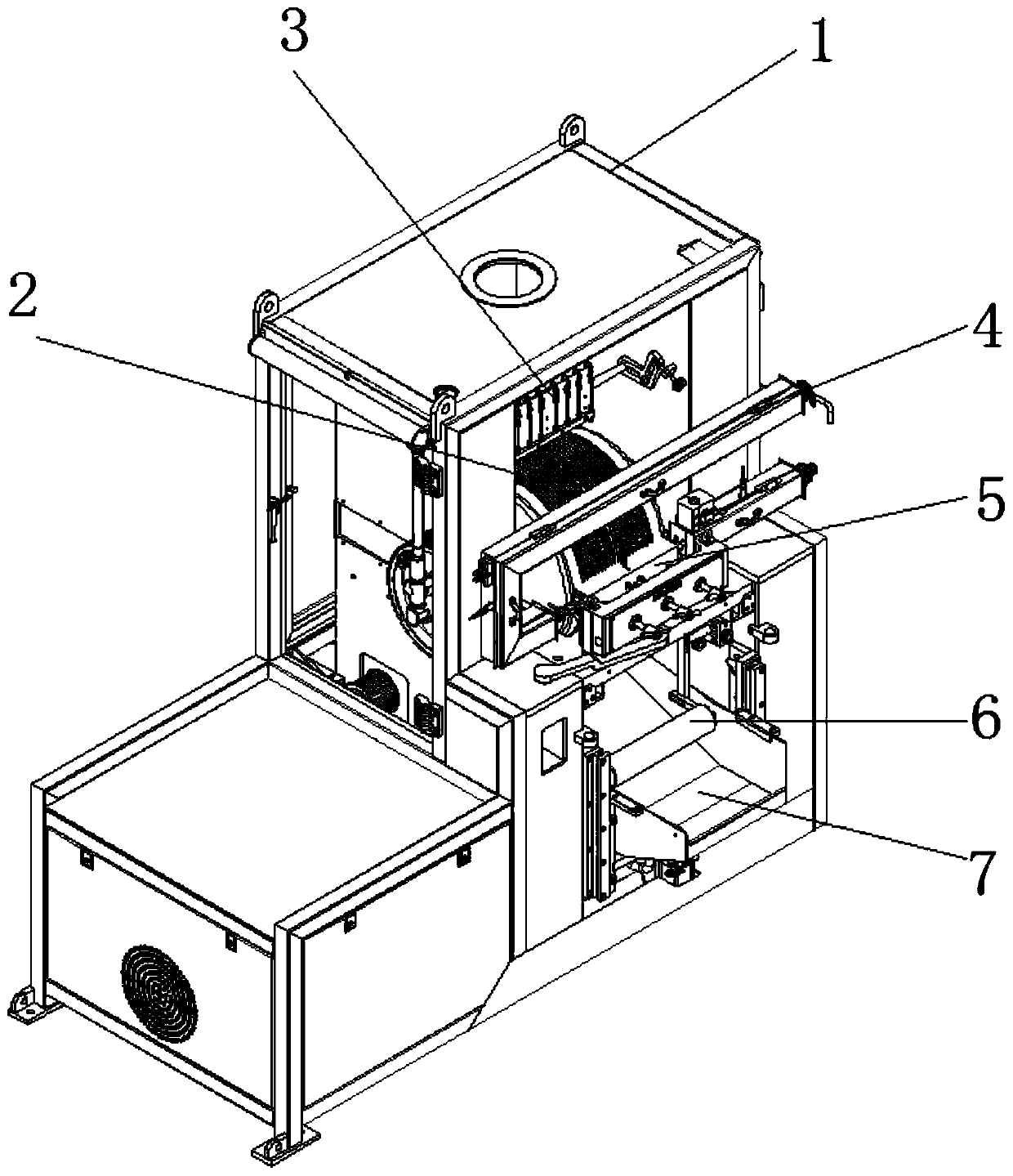

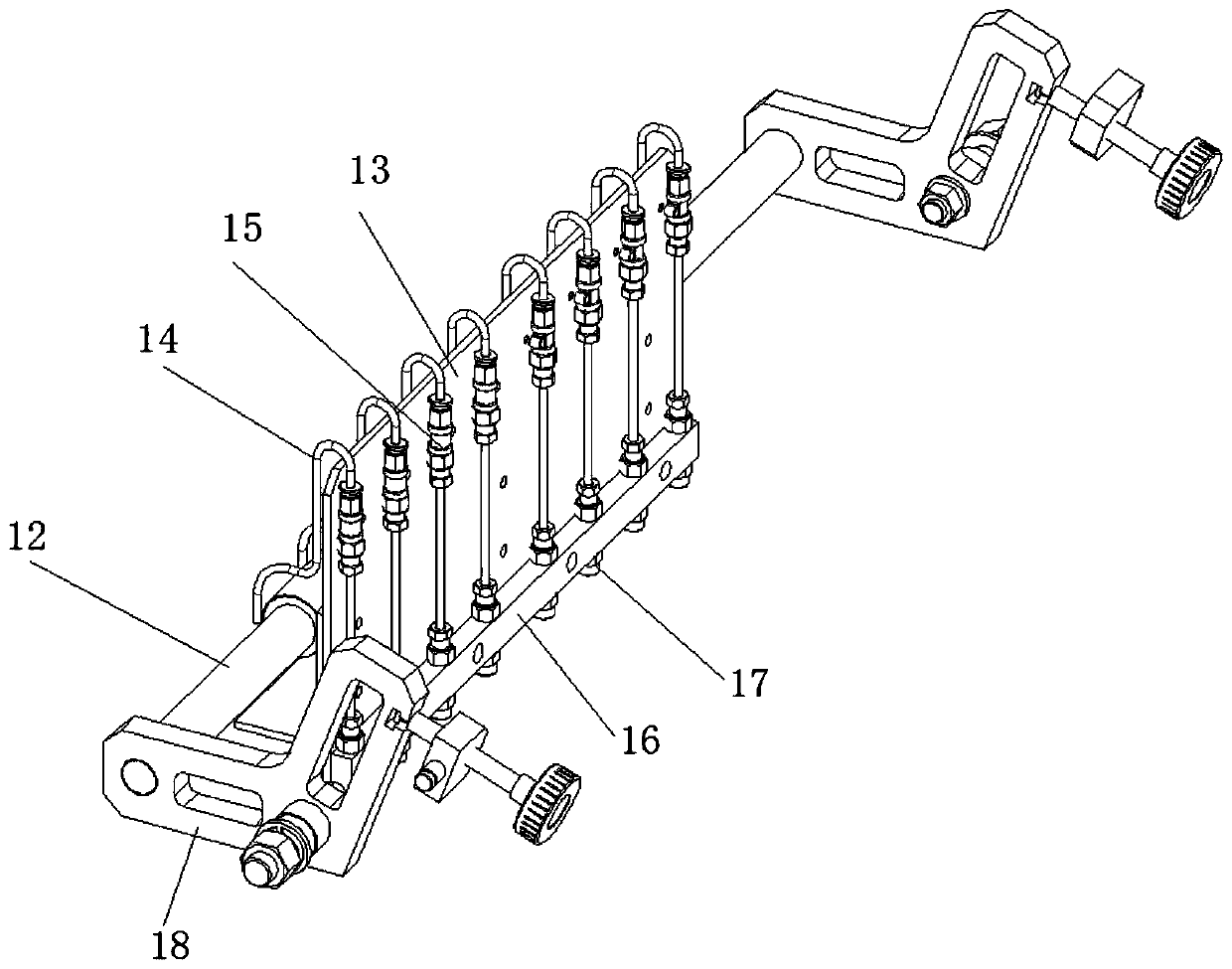

[0029] according to figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 11, the present embodiment provides a grid continuous casting and coating production line, including a frame 1, and the frame 1 is provided with a movable mold 2 , and the frame 1 above the movable mold 2 is provided with a demoulding oil spray assembly 3, one side of the frame 1 is provided with a lead delivery pipeline assembly 4, and the lead delivery pipeline assembly 4 is provided with the same The fixed mold 5 matched with the movable mold 2, the frame 1 on the outside of the fixed mold 5 is provided with a pressurizer, the inner side of the frame 1 is provided with a lead-out roller assembly 6, and the lead-out rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com