Activated humic acid formulated fertilizer special for sweet potatoes and preparation method of formulated fertilizer

A humic acid sweet potato and formula fertilizer technology, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of soil compaction, incomplete nutrition, damage to soil aggregate structure, etc., to improve the ecological environment, scientific and reasonable formula, reduce bad effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

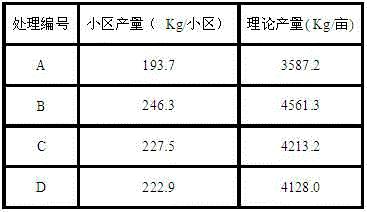

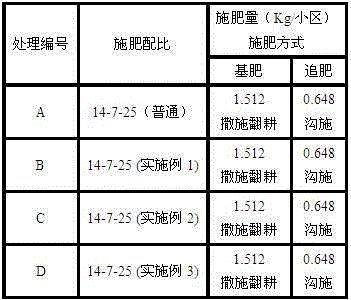

Examples

Embodiment 1

[0062] Sprayed humic urea liquid: 600 parts of urea, 100 parts of ammonium sulfate, 300 parts of humic acid, 50 parts of water.

[0063] Solid granulation raw materials: 230 parts of urea, 193 parts of industrial monoammonium phosphate, 480 parts of potassium sulfate, 30 parts of ammonium bicarbonate, 5 parts of anhydrous magnesium sulfate, 5 parts of boric acid, 4 parts of EDTA chelated zinc, 3 parts of EDTA chelated iron 2 parts, 2 parts of EDTA chelated manganese, 2 parts of EDTA chelated copper, 1 part of ammonium heptamolybdate.

[0064] Step 1: Melting urea. Open the steam valve of the main pipe, start the urea melting tank to stir, first add 50 kg of water to the urea-based tank, then add urea and ammonium sulfate in proportion, control the temperature of the urea-based tank at 115-125 ° C, after stirring completely melted, the urea liquid reaches overflow If there is liquid flowing out from the overflow pipe, stop dispensing urea.

[0065] Step 2: Prepare the saprope...

Embodiment 2

[0072] Sprayed humic urea liquid: 600 parts of urea, 100 parts of ammonium sulfate, 300 parts of humic acid, 50 parts of water.

[0073] Solid granulation raw materials: 230 parts of urea, 193 parts of industrial monoammonium phosphate, 480 parts of potassium sulfate, 30 parts of ammonium bicarbonate, 22 parts of bentonite.

[0074] Step 1: Melting urea. Open the steam valve of the main pipe, start the urea melting tank to stir, first add 50 kg of water to the urea-based tank, then add urea and ammonium sulfate in proportion, control the temperature of the urea-based tank at 115-125 ° C, after stirring completely melted, the urea liquid reaches overflow If there is liquid flowing out from the overflow pipe, stop dispensing urea.

[0075] Step 2: Prepare the sapropenic urea solution. When the liquid level in the urea melting tank reaches the position of the overflow pipe, stop batching. Turn on the heat preservation and steam valve of the reaction tank, turn on the stirring ...

Embodiment 3

[0082] 230 parts of urea, 193 parts of industrial monoammonium phosphate, 480 parts of potassium sulfate, 30 parts of ammonium bicarbonate, 5 parts of anhydrous magnesium sulfate, 5 parts of boric acid, 4 parts of EDTA chelated zinc, 3 parts of EDTA chelated iron, EDTA chelated Manganese 2 parts, EDTA chelated copper 2 parts, ammonium heptamolybdate 1 part, bentonite 55 parts.

[0083] Step 1: solid material urea, industrial monoammonium phosphate, potassium sulfate, ammonium bicarbonate, anhydrous magnesium sulfate, boric acid, EDTA chelated zinc, EDTA chelated iron, EDTA chelated manganese, EDTA chelated copper, ammonium heptamolybdate , The bentonite is put into the drum granulator according to the proportion for granulation.

[0084] Step 2: drying, cooling and sieving. The material is preliminarily granulated in the granulator, and then passed through the primary drying drum---the primary cooling drum---screening---the secondary drying drum---the secondary cooling drum--...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com