Composite non-woven fabric ceramic diaphragm for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and ceramic diaphragms, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of poor heat resistance, easy water absorption, and easy falling off of the diaphragm, achieve good wetting characteristics, and increase high temperature resistance The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

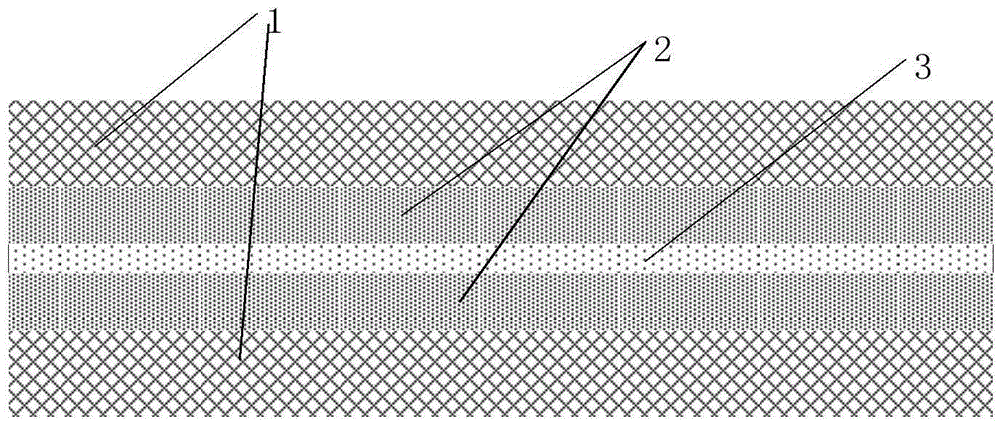

[0033] At room temperature, add 1.5 g of sodium carboxymethylcellulose (CMC) and 0.1 g of styrene-butadiene rubber (SBR) into 100 mL of deionized water, stir at 60°C for 1 hour, and then continue to stir at room temperature for 8 hours. It is fully dissolved to form a colorless and transparent glue. Add 2g of aluminum oxide powder with a particle size of 40nm to the glue solution and stir for 8 hours to fully disperse it in the sol to form an organic-inorganic mixture. Then the mixture is uniformly coated on one side of the polyethylene non-woven membrane by a coating machine with a thickness of 4 μm. With the coated side facing up, another non-woven membrane of the same specification is quickly pressed on the coated surface to make two The non-woven fabric separators are tightly attached together, then dried at 110°C, and finally rolled to form the non-woven fabric ceramic composite separator A1 with a sandwich structure.

Embodiment 2

[0035] At room temperature, add 4g of polyvinylidene fluoride (PVDF) into 100mL of deionized water, stir at 60°C for 1 hour, and then continue to stir at room temperature for 8 hours to fully dissolve it to form a colorless and transparent glue. Add 2g of Al2O3 powder with a particle size of 1 μm to the glue solution, stir for 8 hours to fully disperse it in the sol to form an organic-inorganic mixture. Then the mixture is uniformly coated on one side of the polyethylene non-woven membrane by a coating machine with a thickness of 4 μm. With the coated side facing up, another non-woven membrane of the same specification is quickly pressed on the coated surface to make two The non-woven fabric separators are tightly bonded together, then dried at 110°C, and finally rolled to form a sandwich-structured non-woven ceramic composite separator A2.

Embodiment 3

[0037]At room temperature, add 2g of carboxymethylcellulose sodium (CMC) into 100mL of deionized water, stir at 60°C for 1 hour, and then continue to stir at room temperature for 8 hours to fully dissolve it to form a colorless and transparent glue . Add 3g of silicon dioxide powder with a particle size of 200nm to the glue, and stir for 8 hours to fully disperse it in the sol to form an organic-inorganic mixture. Then the mixture is uniformly coated on one side of the polyamide non-woven fabric diaphragm by a coating machine, with a thickness of 6 μm. With the coated side facing up, quickly press another non-woven fabric diaphragm of the same specification on the coated surface, so that the two sheets The non-woven fabric separators are tightly attached together, then dried at 110°C, and finally rolled to form a sandwich-structured non-woven ceramic composite separator A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com