Preparation method of heteromorphic microporous ceramic capillary

A technology of microporous ceramics and capillary tubes, applied in ceramic molding machines, manufacturing tools, coupling of optical waveguides, etc., can solve the problems of poor powder fluidity, poor mixing uniformity, high softening temperature, etc., and achieve ultra-fine powder, shape The effect of regular appearance and high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

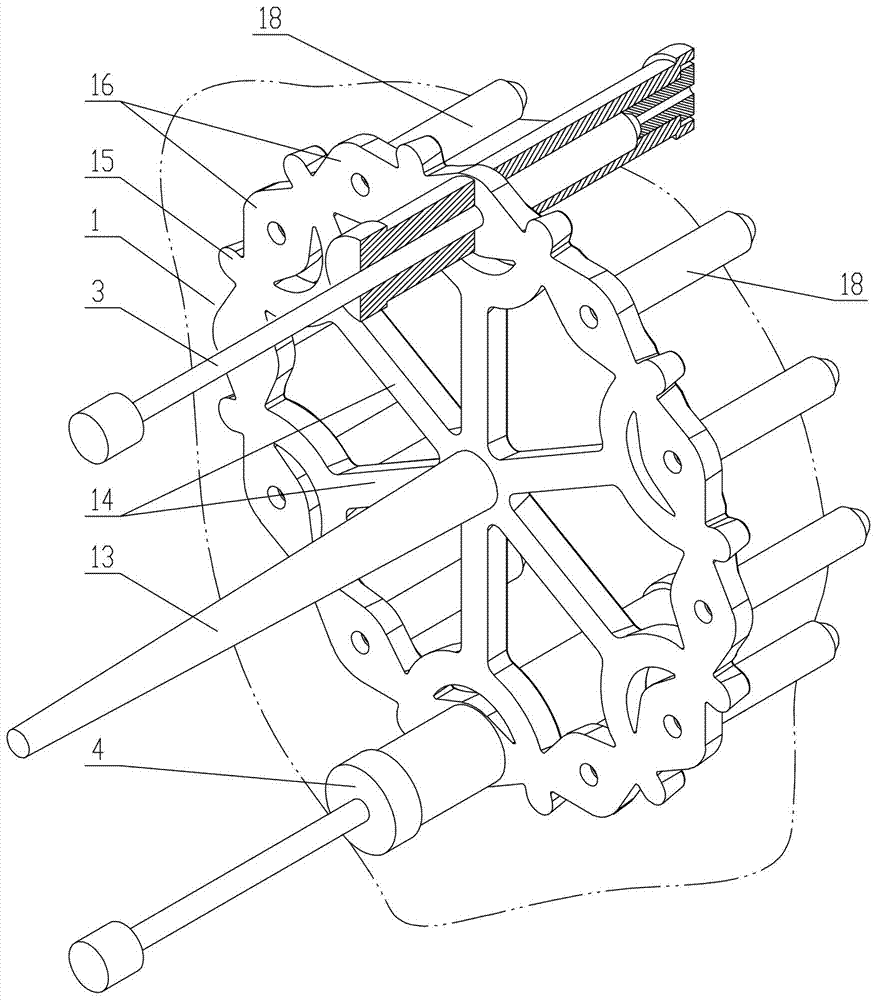

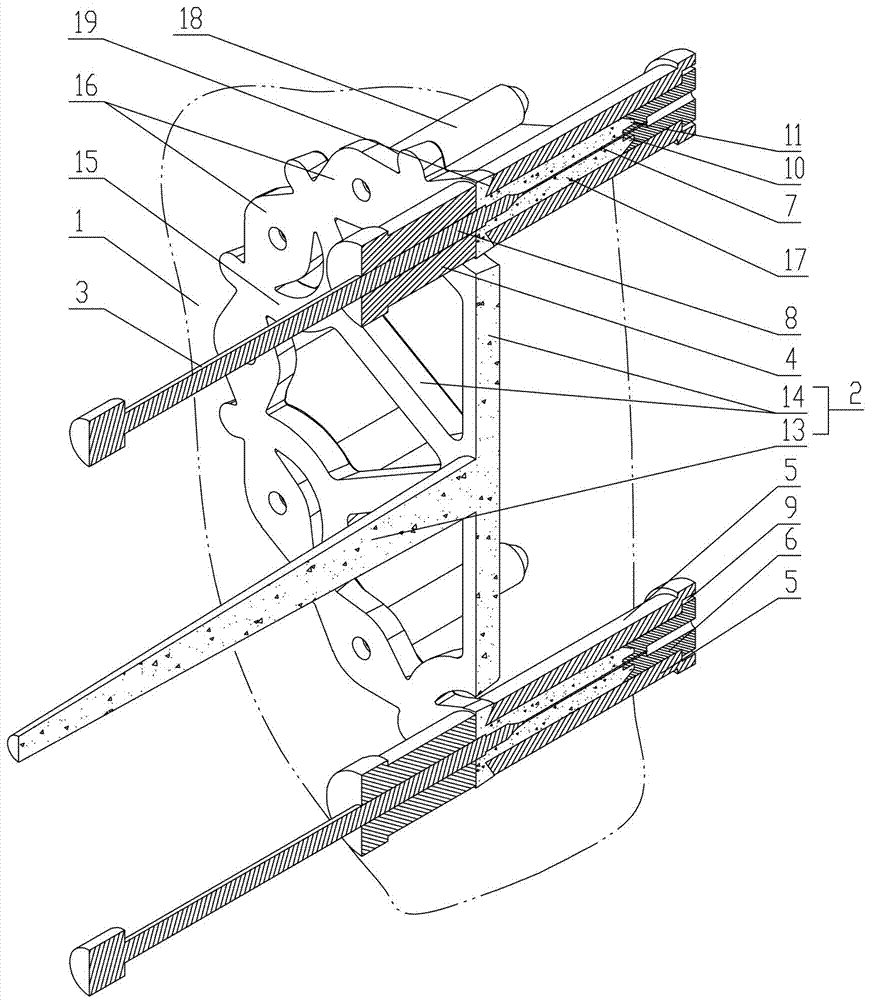

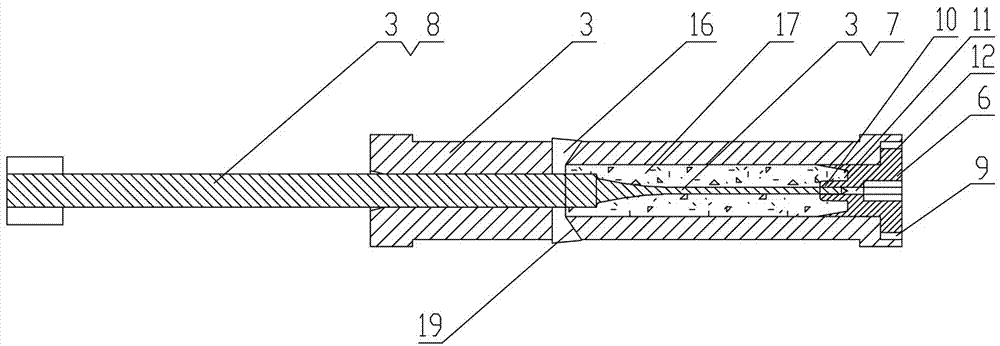

[0039] see Image 6 , Figure 7 , this embodiment takes the preparation of a double-core ceramic capillary as an example to further explain the preparation method of the present invention.

[0040] see Figure 1-Figure 7 , a preparation method of special-shaped microporous ceramic capillary, comprising the steps of:

[0041] (1) Preparation of zirconia particles: Take 82 parts by weight of yttrium-stabilized nano-zirconia powder, dry it at 135°C for 4 hours, put it into a mixer, and put 9 parts by weight of thermoplastic acrylic resin at the same time, stir evenly, and preheat to 150°C , then add 3.5 parts by weight of modified polystyrene, 1.5 parts by weight of stearic acid, and 4 parts by weight of paraffin, and stir for about 35 minutes to form a slurry, and continue mixing for 2 hours at 175 ° C until the zirconia powder and various The organic matter is completely mixed evenly, and then scraped out and enters the granulator for granulation to obtain zirconia ceramic p...

Embodiment 2

[0054] see Figure 8 , Figure 9 , this embodiment takes the preparation of a four-core ceramic capillary as an example to further explain the preparation method of the present invention.

[0055] A method for preparing a special-shaped microporous ceramic capillary, comprising the steps of:

[0056] (1) Preparation of zirconia particles: Take 81 parts by weight of yttrium-stabilized nano-zirconia powder, dry it at 150°C for 3 hours, put it into a mixer, and put 10 parts by weight of thermoplastic acrylic resin at the same time, stir evenly, and preheat to 150°C , then add 4 parts by weight of modified polystyrene, 2 parts by weight of stearic acid, and 3 parts by weight of paraffin wax, and stir for about 30 minutes to form a slurry, and continue mixing for 2 hours at 170 ° C until the zirconia powder is mixed with various The organic matter is completely mixed evenly, and then scraped out and enters the granulator for granulation to obtain zirconia ceramic particles with a d...

Embodiment 3

[0066] This embodiment takes the preparation of a 16-core ceramic capillary as an example to further explain the preparation method of the present invention.

[0067] A method for preparing a special-shaped microporous ceramic capillary, comprising the steps of:

[0068] (1) Preparation of zirconia particles: Take 83 parts by weight of yttrium-stabilized nano-zirconia powder, dry it at 120°C for 5 hours, put it into a mixer, and put 8 parts by weight of thermoplastic acrylic resin at the same time, stir evenly, and preheat to 150°C , then add 3 parts by weight of modified polystyrene, 1 part by weight of stearic acid, and 5 parts by weight of paraffin wax, and stir for about 40 minutes to form a muddy state, and continue mixing for 2 hours at 180 ° C until the zirconia powder is mixed with various The organic matter is completely mixed evenly, and then scraped out and enters the granulator for granulation to obtain zirconia ceramic particles with a diameter of 3-4mm and a leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com