Coating type wave-absorbing aramid paper, wave-absorbing honeycomb and preparation method

A kind of aramid paper, coating type technology, applied in special paper, coating, paper and other directions, can solve the problems of reduced resin permeability, poor mechanical properties of honeycomb, easy shrinkage deformation, etc., to improve electromagnetic loss capacity, improve absorption effect of agent content, high electromagnetic loss capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

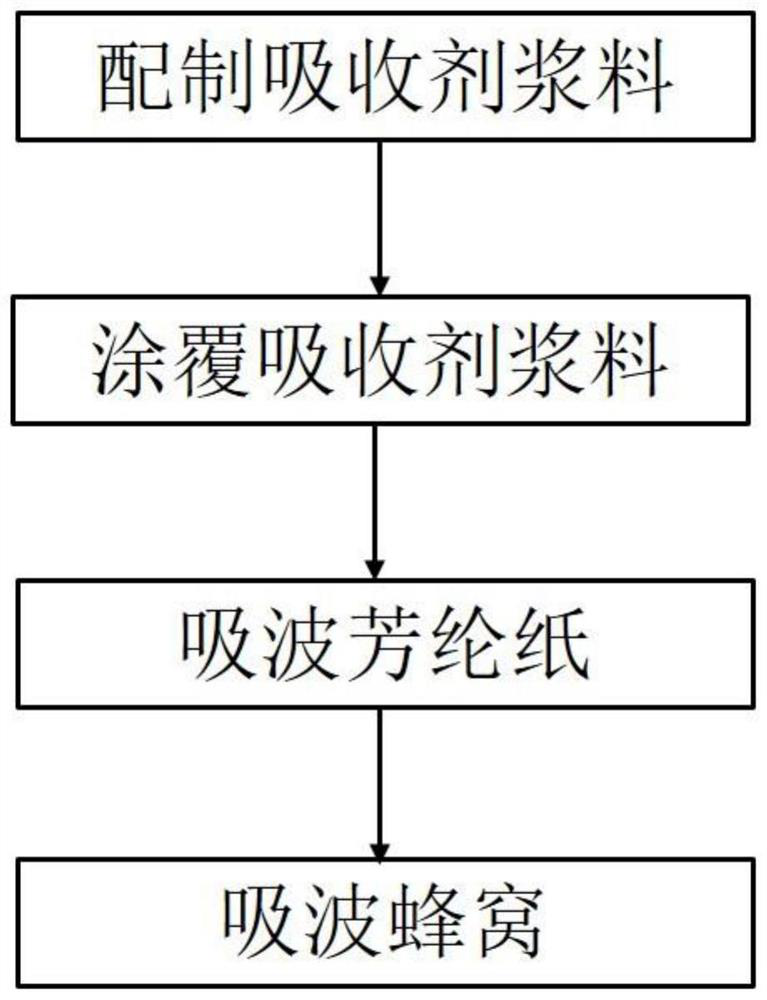

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, carbon black is selected as the absorbent, phenolic resin is used as the adhesive, and the volume ratio of carbon black to resin is 1:2. The absorbent slurry is coated on the surface of the aramid paper by spraying, and after drying and curing Obtain the wave-absorbing aramid paper, the thickness of the wave-absorbing layer is 0.02mm, and the quantitative of the wave-absorbing aramid paper is 60g / m 2 , with a thickness of 60 μm.

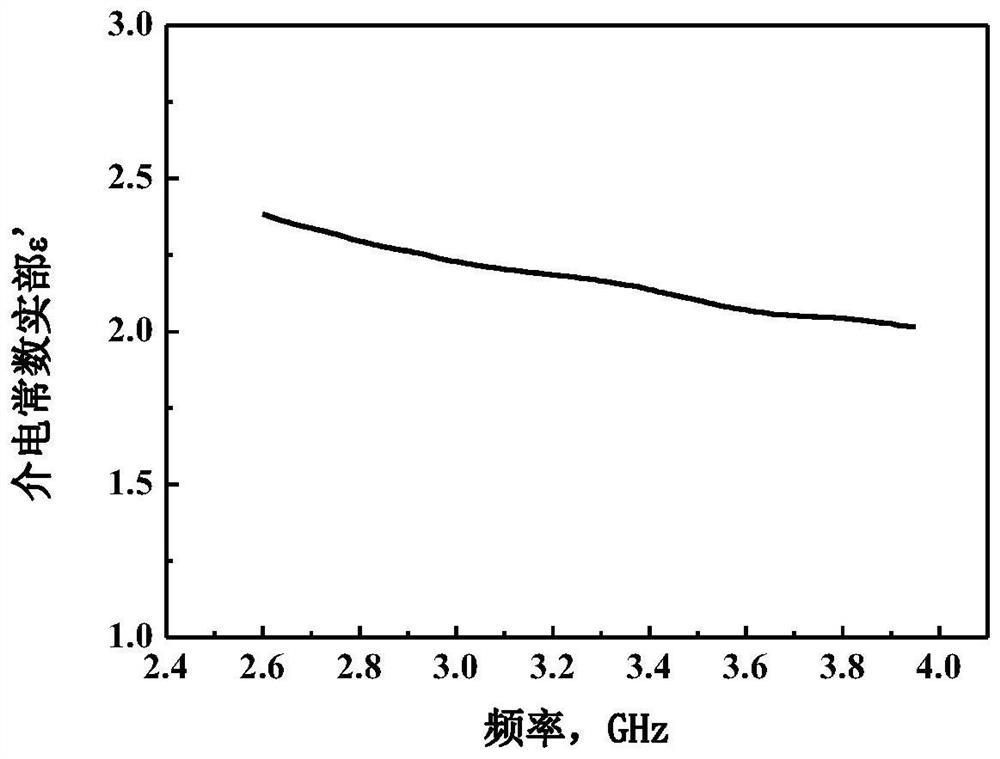

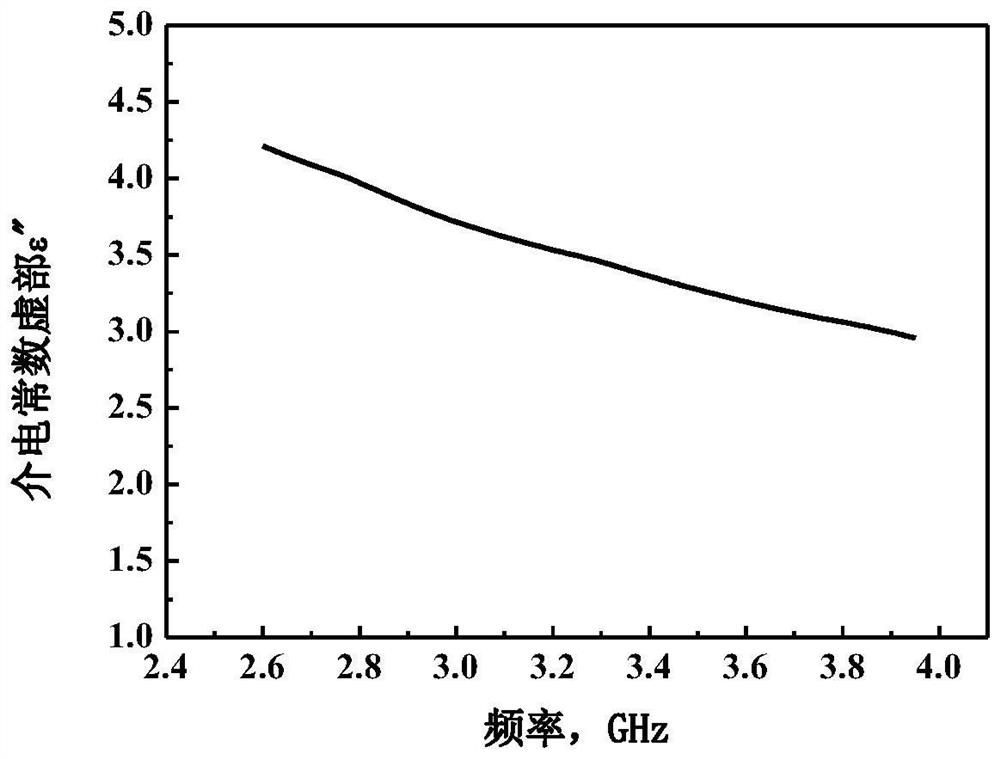

[0029] The prepared wave-absorbing aramid paper is passed through adhesive core strips, lamination, hot pressing, stretching, dipping, drying, and curing processes, according to the cell side length of 1.83mm and density of 55kg / m 3 Controlling the process, the wave-absorbing honeycomb was produced, and the flat compressive strength test was carried out on it, and the result was 2.29MPa. The electromagnetic parameter test (real part of dielectric constant, imaginary part of dielectric constant) in the frequency band of 2.6G...

Embodiment 2

[0031] The difference from Example 1 is that carbon fiber is selected as the absorbent, the volume ratio of the resin to the resin is 1:1, the thickness of the wave-absorbing layer is 0.05mm, and the rest of the process is the same as that of Example 1.

[0032]The prepared wave-absorbing aramid paper is passed through adhesive core strips, lamination, hot pressing, stretching, dipping, drying, and curing processes, according to the cell side length of 1.83mm and density of 65kg / m 3 Controlling the process, the wave-absorbing honeycomb was prepared, and the flat compressive strength test was carried out on it, and the result was 2.63MPa. The electromagnetic parameter test (real part of dielectric constant, imaginary part of dielectric constant) in the frequency band of 2.6GHz to 3.95GHz was carried out on it, and the result was Such as Figure 3A , Figure 3B shown. The real part of the dielectric constant of the wave-absorbing honeycomb is 3.2-4.2, the imaginary part of the...

Embodiment 3

[0034] In this embodiment, carbon fiber and iron powder are selected as the absorbent, and Shuangma resin is used as the adhesive. The volume ratio of carbon fiber, carbonyl iron powder and resin is 1:1:10. The absorbent slurry is coated with aromatic The surface of the fiber paper is dried and cured to obtain wave-absorbing aramid paper, the thickness of the wave-absorbing layer is 0.1mm, and the weight of the wave-absorbing aramid paper is 80g / m 2 , with a thickness of 65 μm.

[0035] The prepared wave-absorbing aramid paper is passed through adhesive core strips, lamination, hot pressing, stretching, dipping, drying, and curing processes, according to the cell side length of 2.77mm and density of 75kg / m 3 Controlling the process, the wave-absorbing honeycomb was prepared, and the flat compressive strength test was carried out on it, and the result was 3.29MPa. The electromagnetic parameter test (real part of dielectric constant, imaginary part of dielectric constant) in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com