Electric-conductive heating glue and preparation method thereof

A technology of conductive heating glue and mixture, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc. It can solve the problems of uneven distribution, unsatisfactory, and tearing of carbon fibers and graphene, and avoid heat generation. Uniform, long service life, uniform heating effect

Inactive Publication Date: 2015-08-05

NANJING GREEN WOOD CO LTD

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

If the carbon fiber heating paper is applied to the floor, there are the following problems: 1) the papermaking process is likely to cause uneven distribution of carbon fibers and graphene in the paper; 2) additional adhesives are required, and the process is complicated; 4) Due to the poor ductility of the paper, it will be torn due to thermal expansion and contraction during use, which will easily generate arcs and pose a safety hazard

However, there are actually the following problems: 1) the process of coating or impregnating the conductive heat-generating paint on the substrate can easily cause the conductive heat-generating matrix material in the conductive heat-generating paint to be unevenly distributed on the surface of the substrate; 2) an additional adhesive is required , the process is complex; 3) The adhesive will penetrate into the conductive heating coating during the curing process, thereby affecting its conductive heating effect; 4) The conductive heating matrix material is easily oxidized on the surface of the substrate, which affects its service life; 5) The use of the substrate When using paper, due to its poor ductility, it will be torn due to thermal expansion and contraction during use, which will easily generate arcs and affect the safety of use

[0008] In short, the applicant has not found a conductive heating adhesive that can maintain uniform heating for a long time, ensure safe use, and has an adhesive effect from the prior art, and there is no corresponding manufacturing process that can ensure uniform distribution of substrates and simple and easy processes. Therefore, it cannot meet the needs of product development in many industries such as electric heating building materials, home appliances, equipment shields, and antifreeze equipment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0046] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Login to View More

Abstract

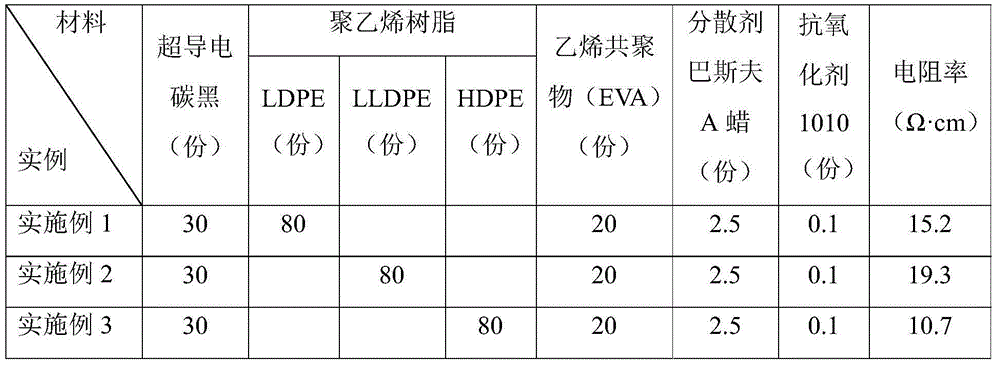

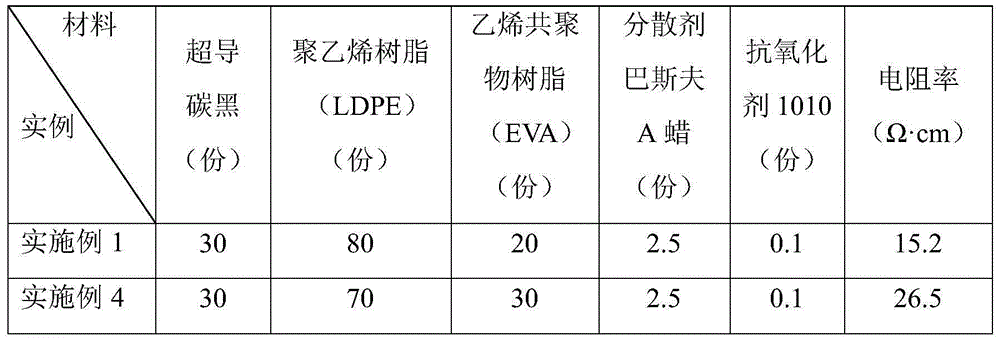

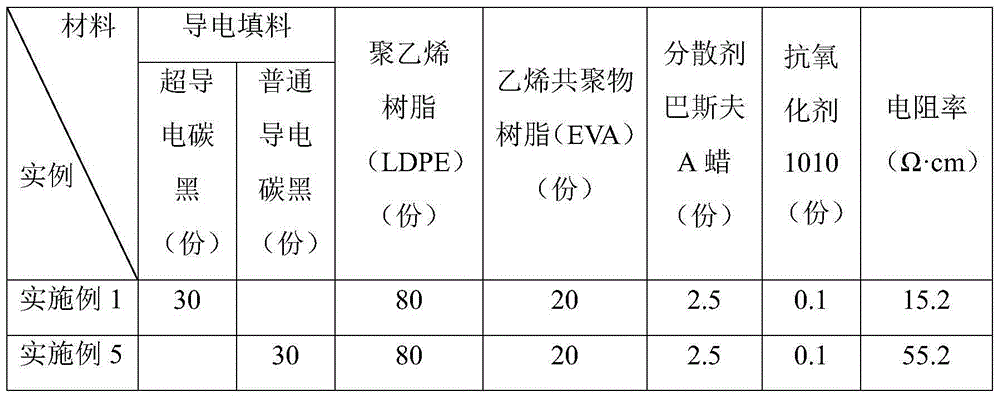

The invention relates to electric-conductive heating glue which includes following components, by mass: 15-45 parts of a electric-conductive heating filling material, 60-85 parts of polyethylene resin, 15-40 parts of ethylene copolymer resin, 1-5 parts of a dispersing agent and 0.1-2 parts of an anti-oxidizing agent. The electric-conductive heating glue not only is safe to use and can maintain uniform heating for long period, but also has a bonding effect. The invention also provides the preparation method of the electric-conductive heating glue. The electric-conductive heating glue can satisfy development requirements in the following fields: electric-heating building materials, household appliances, equipment shields, antifreezing devices and the like products.

Description

technical field [0001] The invention relates to a glue, especially a conductive heat-generating glue (including glue particles, glue films or glue powder); meanwhile, it also relates to its production process, which belongs to the technical field of electrothermal materials. Background technique [0002] Conductive heating materials mainly play the role of conductive heating in the field of conductive heating composite panels. With the improvement of people's living standards, the requirements for the comfort of the living environment are getting higher and higher. Heating equipment such as air conditioners and heaters cannot meet people's needs. Heating methods have been generally accepted by consumers. Because with the further improvement of environmental protection requirements, the traditional heating methods using oil, gas, and coal consume a lot of energy and produce a lot of pollutants, and the heat conversion efficiency is low. Therefore, low-energy and high-efficie...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J123/06C09J123/08C09J11/04

Inventor 杨晓辉

Owner NANJING GREEN WOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com