Patents

Literature

35results about How to "Wide range of application requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

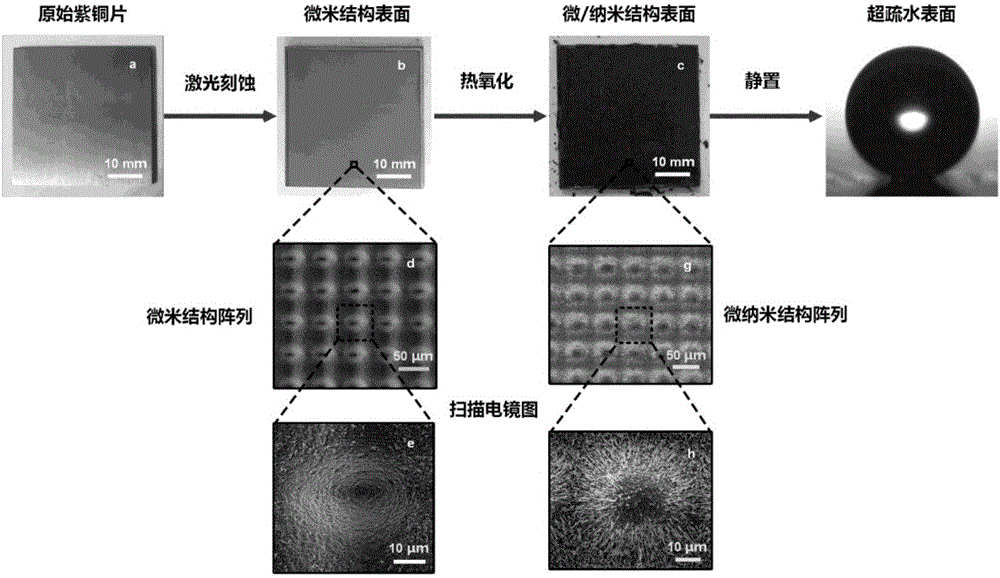

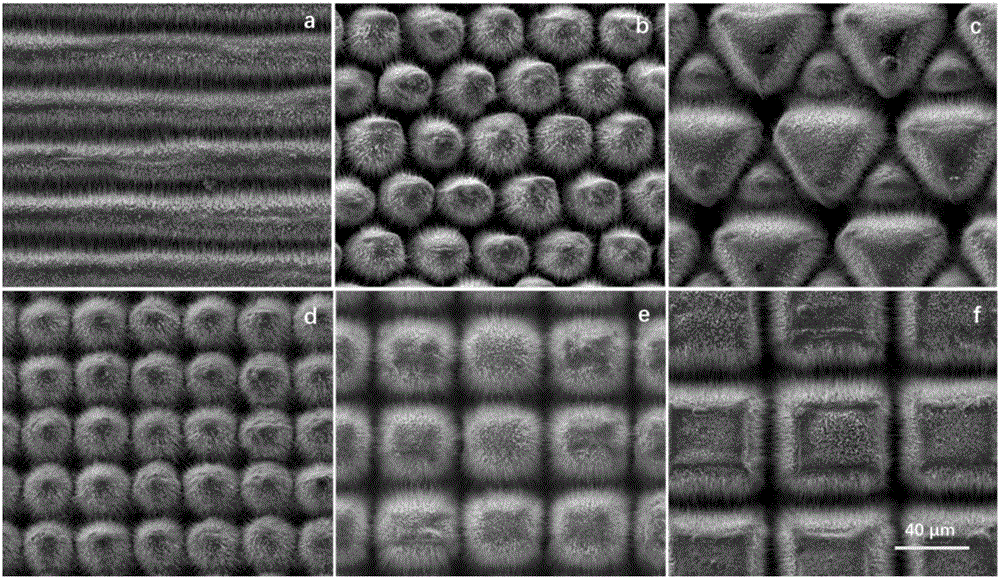

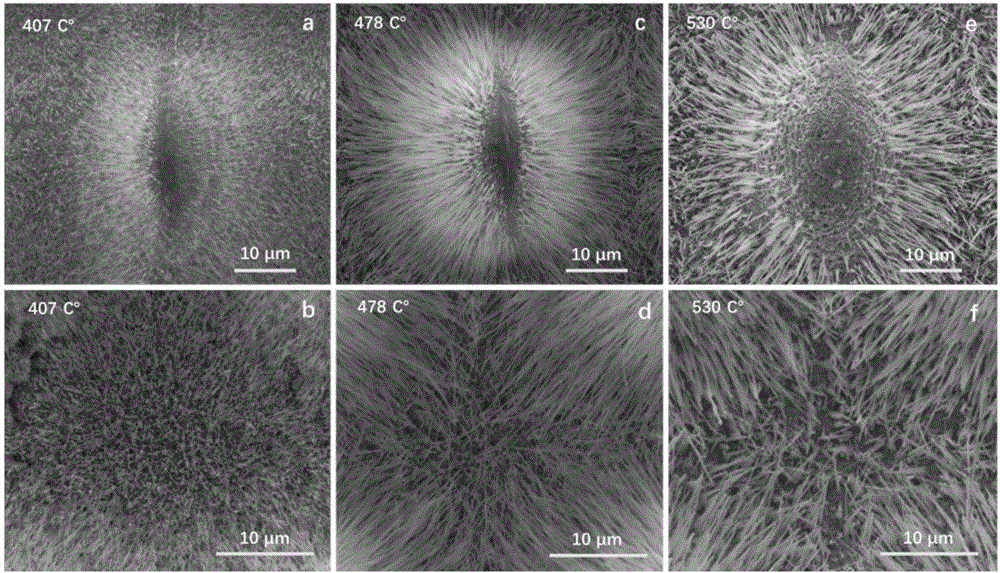

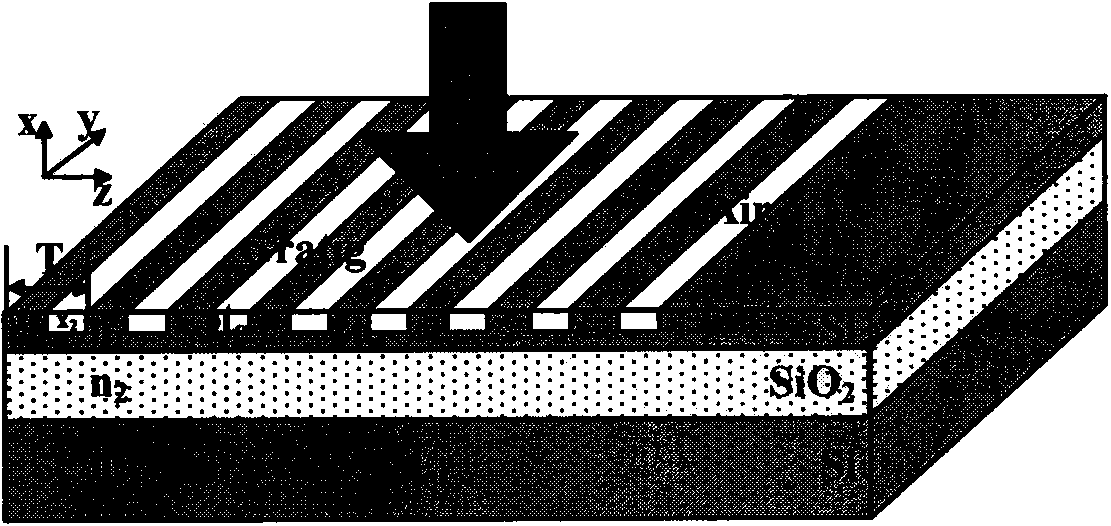

Micro-nanostructure controlled copper-based superhydrophobic surface and preparation method and application thereof

InactiveCN107522161AReduce pollutionEasy to mass manufactureSemi-permeable membranesVolume/mass flow by thermal effectsMicro structureNanowire

The invention discloses a micro-nanostructure controlled copper-based superhydrophobic surface and a preparation method and application thereof. The copper-based superhydrophobic surface comprises micro structure arrays and nanowires, wherein center spacing of the micro structure arrays is 10 to 500[mu]m, the height of each micro structure array is 5 to 500[mu]m; the nanowires have the diameter of 40 to 200nm, the length of 2 to 50[mu]m and average spacing of 0.1 to 3[mu]m; and the nanowires grow in parallel to the direction of a local normal of the copper-based superhydrophobic surface and has the ingredient being copper oxide. The copper-based superhydrophobic surface can implement liquid droplet bouncing heat exchange of water vapor condensation and can also promote classical droplet condensation so as to reinforce heat exchange. Moreover, the micro-nanostructure controlled copper-based superhydrophobic surface can also be used for the fields of self-cleaning, corrosion resistance, ice prevention, frosting resistance and the like.

Owner:TSINGHUA UNIV

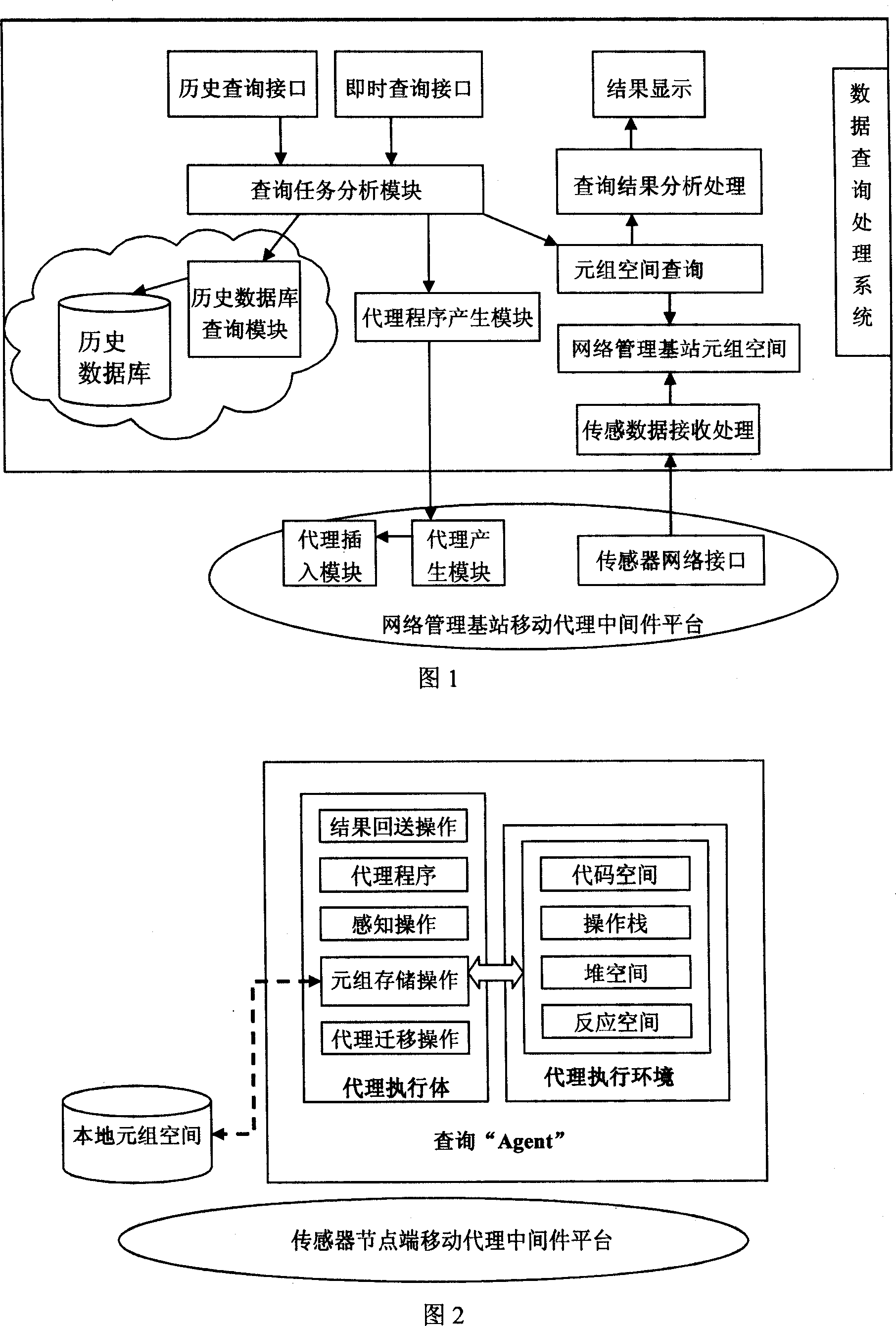

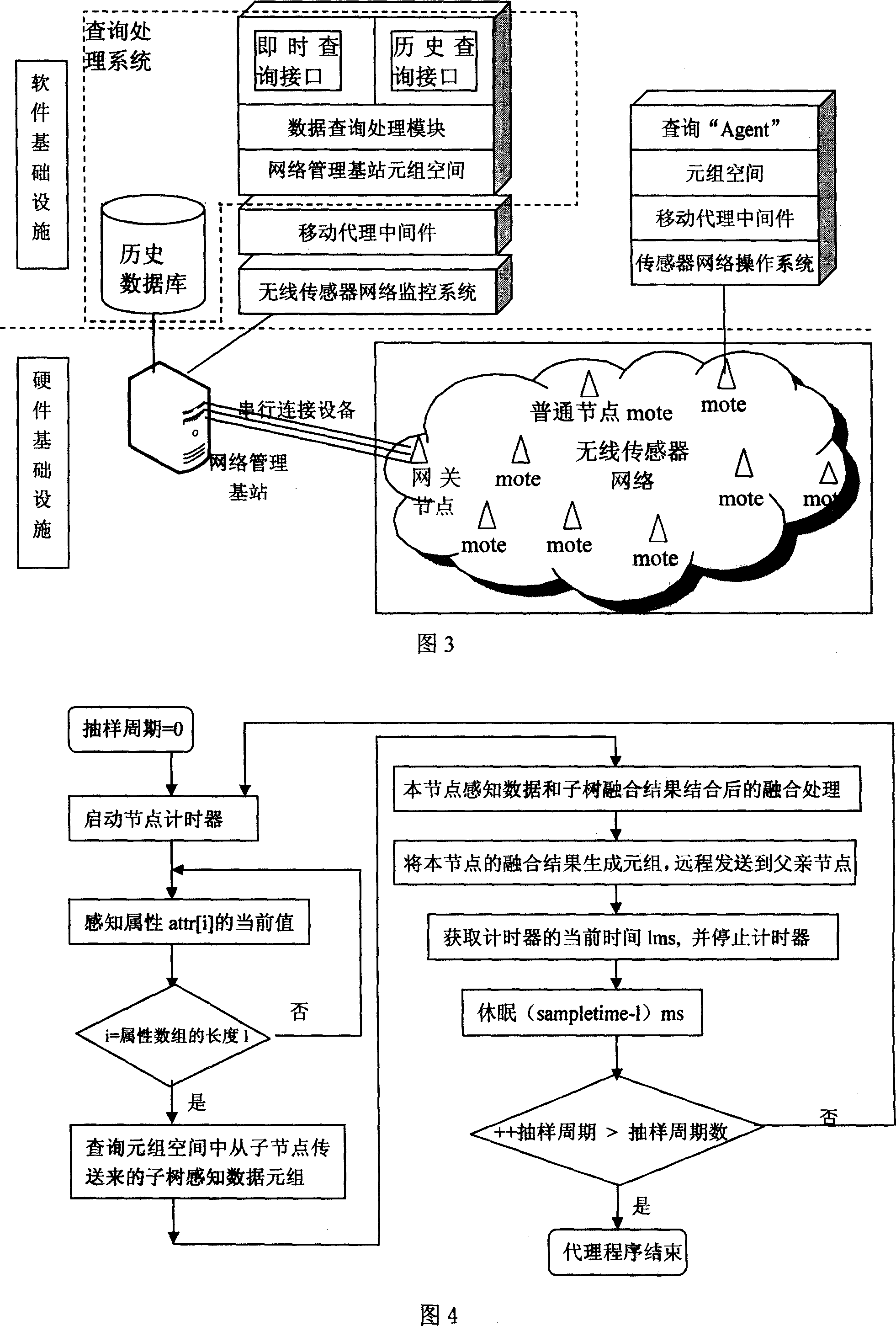

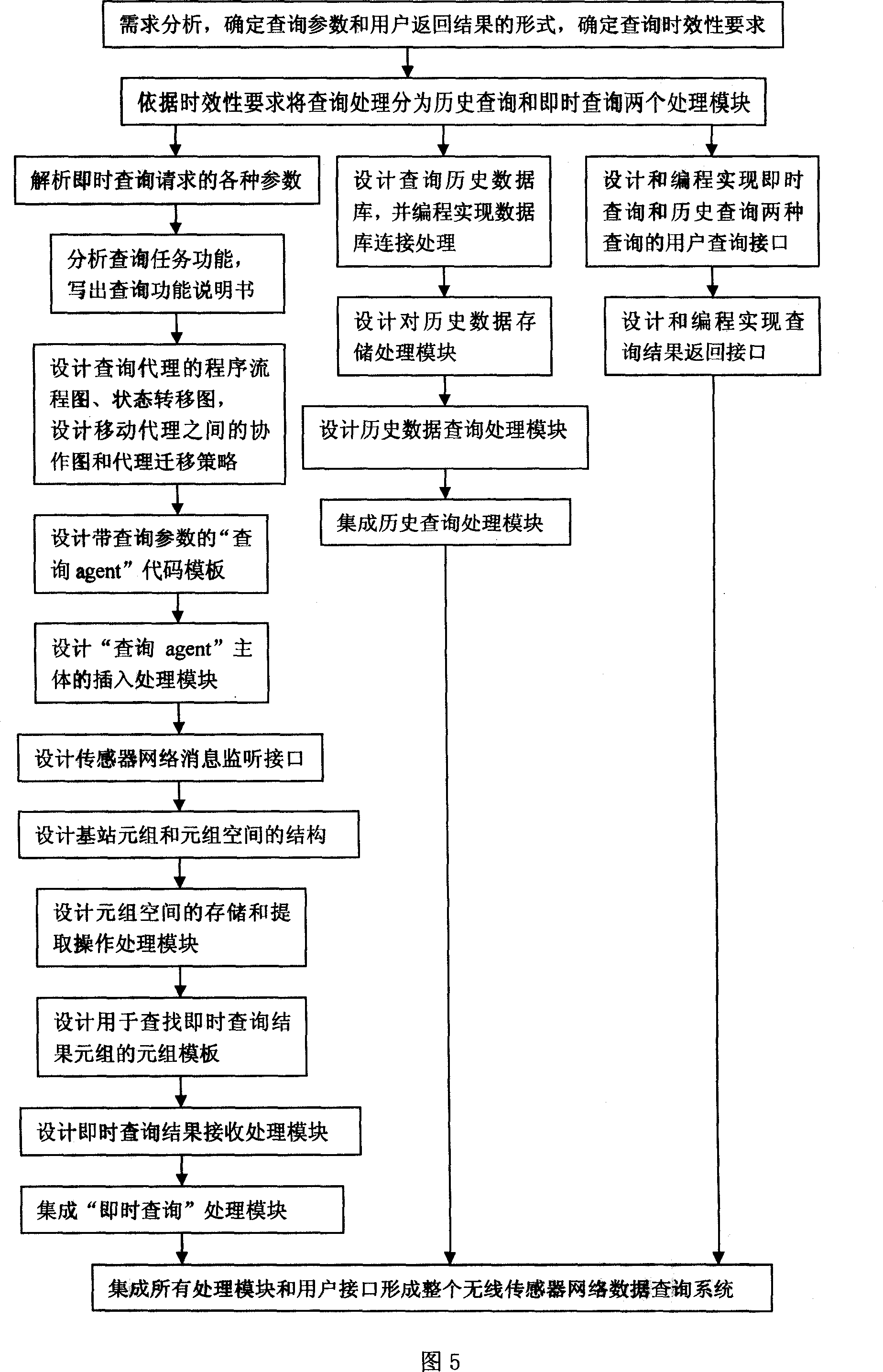

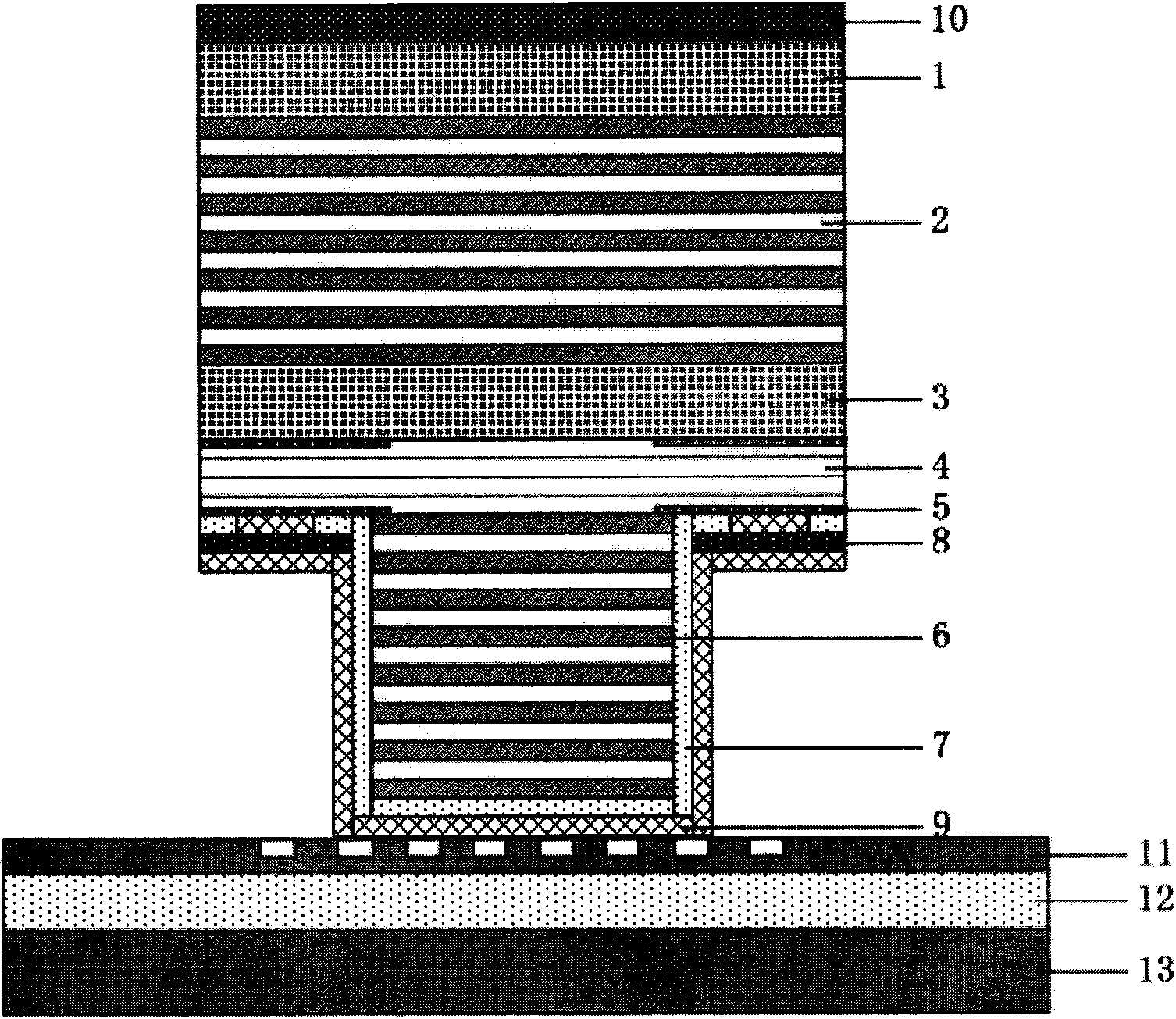

Method for realizing data inquiring system of sensor network based on middleware of mobile agent

InactiveCN101013986AImprove development efficiencyImprove deployment efficiencyData switching by path configurationSpecial data processing applicationsProcess systemsHandling system

The invention relates to one sensor network data inquire process method based on mobile agent middle part, which comprises the following steps: regarding whole wireless sensor as one database; realizing on mobile agent middle part; executing user inquire task by mobile agent onto designed point to start operations till fulfilling inquire task to end its life circle or according to its task need onto other point; inquiring process system design to realize network base station to change inquire agent design.

Owner:NANJING UNIV OF POSTS & TELECOMM

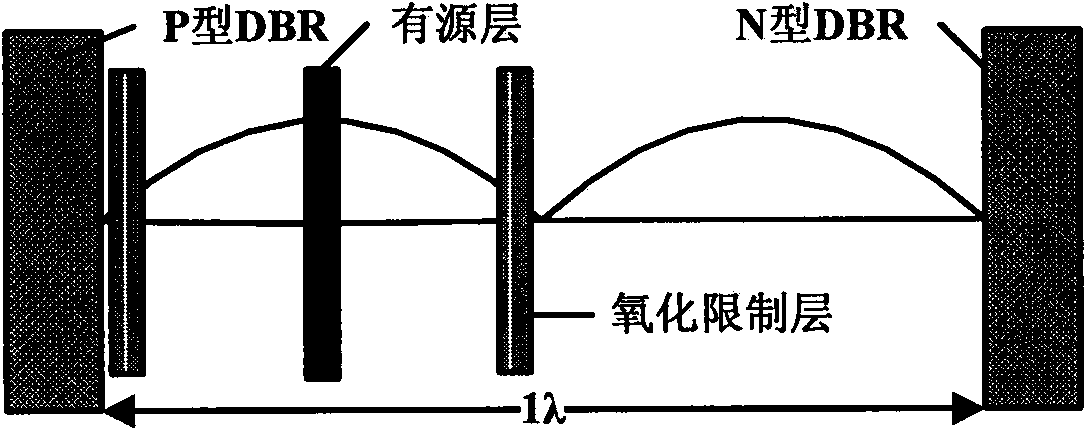

Preparation method and application of 1550 nm long wavelength vertical-cavity surface-emitting laser

InactiveCN104051957AIncrease output powerSimple manufacturing processLaser detailsSemiconductor lasersLong wavelengthVertical-cavity surface-emitting laser

The invention discloses a 1550 nm long wavelength vertical-cavity surface-emitting laser with an InGaAsN / AlGaInAs QWs as an active layer. The laser is characterized in that the InP-based InGaAsN / AlGaInAs QWs and AlGaAsSb / AlAsSb are used as DBR materials of the active layer. The length of a resonant cavity of the laser is 1 lambda so that the better light emitting effect can be achieved. In addition, the performance of the surface-emitting laser is further improved by the adoption of a double-layer oxidation limiting layer structure, single-mode output power is improved, and 1550 nm long wavelength transmission is achieved. The laser comprises a P-type DBR layer, the active layer, an N-type DBR layer, a substrate, a SiO2 insulating layer, a transparent conducting medium ZnO, a P-type electrode and an N-type back electrode. The whole structure achieves lattice matching in material, so that the epitaxy technology can be widely applied. The vertical-cavity surface-emitting laser is simple in manufacturing technology, good in repeatability and easy to popularize.

Owner:TIANJIN POLYTECHNIC UNIV

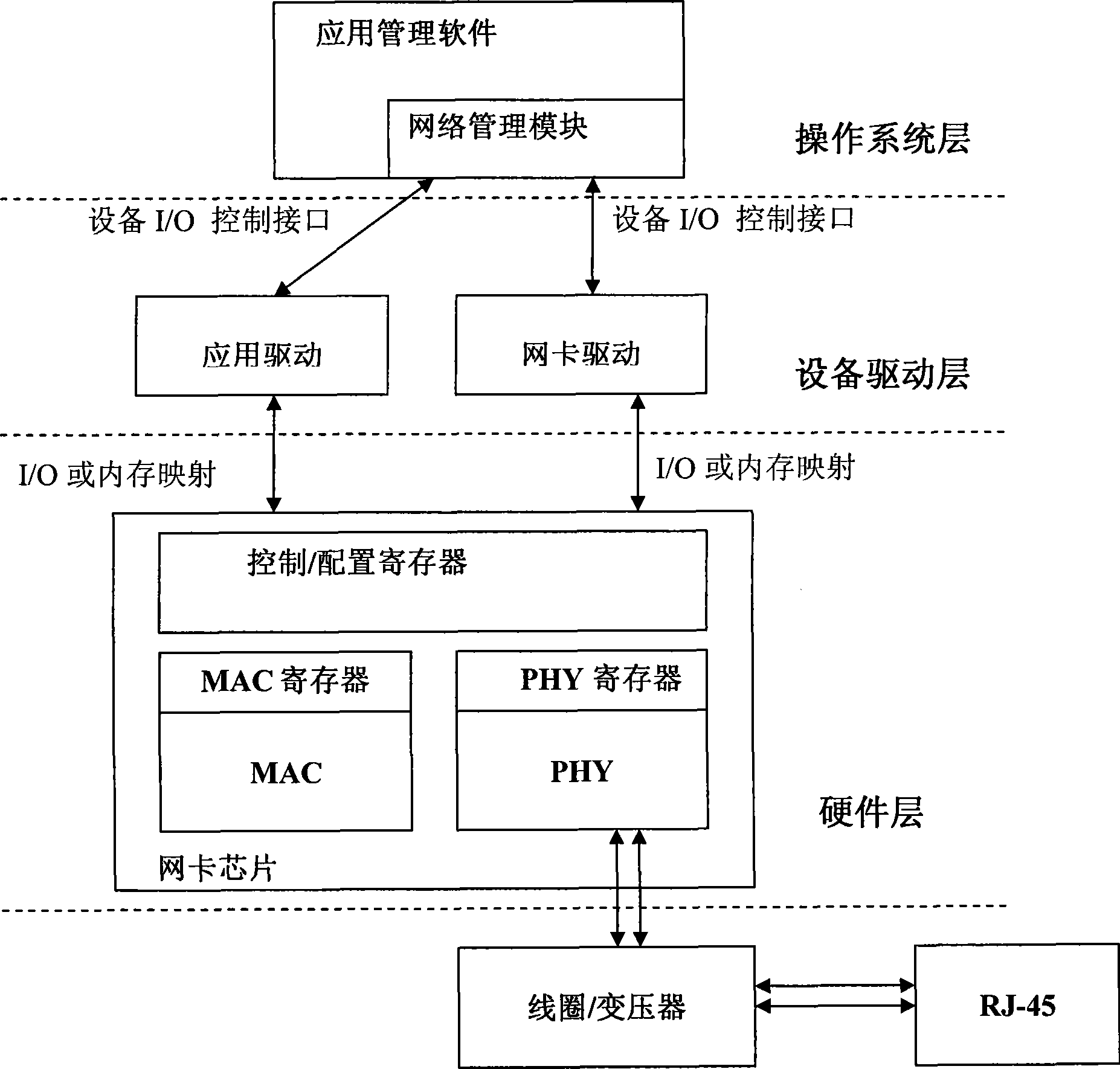

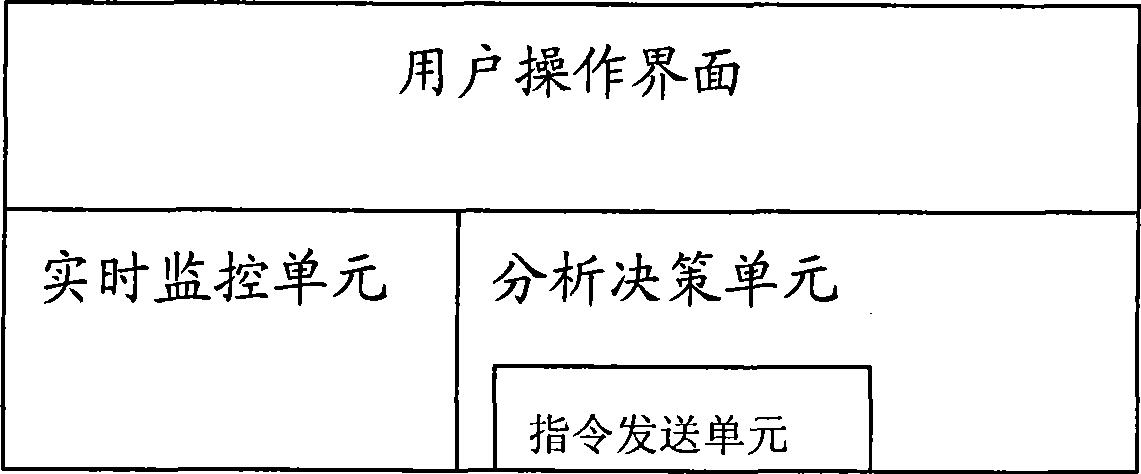

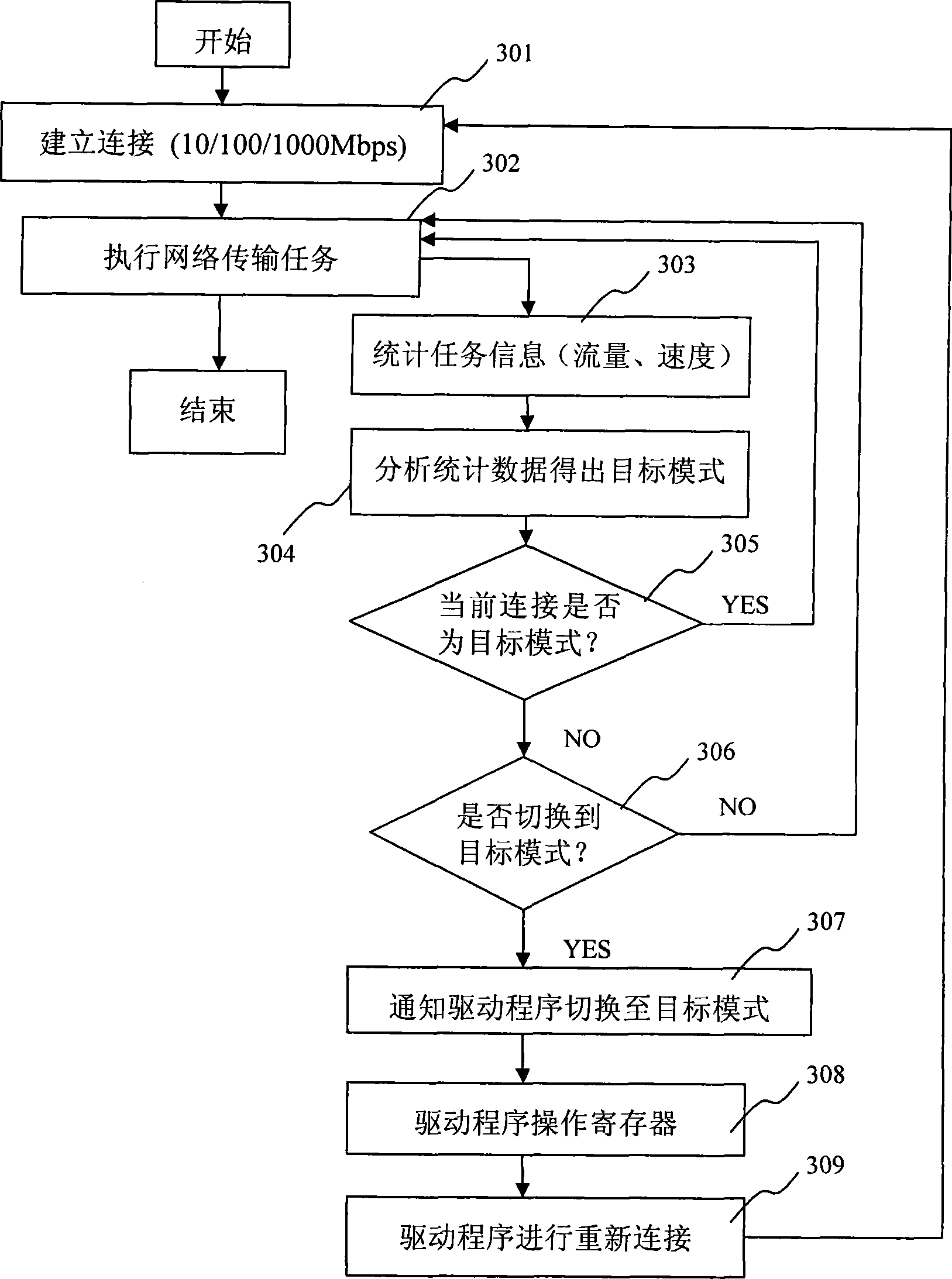

Dynamic control method and device for network card power consumption and connection mode

InactiveCN101458556AIncrease profitExcellent dynamic matchingError preventionPower supply for data processingProcess dynamicsNetwork connection

The invention provides a dynamic control method of a network card consumption and connection mode which belongs to the power saving technique, and a device thereof. The method includes: monitoring data transmitting state of network in real-time, obtaining statistic value of data transmitting state in existing or scheduled time period; obtaining an object connecting mode matched with existing data transmitting, switching the network connecting mode into the object connecting mode. In an embodiment, network connection is not forced in certain connection mode, realizes dynamic changing connecting mode according with load assignment by monitoring data transmitting state of network and comparing with switch condition, can process dynamic switch among various mode, increases utilization rate of transmitting band width and realizes optimizing dynamic match of band width / energy consumption.

Owner:LENOVO (BEIJING) LTD

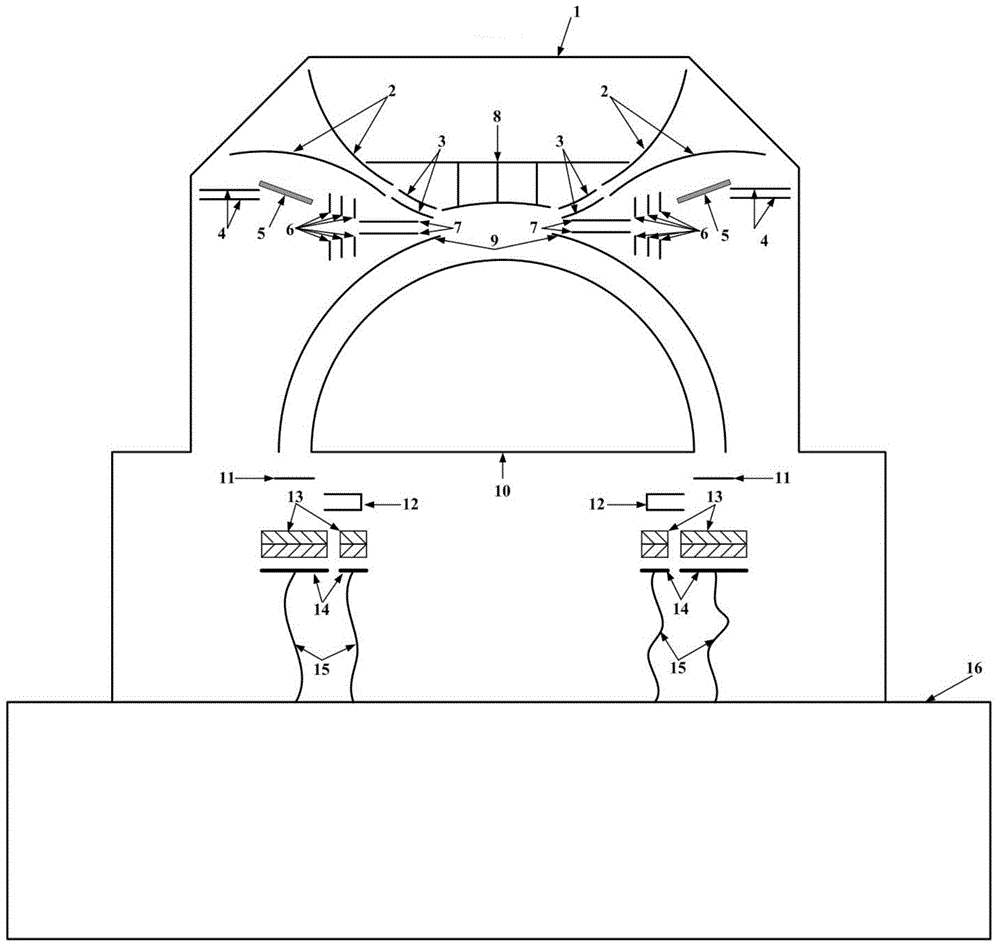

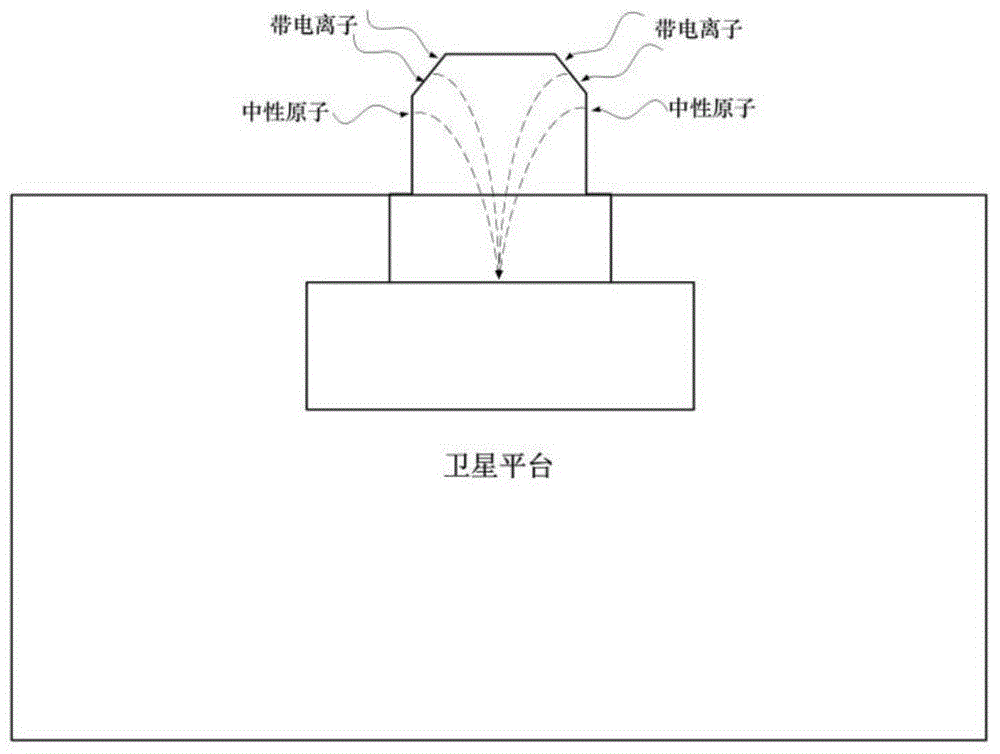

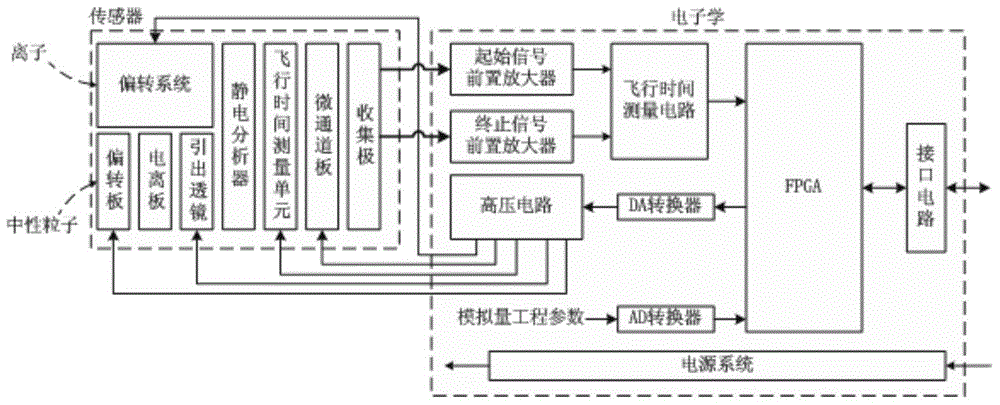

Measurement device used for space ions and neutral atoms

InactiveCN105990089AReduce resource requirementsReduce weightTube electrostatic deflectionMass spectrometersMeasurement deviceParticle physics

The present invention provides a measurement device used for space ions and neutral atoms. The measurement system comprises an ion deflection system, a neutral atom ionization deflection system, an electrostatic analyzer, a flight time system, an electronics processing unit and a device shell. The back-end electrostatic analyzer, the flight time system and the electronics processing unit are shared to measure the ions generated by ionizing the neutral atoms and the ions radiated from the space directly, the measurement of the space ions and the neutral atoms is integrated in a probe, and the as much as possible measurement parts are shared, so that the weight and the power consumption of the device are reduced furthest, the requirements for the satellite platform resources are also reduced, and the fields to which the device is applied are expanded. The measurement device of the present invention has the wide application demands both in the terrestrial space field and the deep space exploration field.

Owner:NAT SPACE SCI CENT CAS

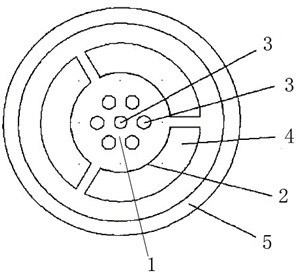

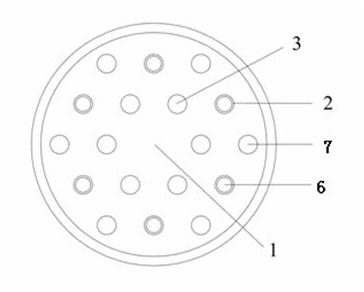

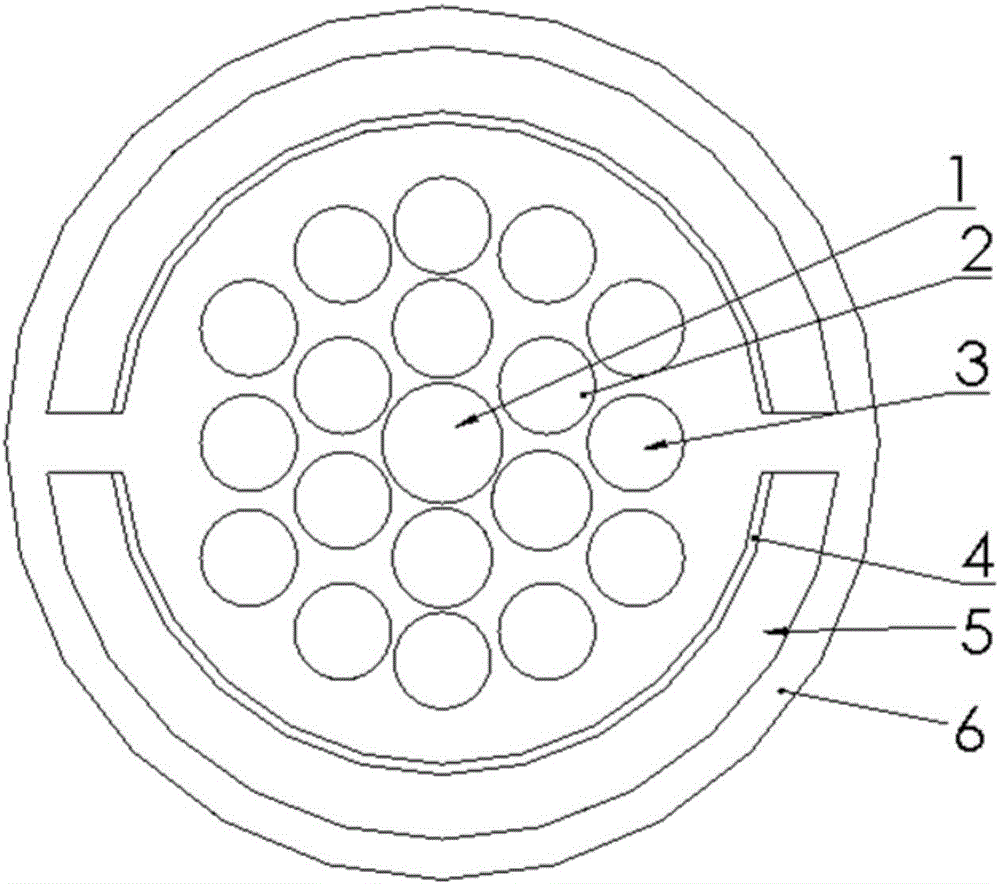

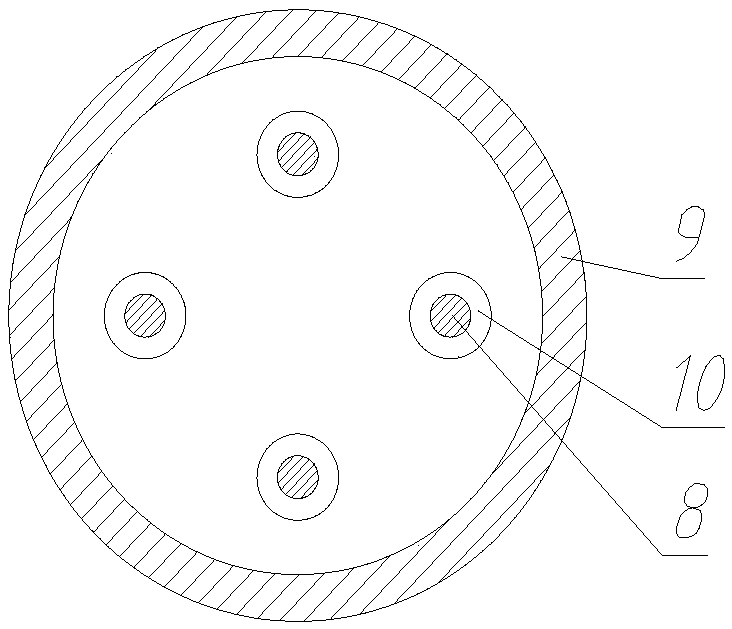

Microstructure fiber sensor

ActiveCN102445436AReduce volumeStable structurePhase-affecting property measurementsAperture arrayRefractive index

The invention relates to a microstructure fiber sensor in the field of biochemistry sensing. The microstructure fiber includes an inner ring of air apertures and an outer ring of air apertures; the outer ring air apertures comprise two varieties of apertures of inner film plated apertures and non-inner film plated apertures, which are respectively used as sample channels. The outer ring film plated apertures are used as SPR detection channels for measuring a sample with a refractive index lower than that of a background fiber material. The outer ring non-film plated apertures are used for detecting a sample with a refractive index higher than that of the background fiber material. The inner ring air apertures and the outer ring air apertures, and the outer ring film plated apertures and non-film plated apertures are in a periodically arranged aperture array structure, so as to realize two detection mechanisms of surface plasmon resonance and coupling resonance in one structure; therefore, detection scope of a sensor is effectively expanded and not restrained by the sensor background material any more, thereby satisfying wider application demand. The invention also has advantages of small volume, simple structure and easiness for packaging.

Owner:HUAZHONG UNIV OF SCI & TECH

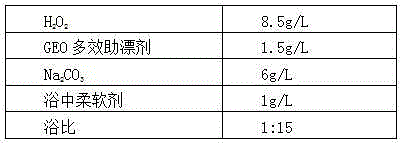

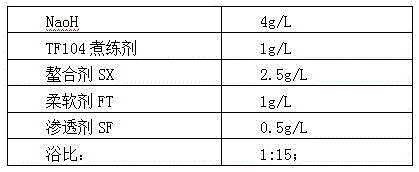

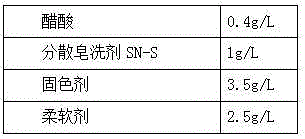

Preparation method of knitted wool-like warm fabric

InactiveCN105332155AGood dissipationHigh pectinWeft knittingBiochemical fibre treatmentYarnPolymer science

The invention relates to a preparation method of a knitted wool-like warm fabric. The preparation method comprises the following steps: (1) raw material selection; (2) spinning technology implementation; (3) weaving technology implementation; (4) printing, dyeing and after-finishing. The knitted wool-like warm fabric is formed by performing the after-finishing, such as knitting, dyeing, carbon grinding and softening, on hemp / cotton / polypropylene fiber blended yarns and polyolefin elastic fibers, namely confirmable elastic fibers, which serve as raw materials. By the adoption of hemp, a product can realize antibacterial, health care and anti-ultraviolet functions; cotton fibers are high in hygroscopicity and spinnability; the polypropylene fibers are poor in heat conductance and high in heat insulation property; by the blending of the three types of fibers, a product has the functions of heat insulation, moisture absorption, breathing, bacteria prevention and ultraviolet resistance; by the weaving of the polyolefin elastic fibers, the product is extremely high in elasticity and conformality. The product is soft, fine, breathable, relaxing, high in heat retention property and suitable for making high-end warm coats or skirts, is a high-quality antibacterial, health care and warm fabric which has a wide market development prospect.

Owner:JIANGSU YDTEX GRP LTD

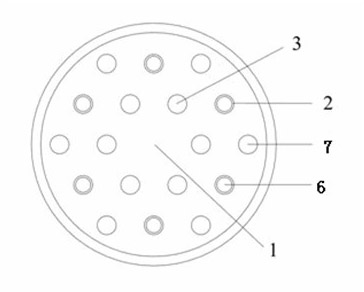

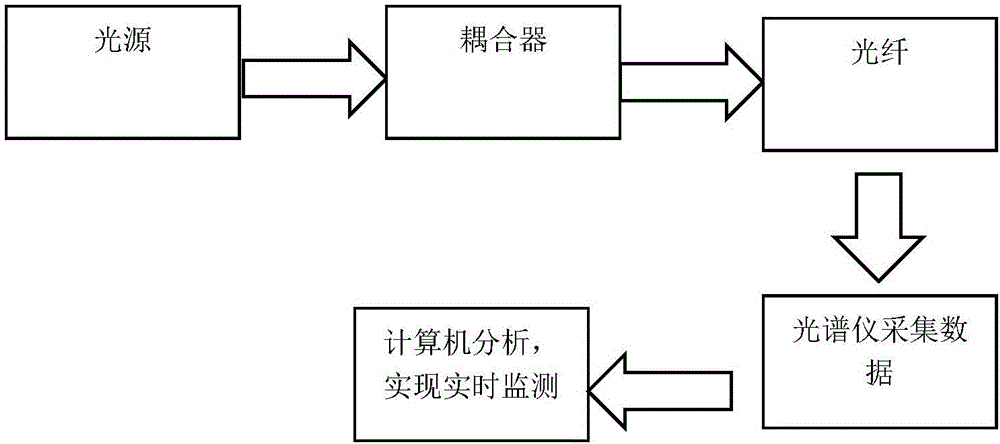

Optical fiber sensor and device based on plasma resonance

InactiveCN106770057AStable structureEasy to manufactureMaterial analysis by optical meansLiquid mediumPlasma resonance

The invention discloses an optical fiber sensor and device based on plasma resonance. The optical fiber of the sensor is internally provided with a plurality of layers of air holes, and the air holes include a central air hole, a first air hole layer, a second air hole layer and a fan annular air hole which are formed from inside to outside, wherein each of the first air hole layer and the second air hole layer contains a plurality of independent air holes; the central air hole is formed in the center of the optical fiber, the first air hole layer, the second air hole layer and the fan annular air hole are arranged symmetrically with the central air hole as a symmetrical center, each of the first air hole layer and the second air hole layer has a hexagonal shape, and the side of the fan annular air hole, adjacent to the center, is coated with a film; and the central air hole and the second air hole layer are filled with air mediums, the first air hole layer is filled with a metal medium, and the fan annular air hole is filled with a liquid medium to be detected. The optical fiber sensor has the advantages of simple manufacture, high sensitivity and better comprehensive performance, the detection range of the sensor can be effectively enlarged, and wider application demands can be met.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

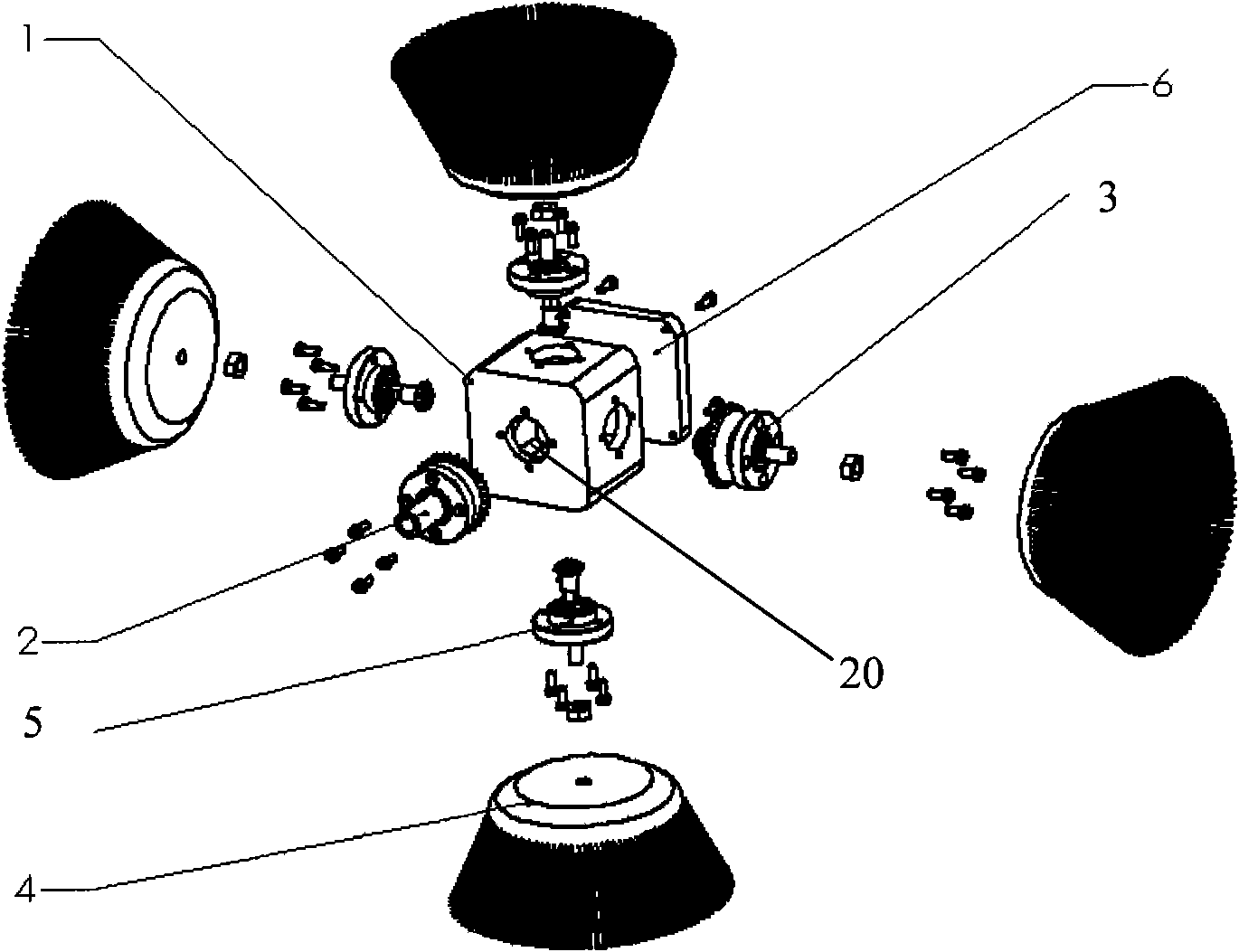

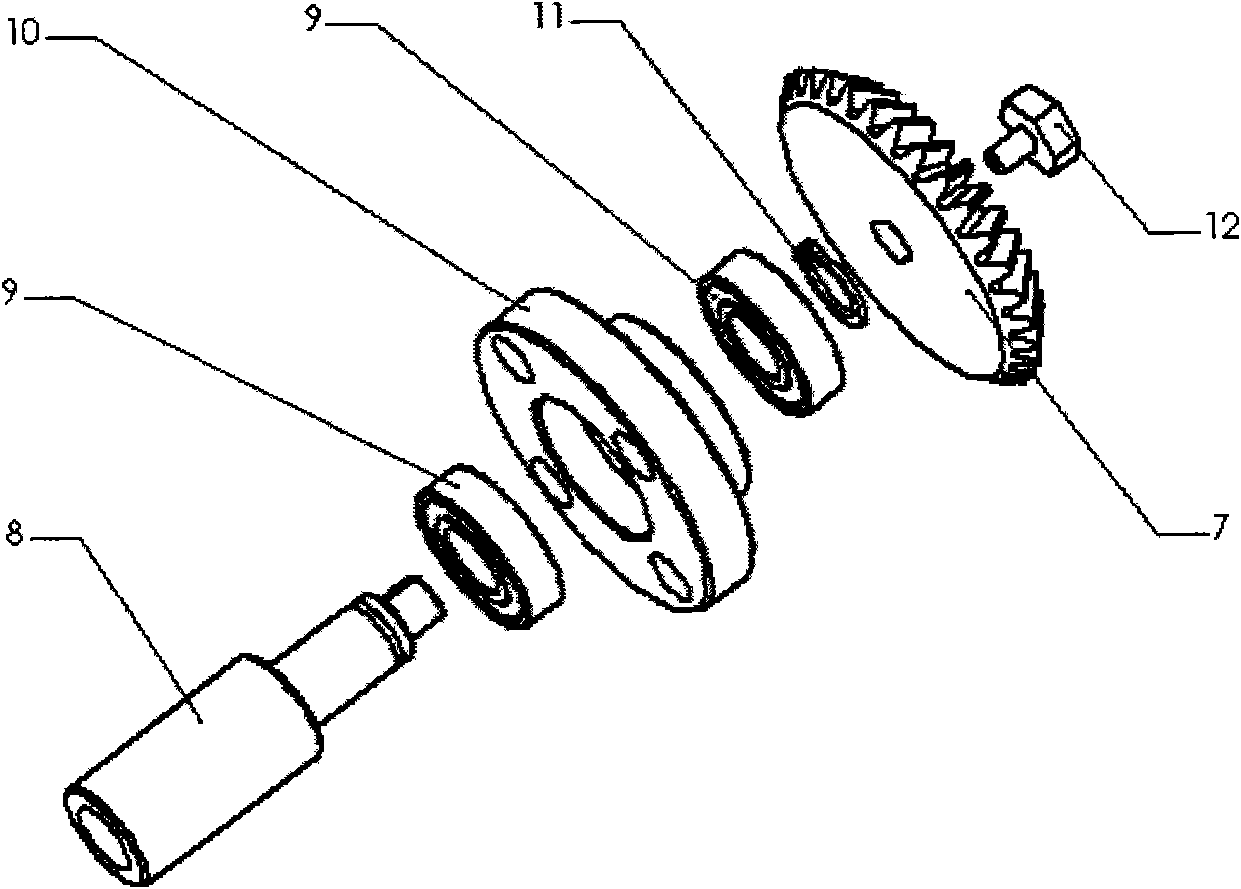

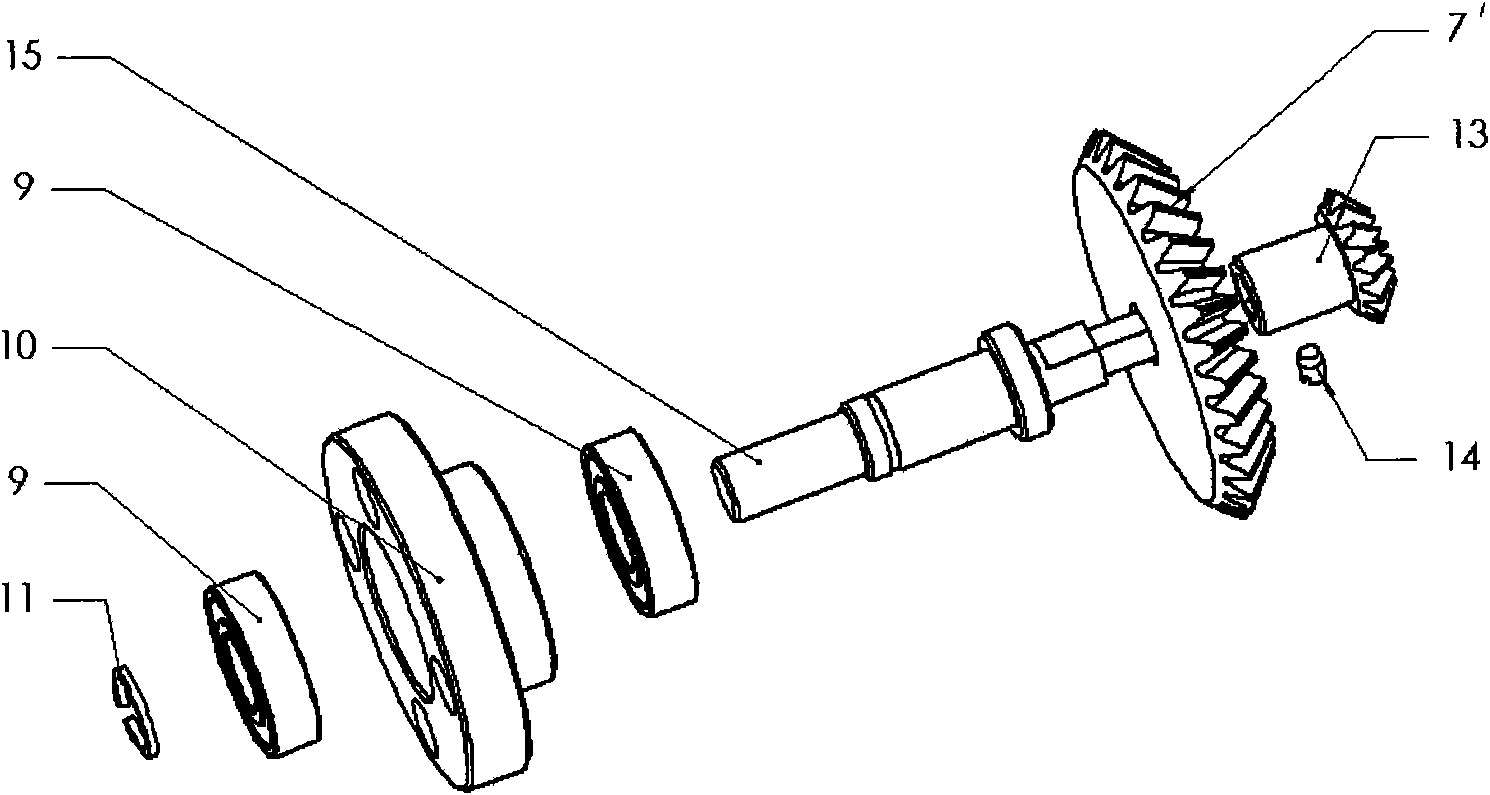

Scavenging machine for air-condition pipeline

The invention relates to a scavenging machine for an air-condition pipeline, which comprises a shell, a power input mechanism arranged in the shell, a first turning mechanism, at least one second turning mechanism and bushes arranged on the first turning mechanism and the second turning mechanism, wherein an input shaft for connecting a power source is arranged on the power input mechanism; output shafts for installing the brushes are arranged on the first turning mechanism and the second turning mechanism; the input shaft exposes out of one end of the shell; a plurality of output shafts expose out of different lateral surfaces of the shell respectively; the power input mechanism, the first turning mechanism and the second turning mechanism are correspondingly provided with transmission mechanisms; and the power source provides power to the input shaft and realizes the turning and the rotation of the first turning mechanism and the second turning mechanism through the transmission of the transmission mechanism and drives the brushes to rotate through the output shafts. The scavenging machine for the air-condition pipeline integrates a multi-turning function into a whole body; the turning mechanisms can realize turning running so that the scavenging machine can sweep simultaneously in multiple directions; and the scavenging machine for the air-condition pipeline has the advantages of simple structure, reliable operation and wide range of application requirement, and has huge market development potential.

Owner:JOHNSON ELECTRIC SHENZHEN

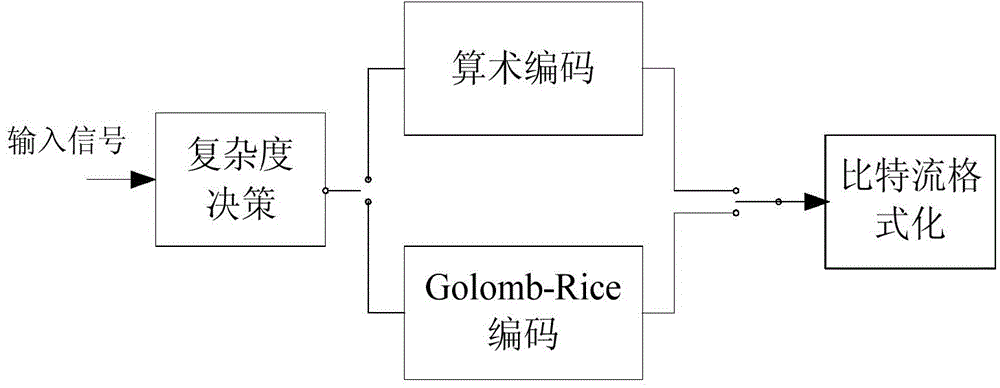

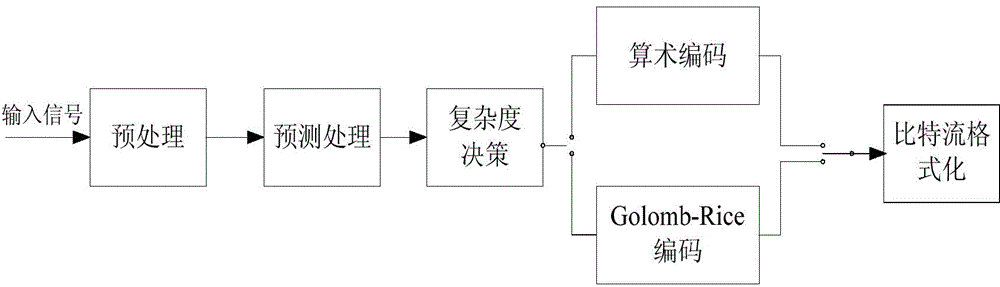

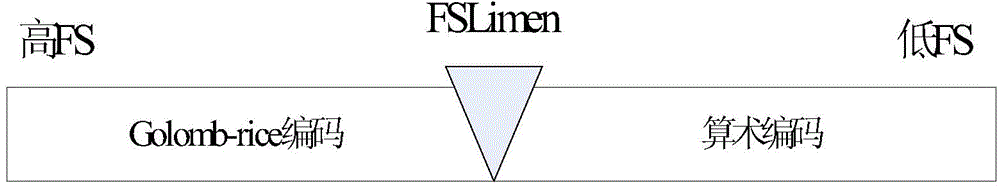

Method and device for hybrid coding/decoding of multi-channel lossless audios

InactiveCN104392725AWide range of application requirementsLow costSpeech analysisVocal tractPre treatment

The invention discloses a method and a device for hybrid coding / decoding of multi-channel lossless audios. In the method and the device, the coding / encoding of an algorithm and a Golomb-rice entropy is chosen according to sampling frequency, quantity of the channels, digitalization bits and computing complexity of a pre-treatment module and a predication module; and the hybrid coding / decoding of the algorithm and the Golomb-rice for multi-channel lossless audio signals is realized by the respective coding / decoding advantages of the algorithm and the Golomb-rice entropy. For the consideration of the balance between the entropy coding complexity and the coding / decoding efficiency, a hybrid entropy coding method applicable to the multi-channel lossless audio data is provided; the switching between the coding / decoding complexity and the coding / decoding speed can be realized by using the method; and wider application requirements can be satisfied according to the difference of the operational capabilities of processors of a coders and an encoder. The high-quality coding for the multi-channel lossless audios can be realized and the hardware cost is reduced effectively.

Owner:中科开元信息技术(北京)有限公司

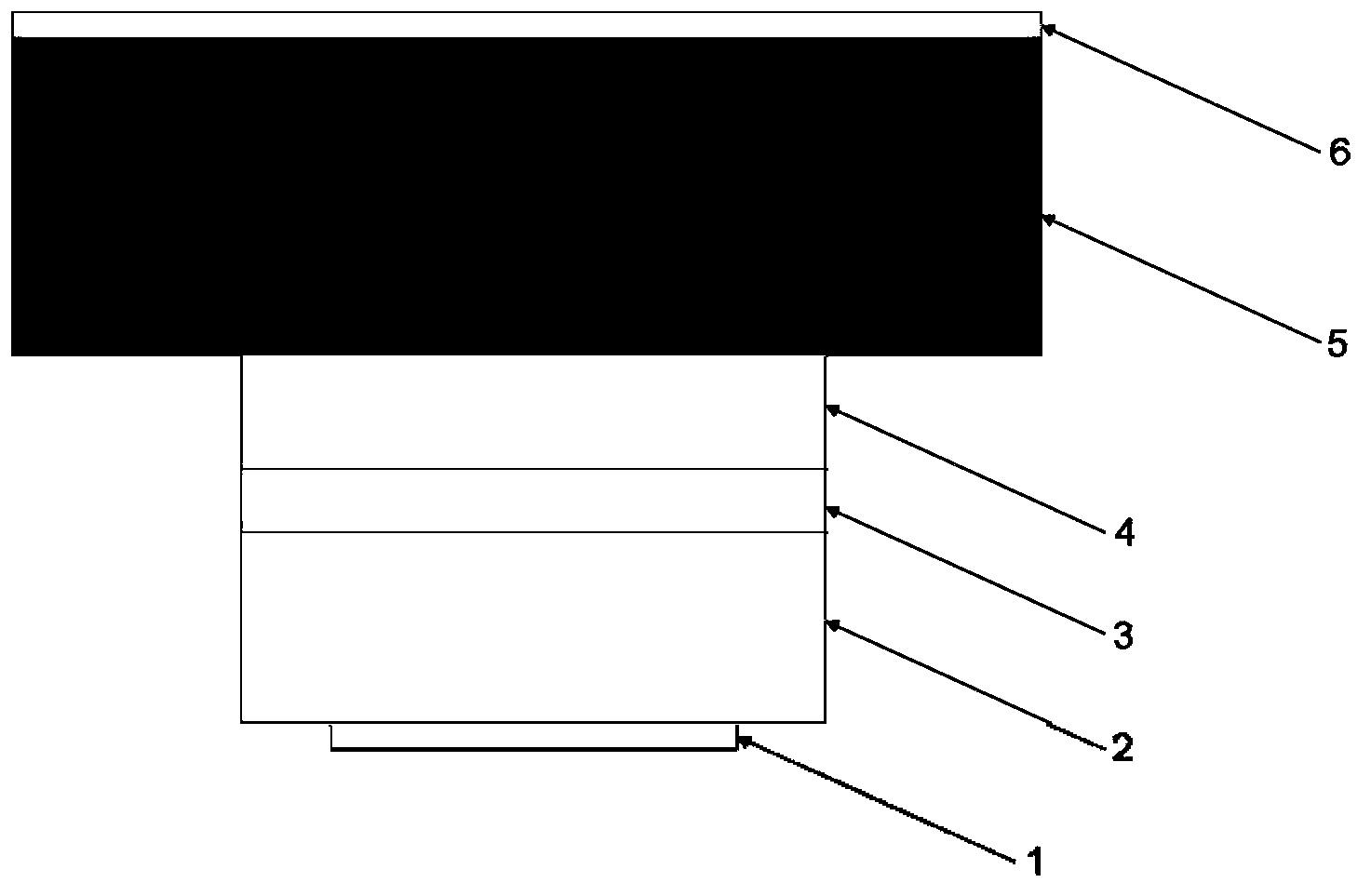

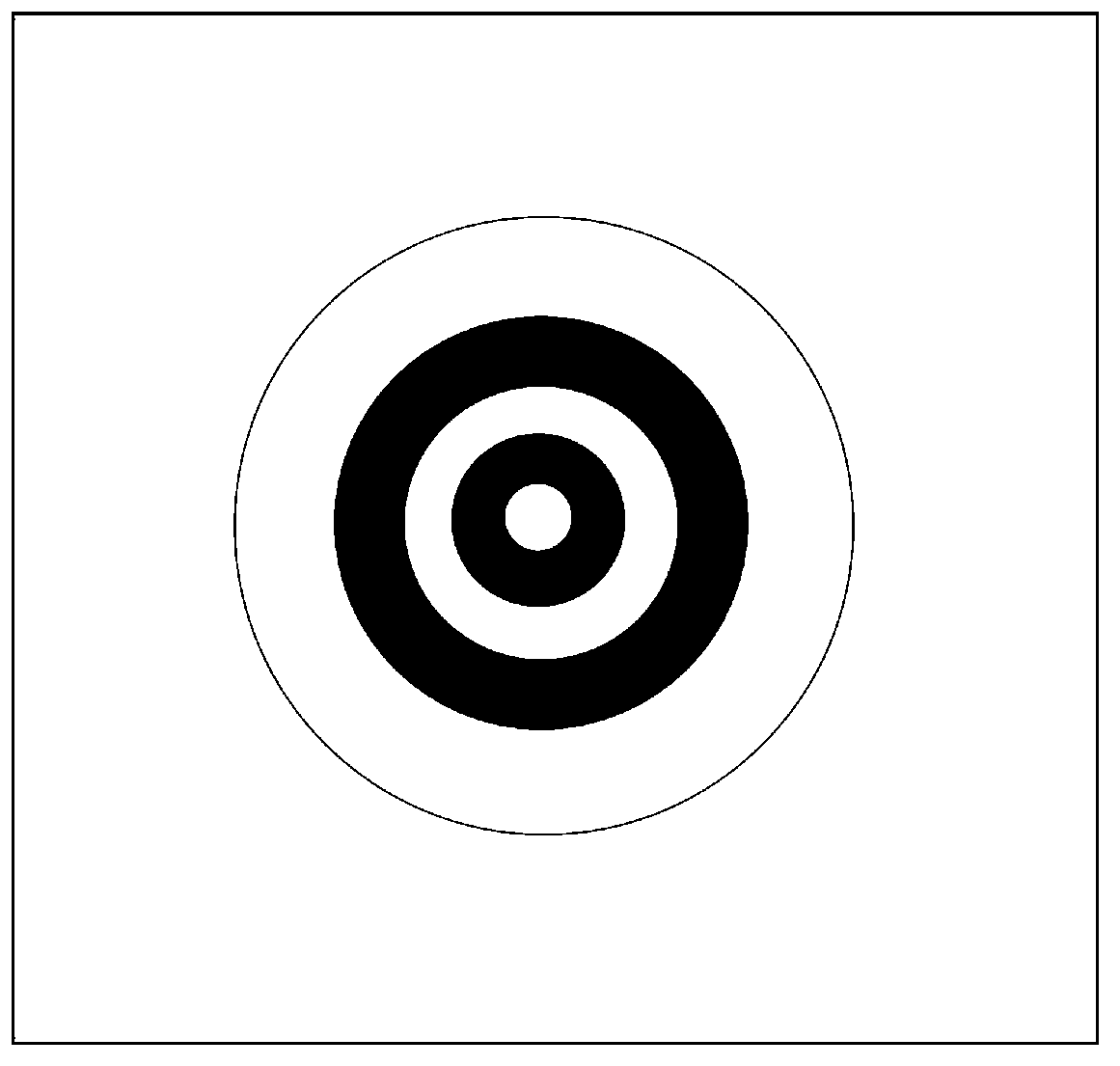

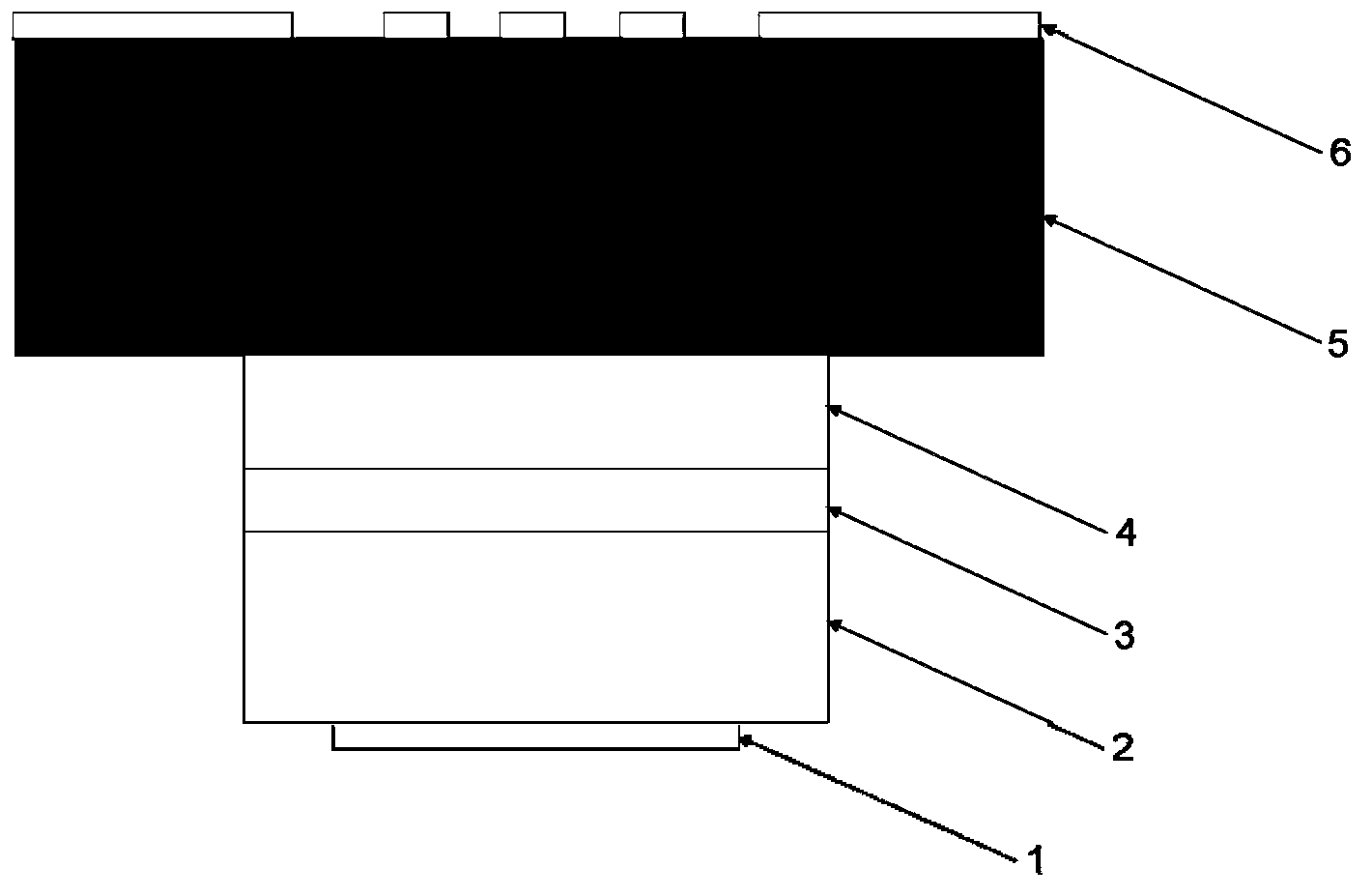

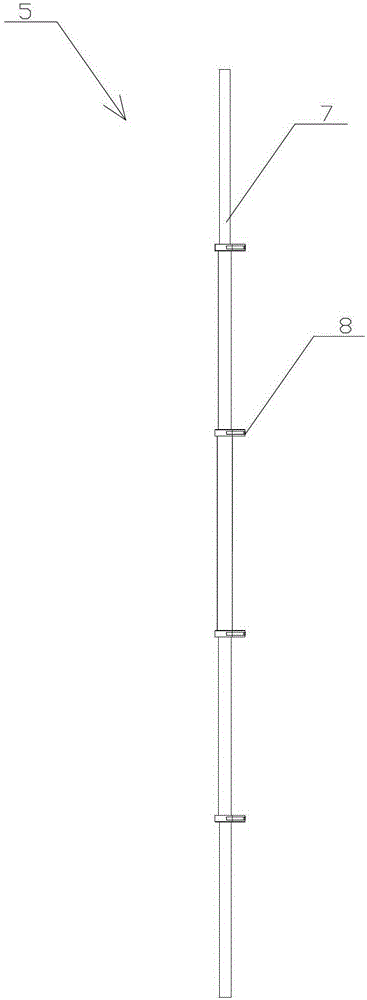

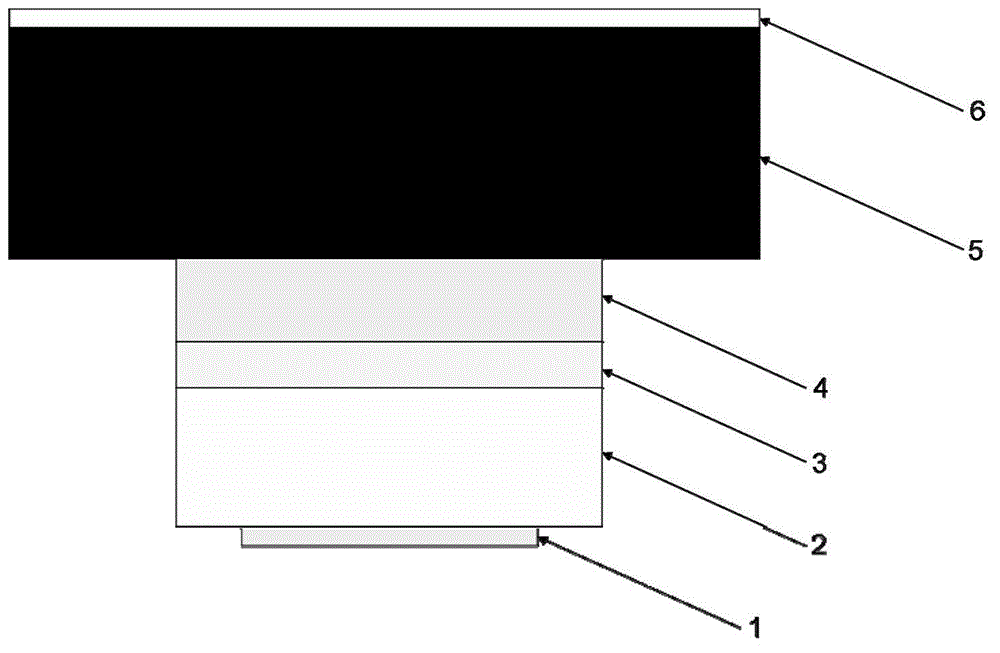

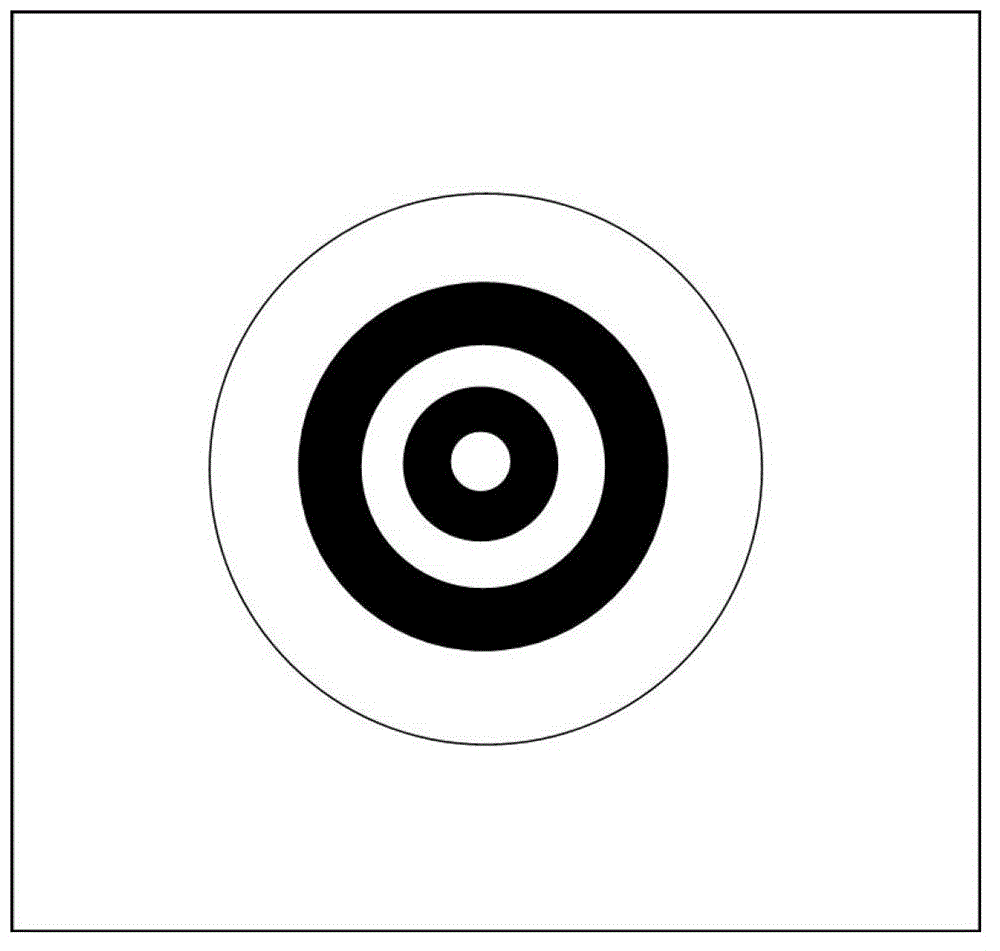

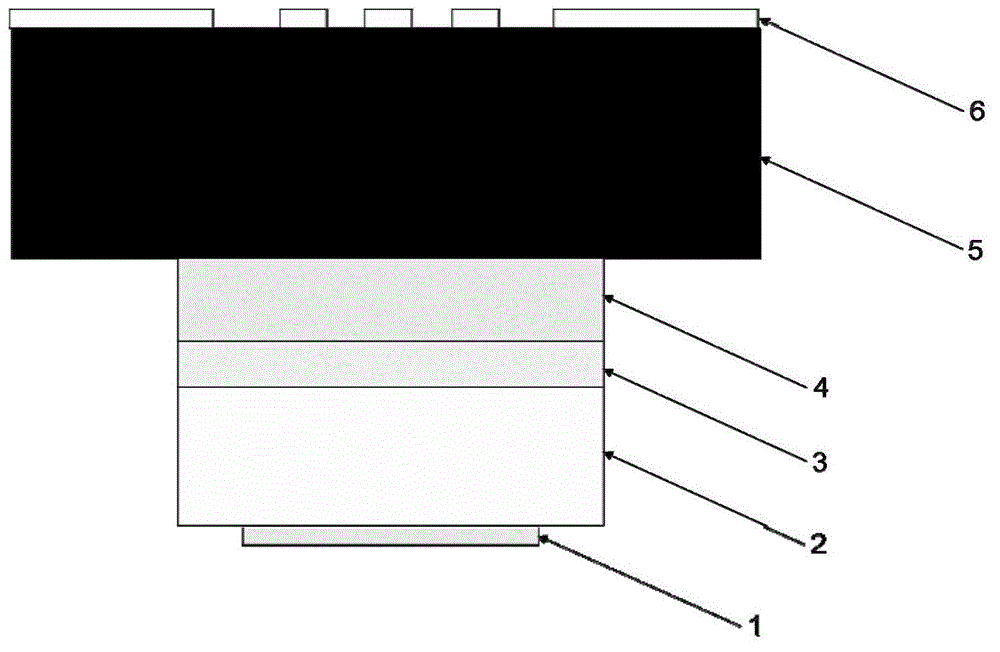

Vertical-cavity surface-emitting laser capable of automatically focusing

ActiveCN103178443ASimple manufacturing processGood repeatabilityLaser detailsSemiconductor lasersLaser power densityLaser light

The invention discloses a vertical-cavity surface-emitting laser capable of automatically focusing, and belongs to the field of semiconductor lasers. The vertical-cavity surface-emitting laser capable of automatically focusing comprises a P-type DBR (distributed Bragg reflective) layer, an active layer, an N-type DBR layer, a lining layer, a lower electrode wrapped on the P-type DBR layer, and an upper electrode laid on the lining layer. A part, covered on a light emitting window, of the upper electrode is shaped in a concentric ring or a structure with unequally spaced grid bars or crossed grid bars, the upper electrode with the above structure can be formed via the lift-off technology by one step, with the upper electrode, output laser light beams can be focused into a point light spot, or a linear light spot or a cross light spot without additionally adding a light beam shaping device, laser power intensity is greatly enhanced partly, and wide application requirements are met. The vertical-cavity surface-emitting laser capable of automatically focusing is simple in manufacturing technology, good in repeatability and easy to popularize.

Owner:长春中科长光时空光电技术有限公司

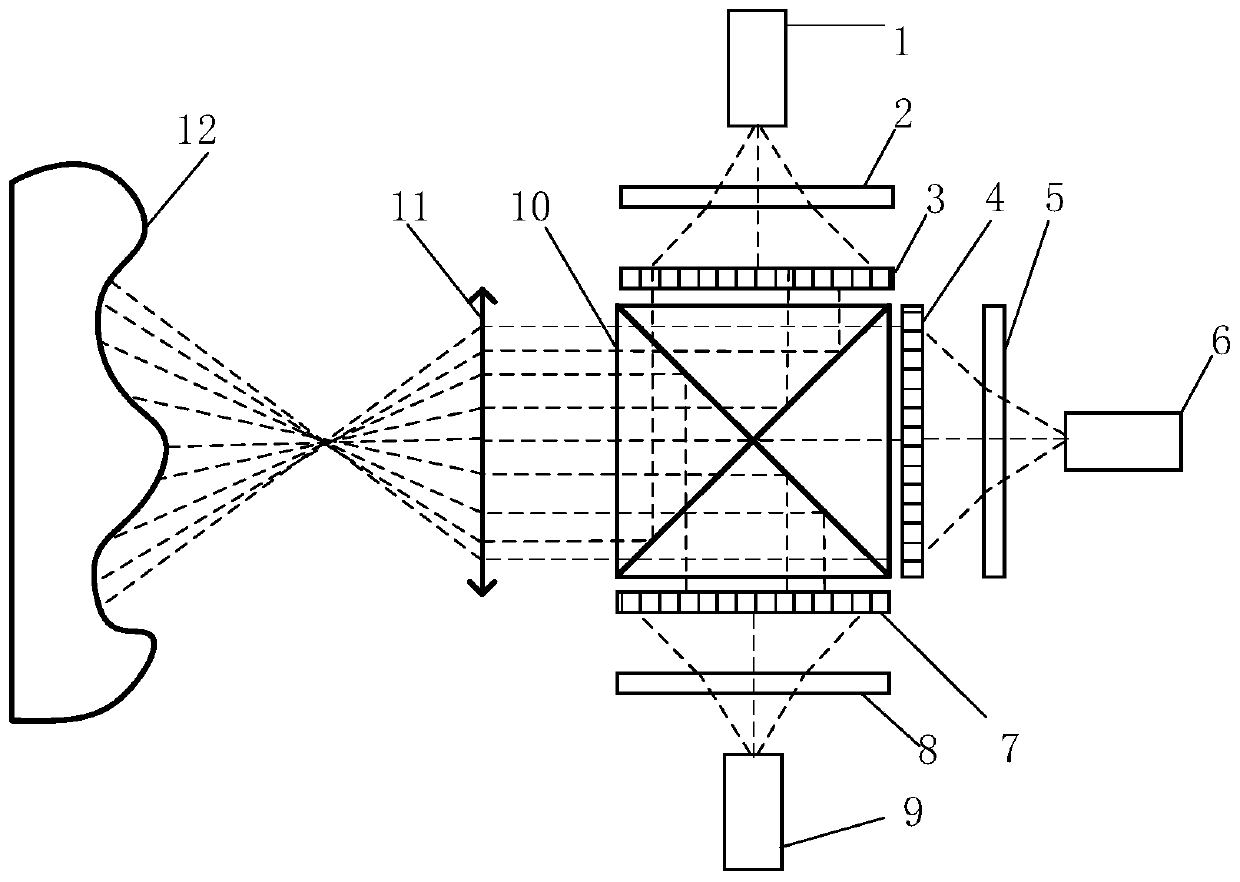

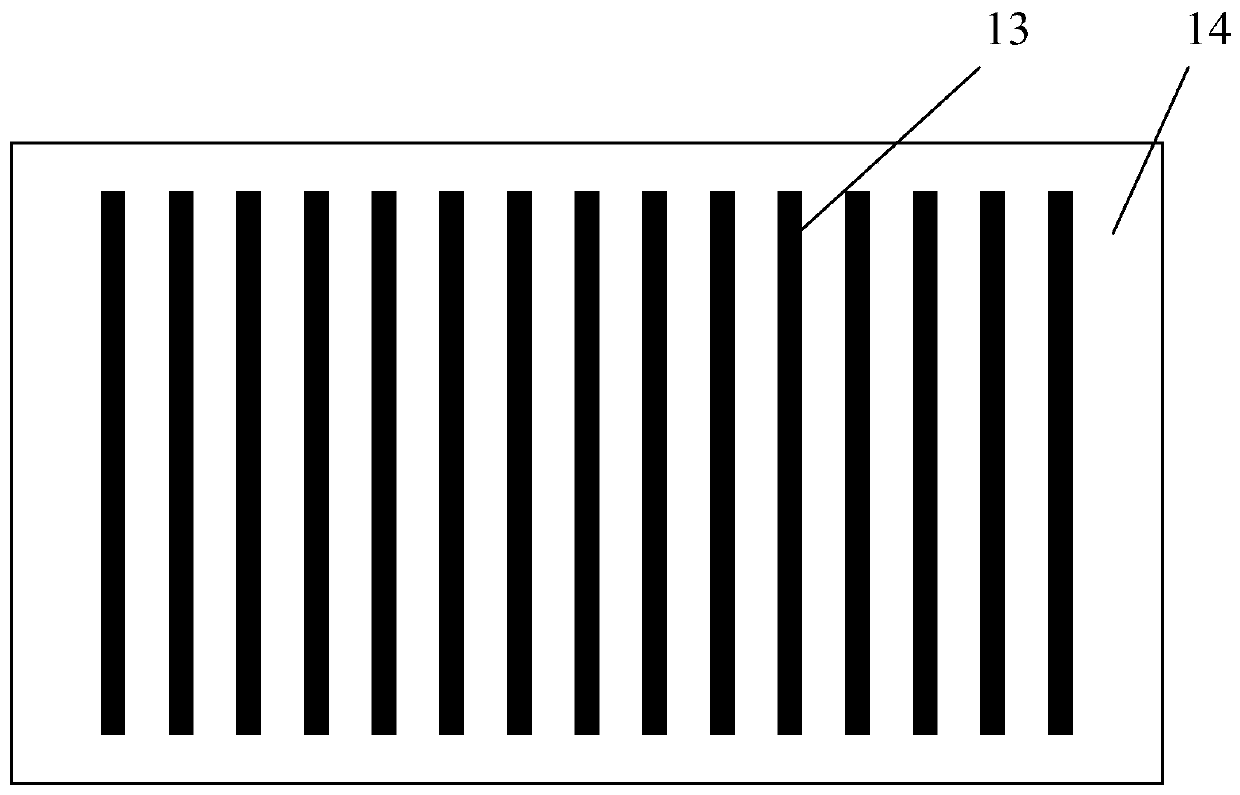

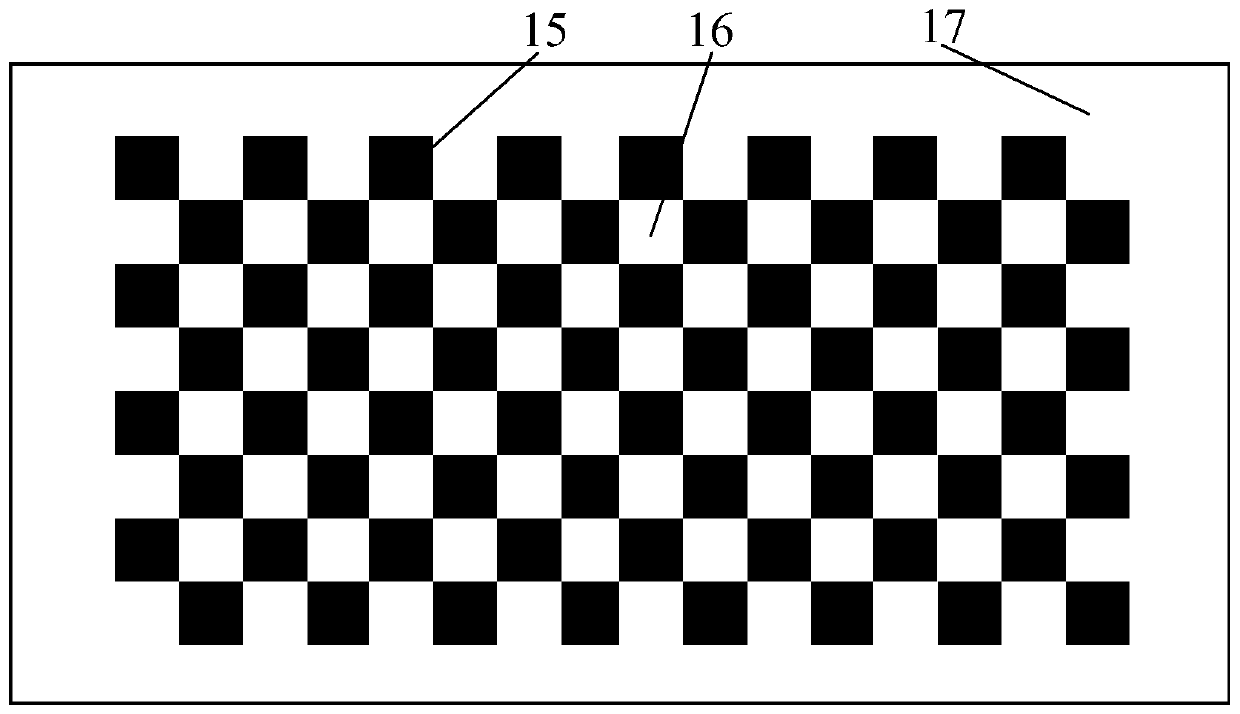

Color structure light projection device

InactiveCN110441981AEliminate stroboscopic effectWide range of application requirementsProjectorsPicture reproducers using projection devicesCamera lensGrating

The invention discloses a color structure light projection device, and belongs to the field of projection display. The projection device comprises a first single-color light source, a second single-color light source and a third single-color light source, wherein the first single-color light source is subjected to light homogenization by a first light homogenization sheet and forms uniform illumination distribution on a first grating; the second single-color light source is subjected to light homogenization by a second light homogenization sheet and forms uniform illumination distribution on asecond grating; the third single-color light source is subjected to light homogenization by a third light homogenization sheet and forms uniform illumination distribution on a third grating; the first grating, the second grating and the third grating are located on three side surfaces of a light combination prism, and are mechanical transmission gratings; distances of the gratings and the corresponding side surfaces of the light combination prism are equal; and a projection lens simultaneously projects images of the first grating, the second grating and the third grating to a to-be-measured three-dimensional object. Relative positions of the mechanical transmission gratings adopted by the projection device are adjustable; a stroboscopic effect can be completely eliminated; and the single-color light sources can adopt different color combination to form different color structure light. Therefore, the color structure light projection device is wide in application demand.

Owner:HUAZHONG UNIV OF SCI & TECH

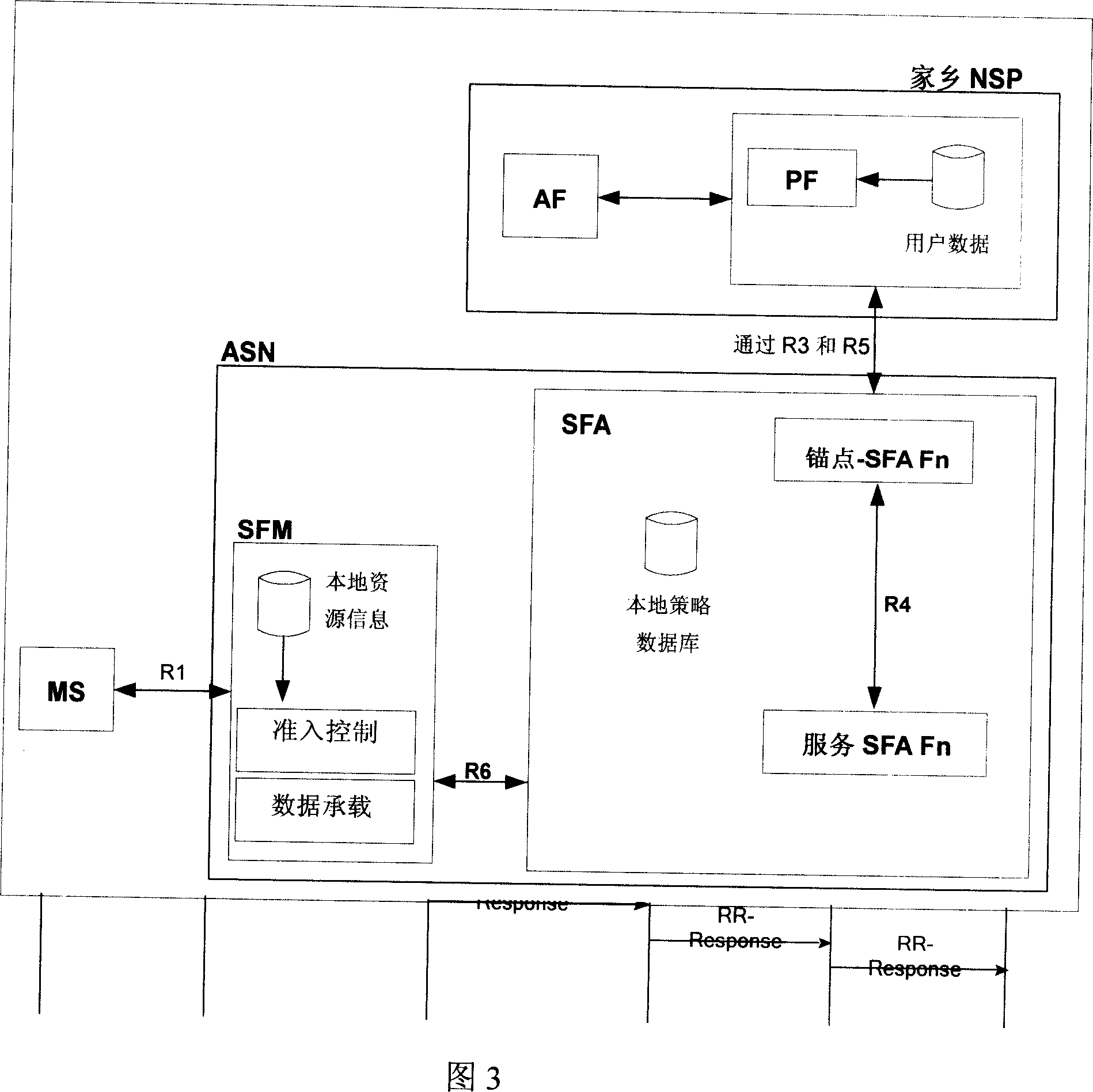

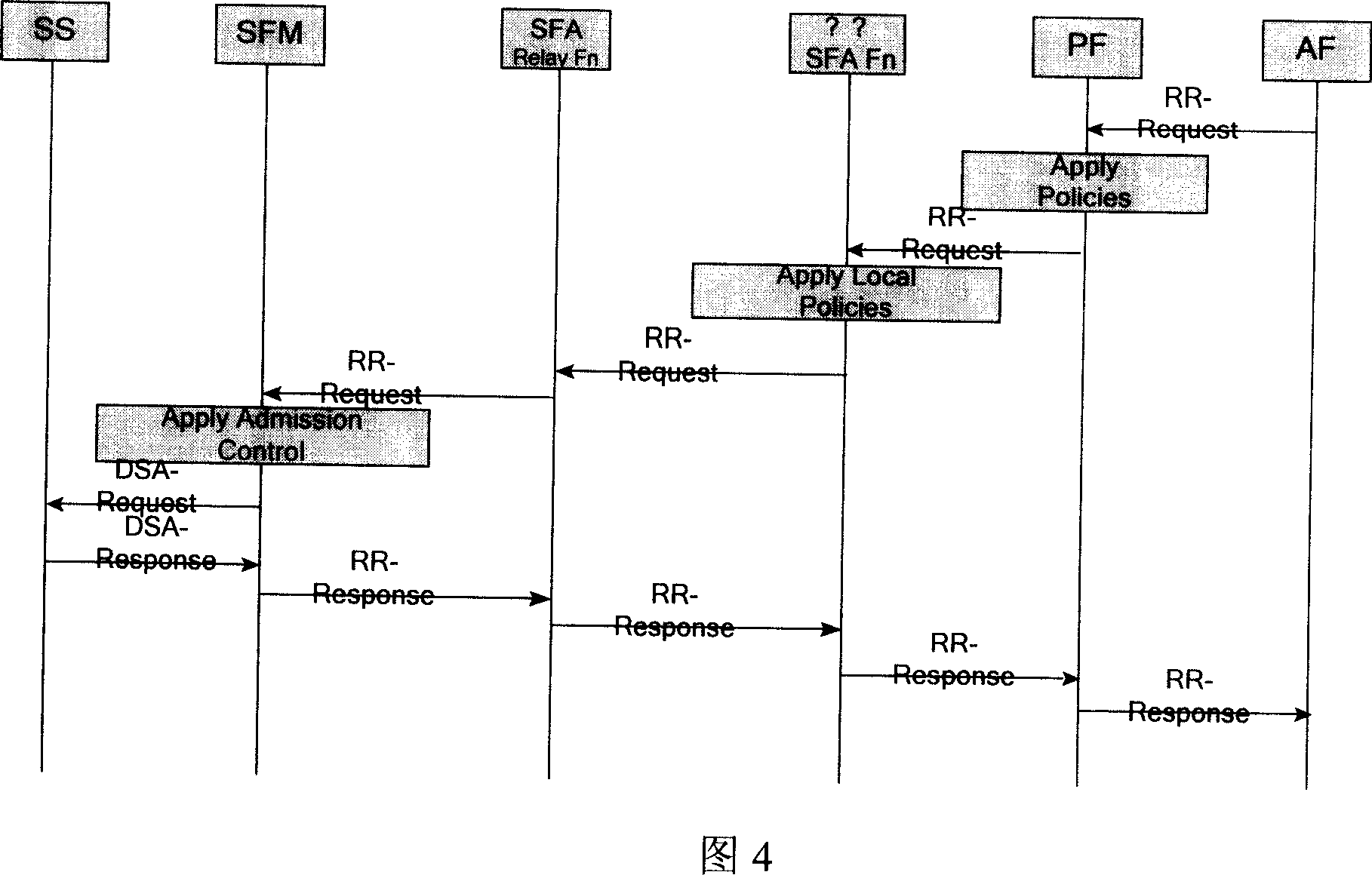

Processing method for service stream in the WiMAX multi-host system

This invention relates to one method to process network side business in Imax multi-host system, which comprises the following steps: a, sending visit G-MS business flow or AF dynamic business flow to network side; b, pertaining materials in the SFA base station for SFM require in the ASN-GW; c, requiring admission control for the materials in the SFA in station; d, establishing hollow interface channel between base station and G-MS; e, feeding back material retain results in SFA materials in the station; f, establishing channel between base station and ASN-GW.

Owner:HUAWEI TECH CO LTD

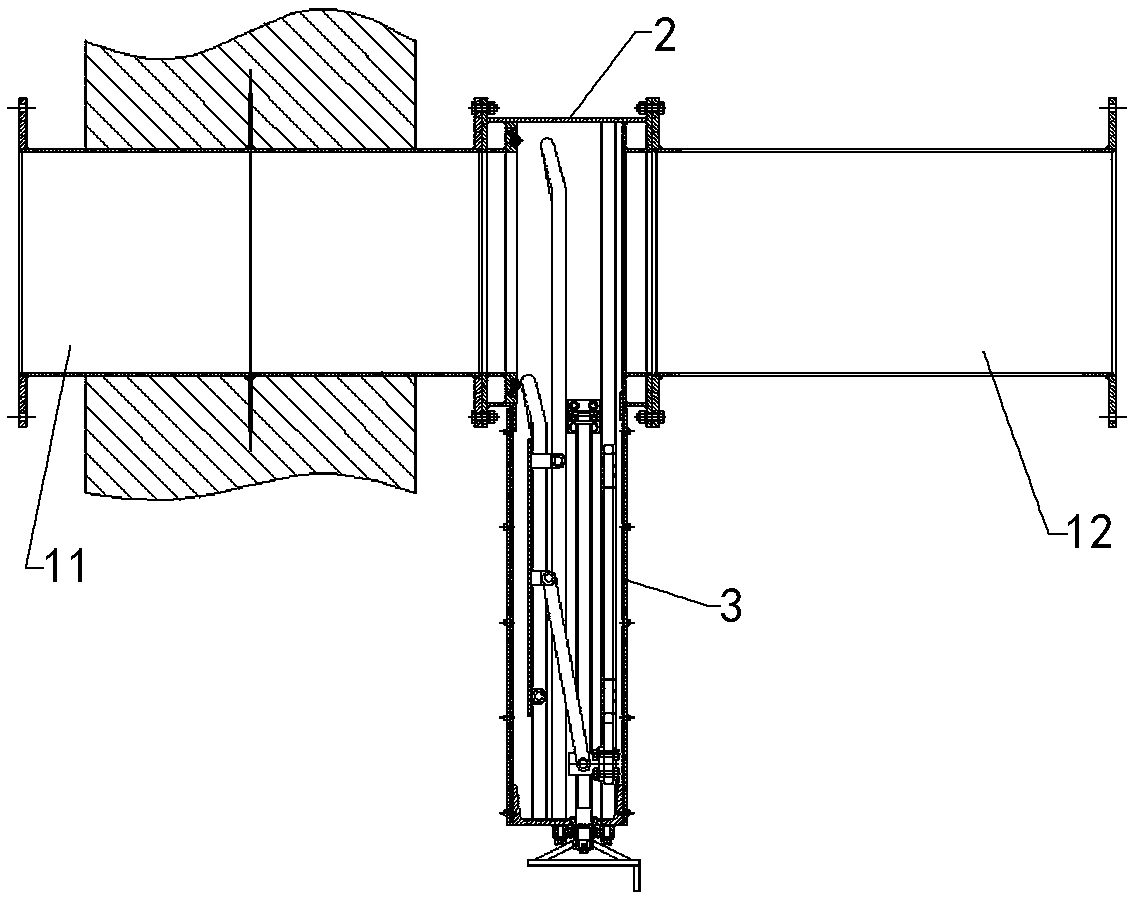

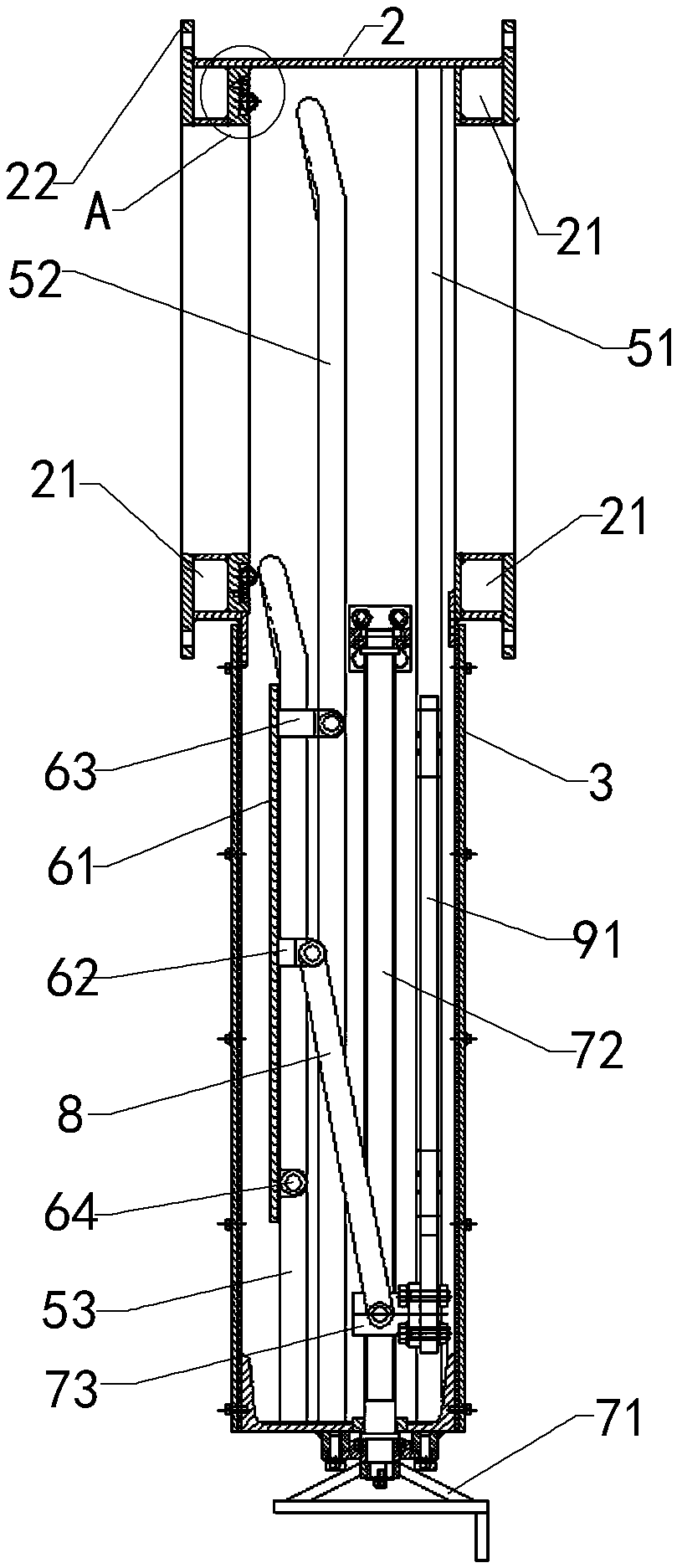

Protective sealing gate valve of through-wall air pipe and sealing method of protective sealing gate valve

PendingCN110778350ASimple structureEasy to operateMining devicesTunnel/mines ventillationStructural engineeringManufacturing engineering

The invention relates to the technical field of engineering protection, and discloses a protective sealing gate valve of a through-wall air pipe and a sealing method of the protective sealing gate valve. The protective sealing gate valve comprises a box, a sealing cover plate assembly and a driving assembly, wherein the sealing cover plate assembly is arranged in the box, and the driving assemblydrives the sealing cover plate assembly to be opened or closed; the box includes a connecting pipe body and an equipment box communicating with each other; openings of the two ends of the connecting pipe body are correspondingly hermetically connected with a through-wall pipe fitting and the air pipe, wherein the through-wall pipe fitting is pre-embedded in a wall; the equipment box is located atone side of the connecting pipe body; the sealing cover plate assembly includes a sealing gate and sliding pieces, wherein the sealing gate fits in with the orifice of the through-wall pipe fitting and the sliding pieces are located on the surface of the sealing gate; the sliding pieces are arranged in a high-position slidway or a low-position slideway at the two sides in a fit sliding manner; thesealing gate is connected with the driving assembly through a connecting rod; and the driving assembly includes a transmission assembly used for outputting power and a guide assembly used for adjusting a power direction. The protective sealing gate valve does not need to be installed and disassembled, is convenient to use, time-saving and labor-saving and has high airtightness.

Owner:CHINA INST OF BUILDING STANDARD DESIGN & RES

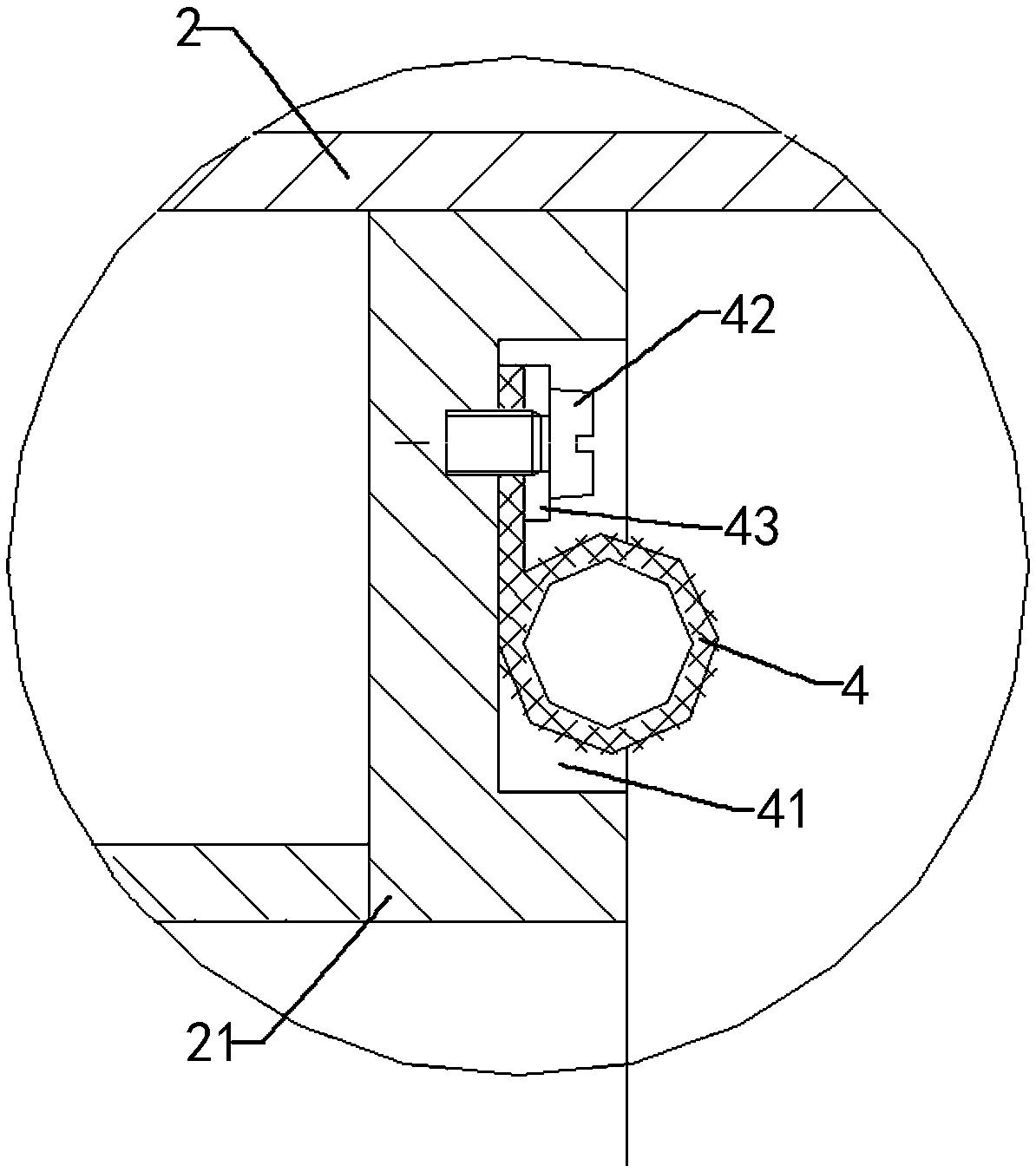

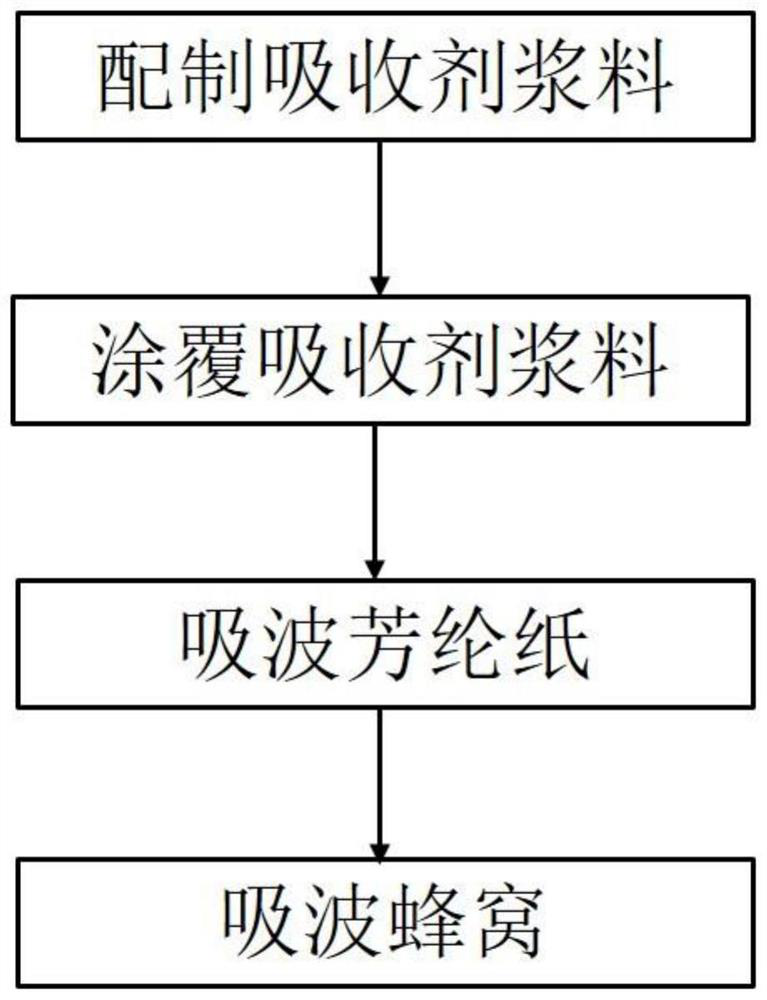

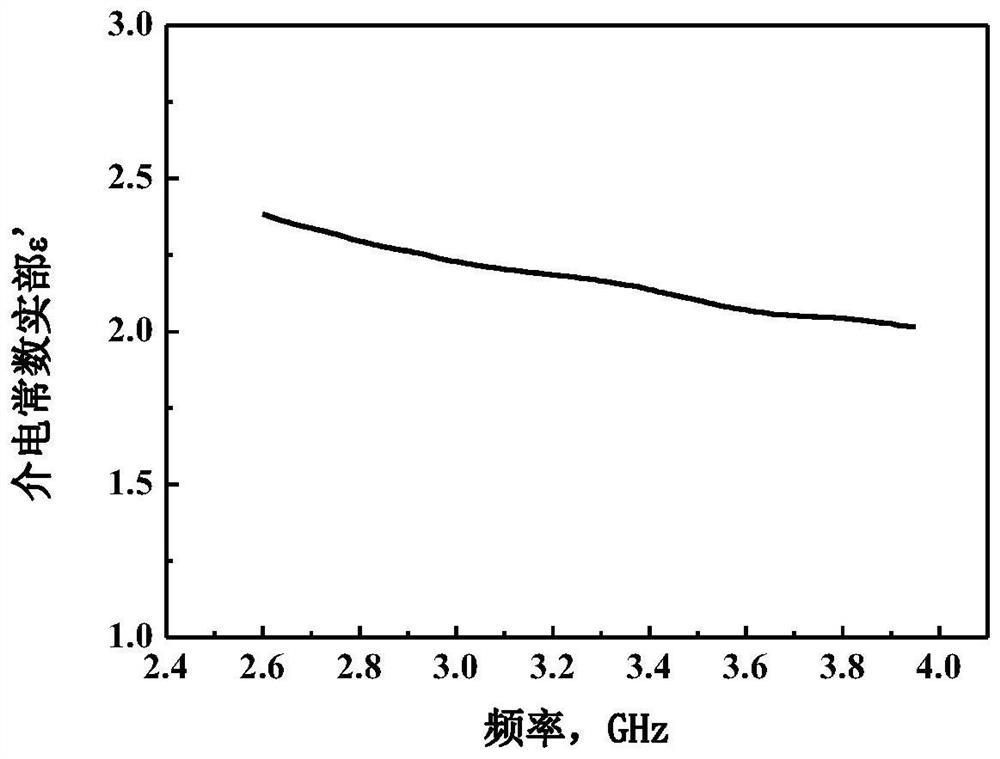

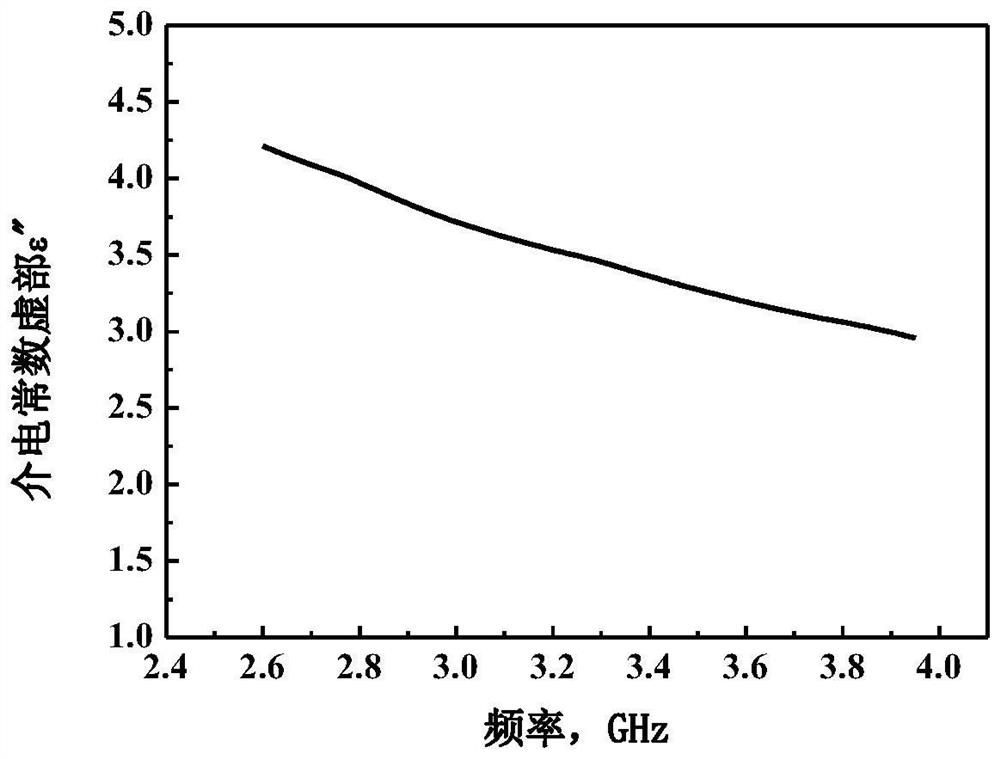

Coating type wave-absorbing aramid paper, wave-absorbing honeycomb and preparation method

PendingCN114214871APlay a role in absorbing wavesEvenly dispersedNon-fibrous pulp additionCoatings with pigmentsPolymer scienceAramid

The invention discloses coating type wave-absorbing aramid paper, a wave-absorbing honeycomb and a preparation method, and belongs to the technical field of functional materials, the coating type wave-absorbing aramid paper comprises aramid paper and a wave-absorbing layer coated on the surface of the aramid paper, the components of the wave-absorbing layer comprise an absorbent and a resin system, the thickness of the wave-absorbing layer is 0.02-0.1 mm, and the volume ratio of the absorbent to the resin system is 1: 1-1: 5. The coating type wave-absorbing aramid paper not only has high electromagnetic loss, stable electromagnetic parameters and large electromagnetic parameter regulation range, but also has good mechanical properties.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Production process for wear-resistant low temperature-resistant flame-retardant anticorrosive environment-friendly PVC rubber compound

The invention discloses a production process for a wear-resistant low temperature-resistant flame-retardant anticorrosive environment-friendly PVC rubber compound. The process comprises the following steps: weighing 30 parts of a polymerized high-molecular plasticizer, heating the polymerized high-molecular plasticizer in a container under a constant temperature in a range of 50 to 60 DGE C for 10 to 20 min, putting 100% by mass of a PVC resin with a high degree of polymerization in the container, adding 8% by mass of a calcium-zinc stabilizing agent, and carrying out middle-speed stirring for 3 to 8 min; then adding 15% by mass of a low temperature-resistant plasticizer, 6% by mass of a fire retardant, 10% by mass of a synergist and 0.8% by mass of a lubricating agent into a mixture obtained in step 1, carrying out full stirring and heating an obtained mixture to a temperature of 120 to 150 DEG C; adding 15% by mass of the low temperature-resistant plasticizer and 15% by mass of a cold resistant agent into the mixture obtained in step 2 and carrying out low-speed stirring; and putting a mixture obtained in step 3 to an extruder for extrusion. The environment-friendly PVC rubber compound prepared by using the production process has the advantages of abrasion resistance, resistance to a low temperature of -65 DEG C, resistance to a high temperature of 135 DEG C, flame retardation, resistance to corrosion by gasoline, machine oil and diesel oil, environment friendliness, no o-benzene and no phosphorus.

Owner:广东祺龙科技有限公司

Method for manufacturing logo pattern based on different color characteristics of metal or alloy

InactiveCN109280874AReasonable designEasy to implementMolten spray coatingLaser beam welding apparatusBase codeNumerical control

The invention particularly relates to a method for manufacturing a logo pattern based on different color characteristics of metal or alloy, and belongs to the field of thermal spraying and laser etching. The method for manufacturing the logo pattern based on different color characteristics of metal or alloy comprises the steps that (1) the portion, to be marked with the pattern, of the surface ofa to-be-manufactured object is cleaned, and the portion, not to be marked with the pattern, of the surface of the to-be-manufactured object is covered to be prevented from being stained; (2) the portion to be marked is sprayed through a thermal spraying device by means of the thermal spraying technique; and (3) mark contents are typeset through a computer, and a laser etching machine and a laser carving machine head are controlled through the numerical control technique to conduct etching. The method is mainly used for metal products in the oil field industry, the ship industry, the military industry, the automobile industry, the power industry and the like and can be widely used for marking articles used in severe working conditions with full-life-circle patterns. Character patterns, figure patterns, two-dimensional bar patterns and bar code patterns formed through the method are easy to recognize visually and can be recognized and input through machine-based code scanning, and backstage management is facilitated.

Owner:赵宏达

An adjustable droplet generating device

ActiveCN103454126BEasy to makeEasy to integrateComponent separationPreparing sample for investigationImplant techniqueEngineering

A capillary-based tunable droplet generation device. The generating device can be driven by positive pressure or negative pressure to generate nanoliter to picoliter-scale droplets; compared with the traditional microfluidic chip droplet generating device, the generating device does not require microfluidic preparation process and is easy to manufacture. The size of the generated droplets can be adjusted in multiple dimensions. And the droplet generation technology can be seamlessly embedded into the existing biological detection process.

Owner:UNIV OF SCI & TECH OF CHINA

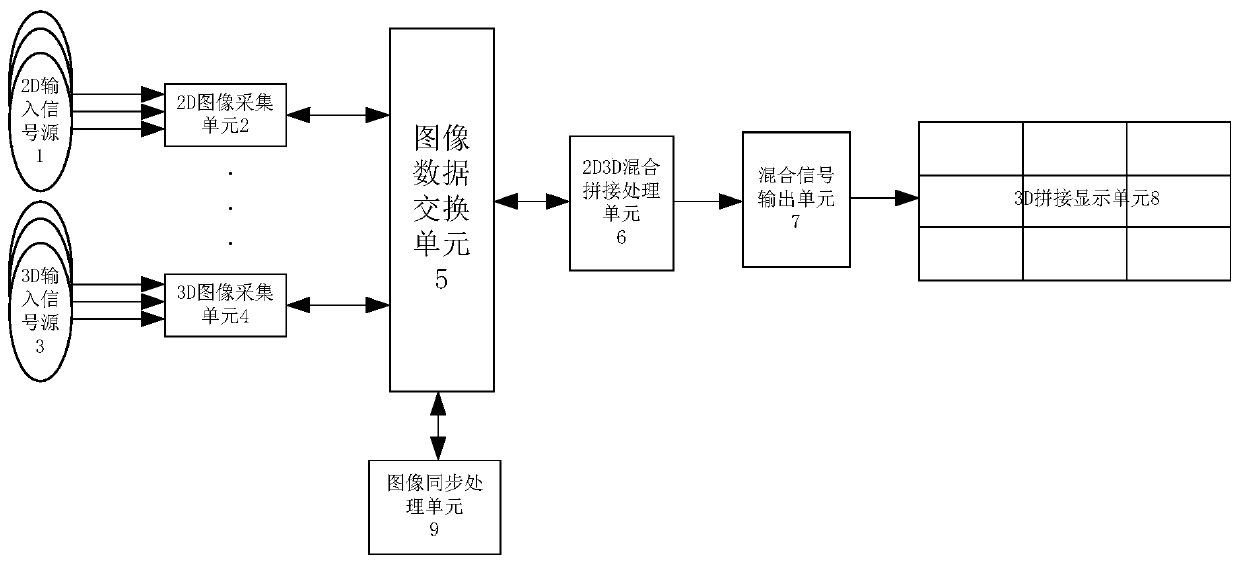

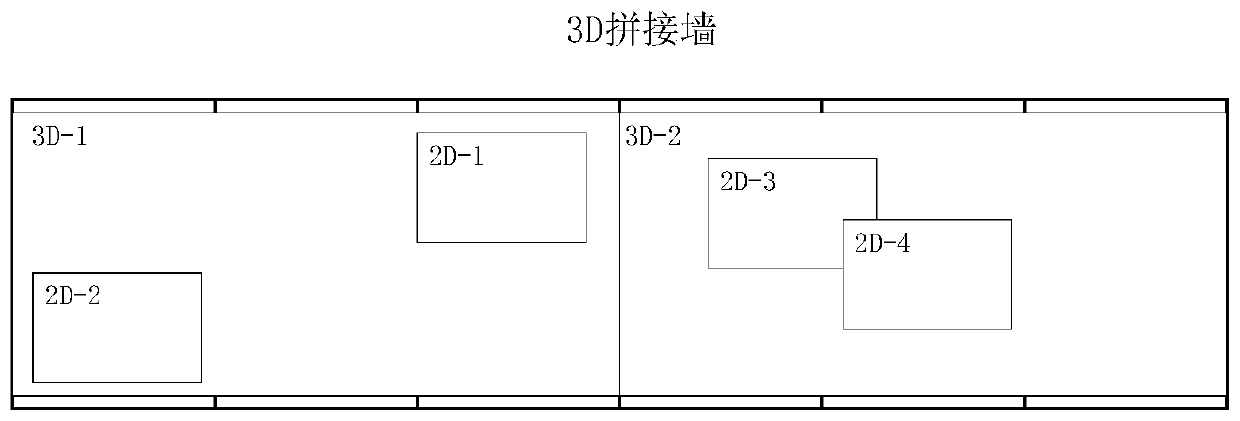

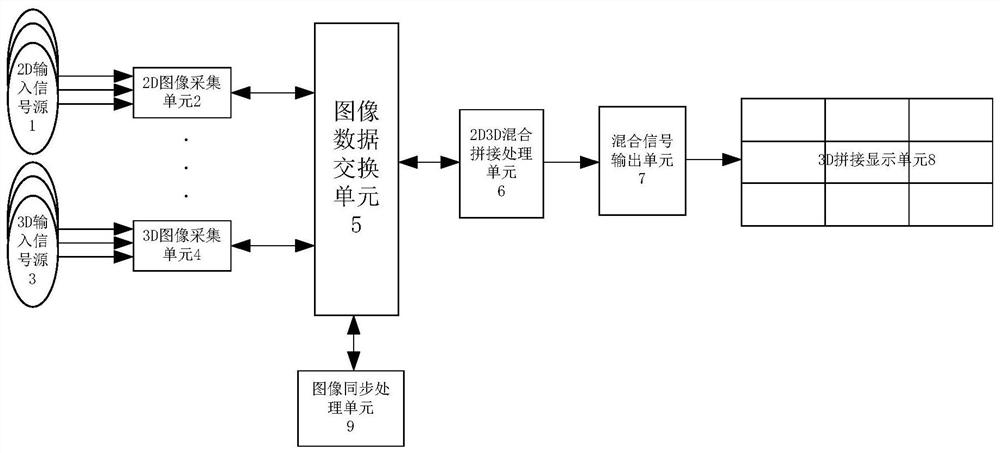

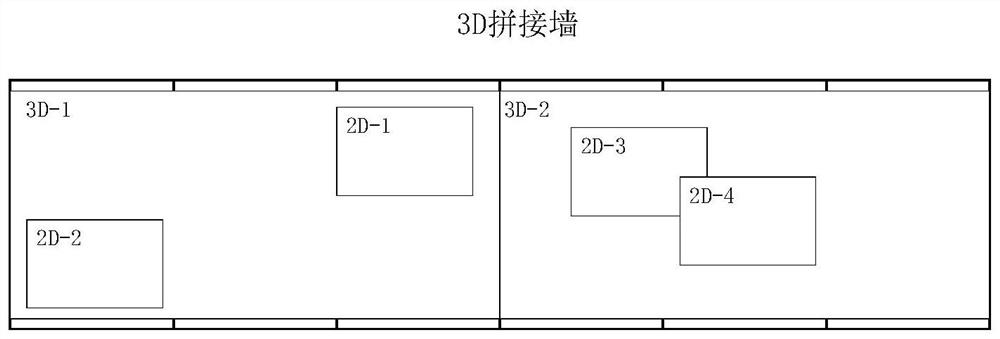

2D-3D image hybrid splicing system

ActiveCN110996090AImprove work efficiencyImprove scalabilitySteroscopic systemsPattern recognitionImaging processing

The invention belongs to the technical field of image processing, and particularly relates to a 2D-3D image hybrid splicing system. The system comprises a 2D image signal acquisition unit, a 3D imagesignal acquisition unit, an image synchronization processing unit, an image data exchange unit, a 2D and 3D hybrid splicing processing unit, a hybrid signal output unit and a 3D splicing display unit.Any plurality of 2D images and 3D images can be subjected to image hybrid splicing processing, and are finally synchronously displayed on one group of display units; therefore, a user can watch a plurality of 3D image signals and a plurality of 2D image signals at the same time, and the efficiency of obtaining image information by the user is improved; according to the system, the problems that atraditional 3D image display system is single in function, tedious in signal switching operation and the like are solved, and the working efficiency and the use experience of a user are greatly improved.

Owner:上海晨驭信息科技有限公司

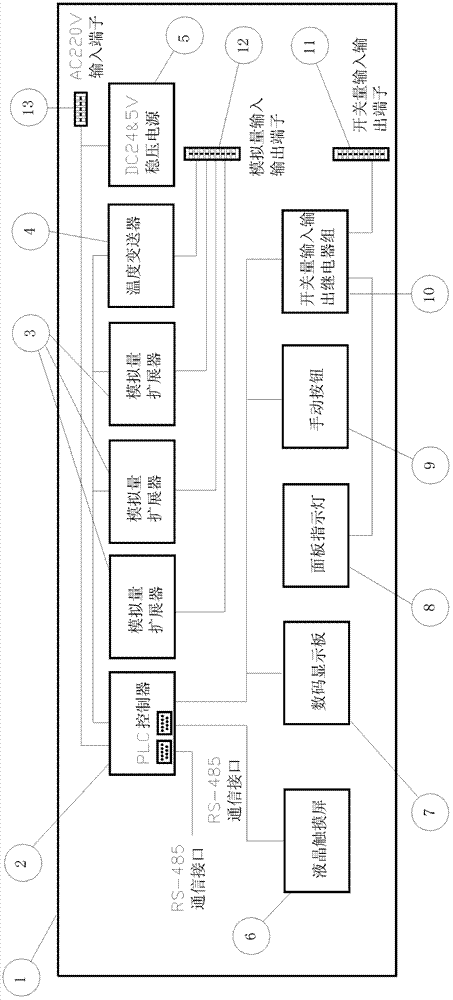

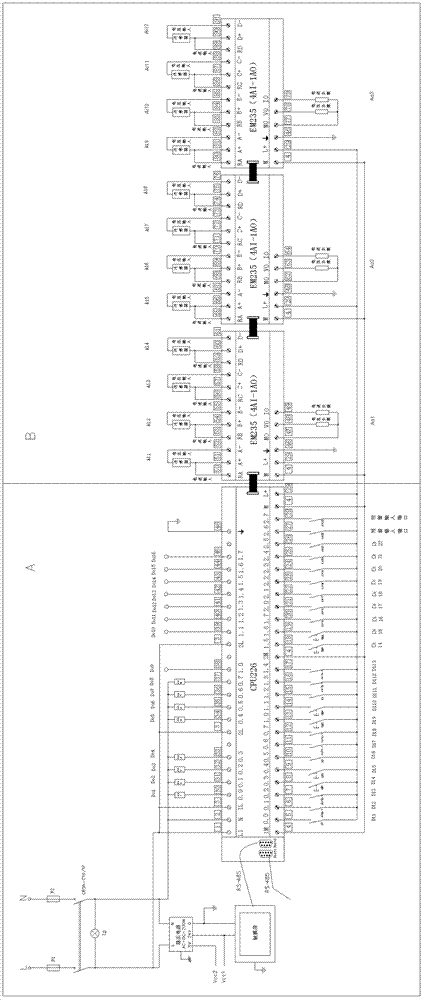

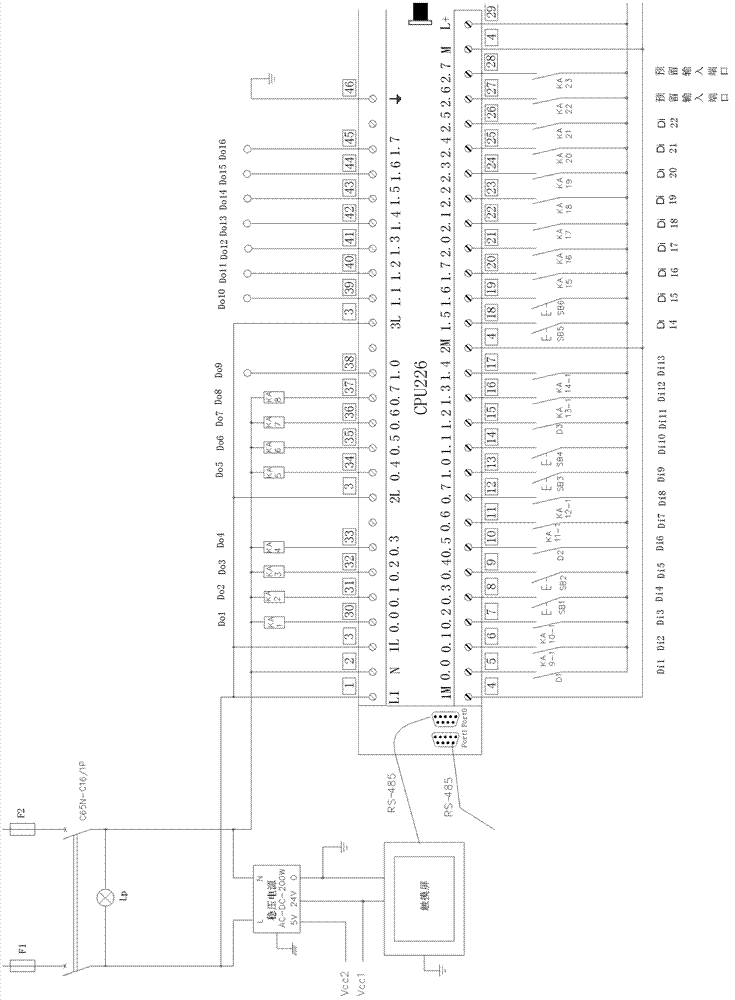

Multifunctional hydraulic equilibrium automatic control and regulation device

ActiveCN102323789BGood hydraulic balance effectLow investment costProgramme control in sequence/logic controllersAutomatic controlHuman–machine interface

The invention relates to a multifunctional hydraulic equilibrium automatic control and regulation device which comprises a control and regulation box, wherein a human-machine interface is arranged on a panel of the control and regulation box, a PLC (Programmable Logic Controller) is arranged in the control and regulation box and is electrically connected with the human-machine interface through a communication interface. The multifunctional hydraulic equilibrium automatic control and regulation device also comprises an analog quantity expander, an analog quantity input output terminal, a switching input output relay set and a switching input output terminal; and the valve opening of an electric valve is automatically controlled by combining with a self-checking operation process and an automatic control and regulation operation process through establishing a communication connection of the human-machine interface and the PLC and defining a port. According to the invention, common heating construction technicists carry out setting and selection on the human-machine interface according to the guidance of care instructions, opening of an electric butterfly valve or an electric regulating valve is automatically controlled and regulated easily after operation parameters of a controlled valve combination are set, low investment cost is realized and wide application demands are met.

Owner:深圳市物有所智科技有限公司

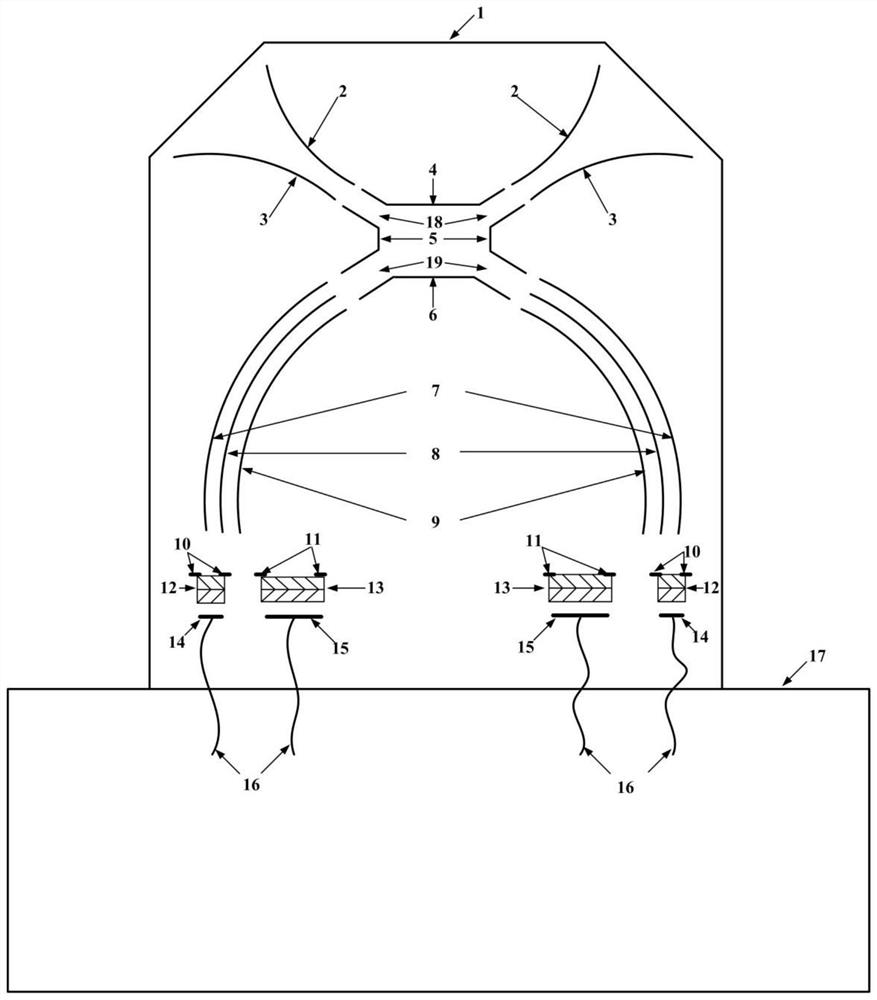

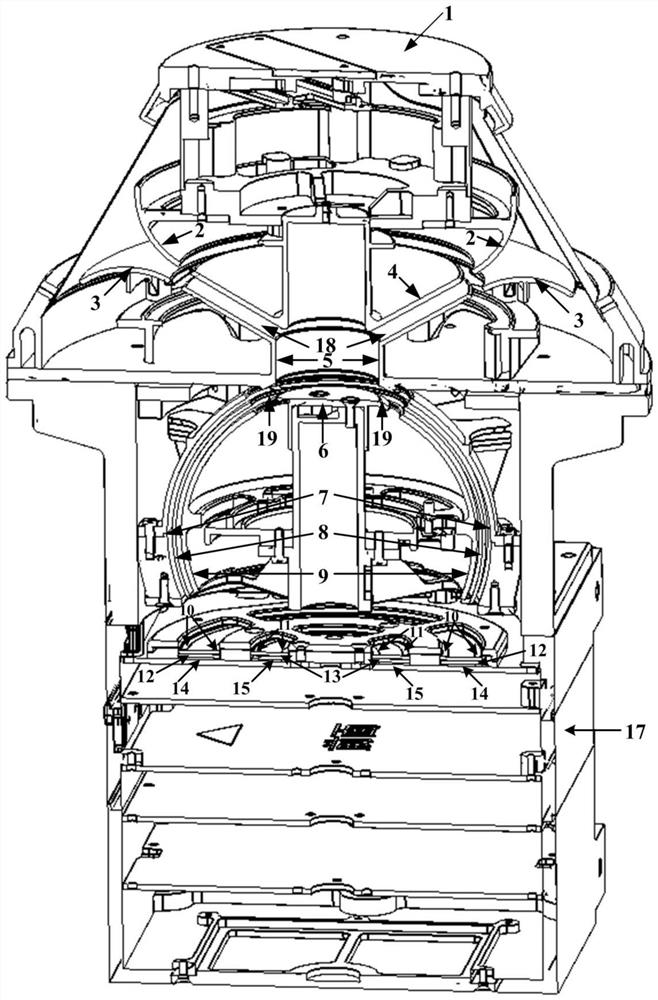

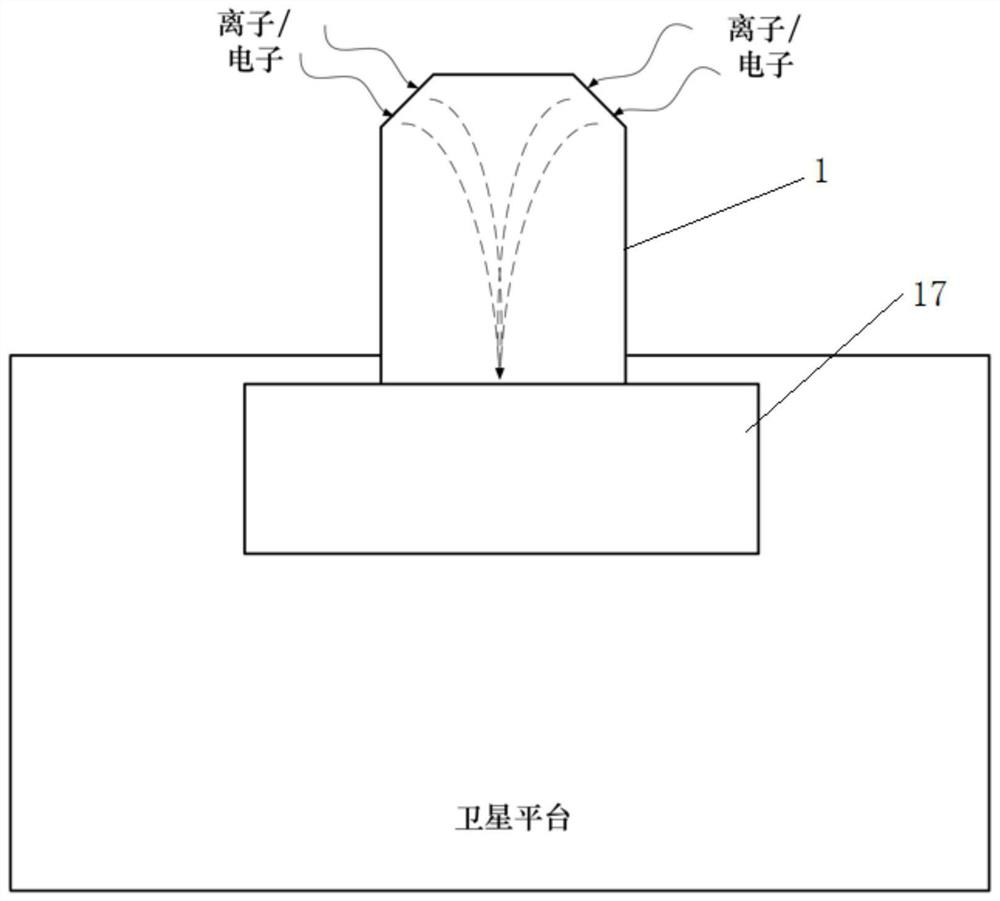

Two-channel electrostatic analyzer capable of synchronously measuring ions and electrons

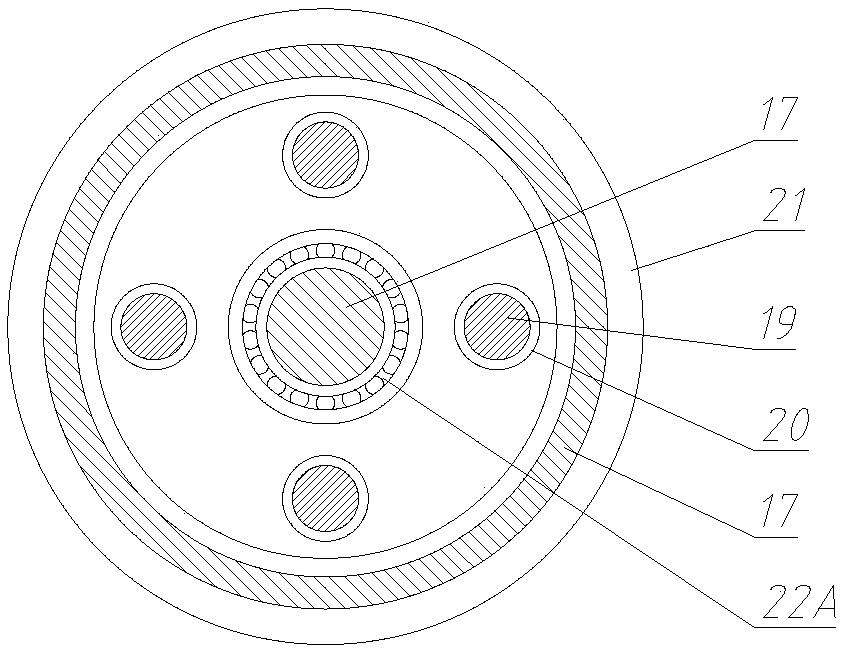

PendingCN112799120AReduced weight and power requirementsReduce weightX/gamma/cosmic radiation measurmentEngineeringElectronics

The invention relates to the technical field of space physics and space environment detection, in particular to a two-channel electrostatic analyzer for ion and electron synchronous measurement, which comprises an electrostatic deflection device, a track guide device, a two-channel hemispherical electrostatic analyzer, a separation electrode device, a signal pre-amplification device, an electronics processor (17) and a device shell (1). The device shell (1) is arranged on the electronics processor (17), and the electrostatic deflection device, the track guide device, the dual-channel hemispherical electrostatic analyzer, the separation electrode device and the signal pre-amplification device are arranged in the device shell (1). A track guiding device is arranged below the electrostatic deflection device, and the electrostatic deflection device is connected with the track guiding device; the dual-channel hemispherical electrostatic analyzer is arranged below the track guiding device and is connected with the track guiding device; and the separation electrode device and the signal pre-amplification device are sequentially arranged below the two-channel hemispherical electrostatic analyzer and are connected with the electronics processor through a cable.

Owner:NAT SPACE SCI CENT CAS

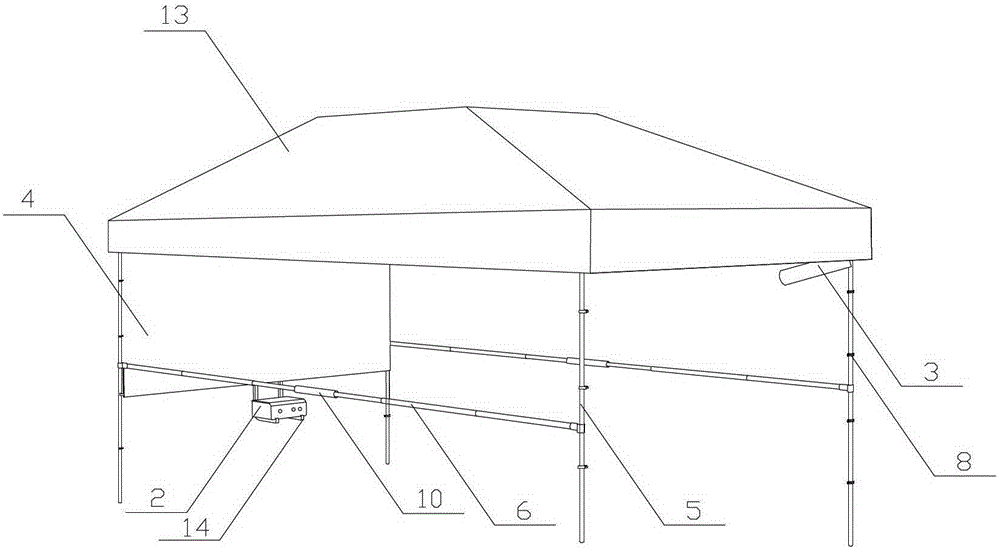

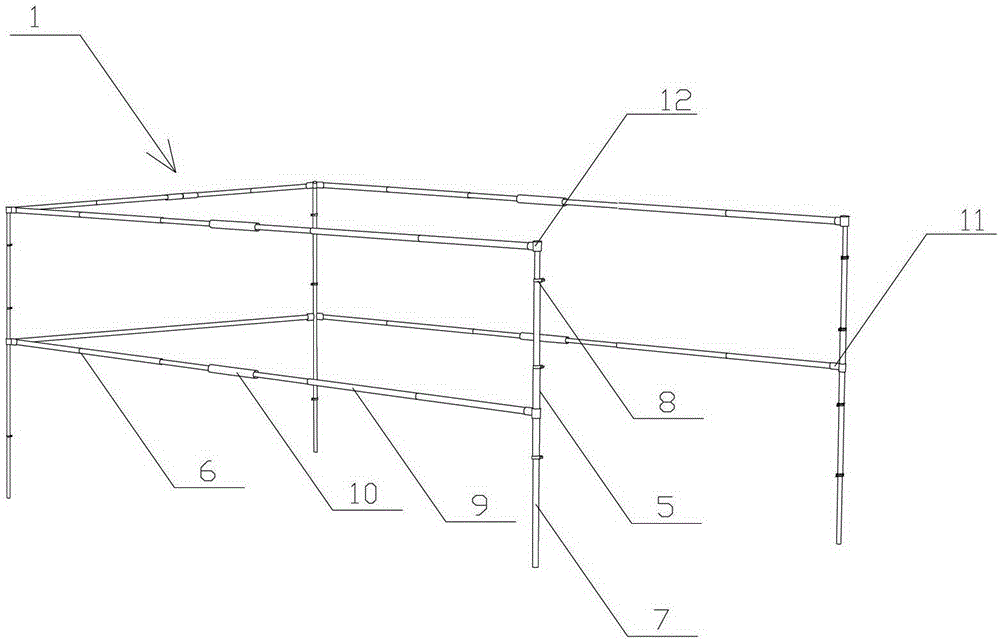

Mobile somatosensory interactive platform

InactiveCN103386189ATo achieve the purpose of sports and entertainmentAdd funVideo gamesTheatresSomatosensory systemComputer science

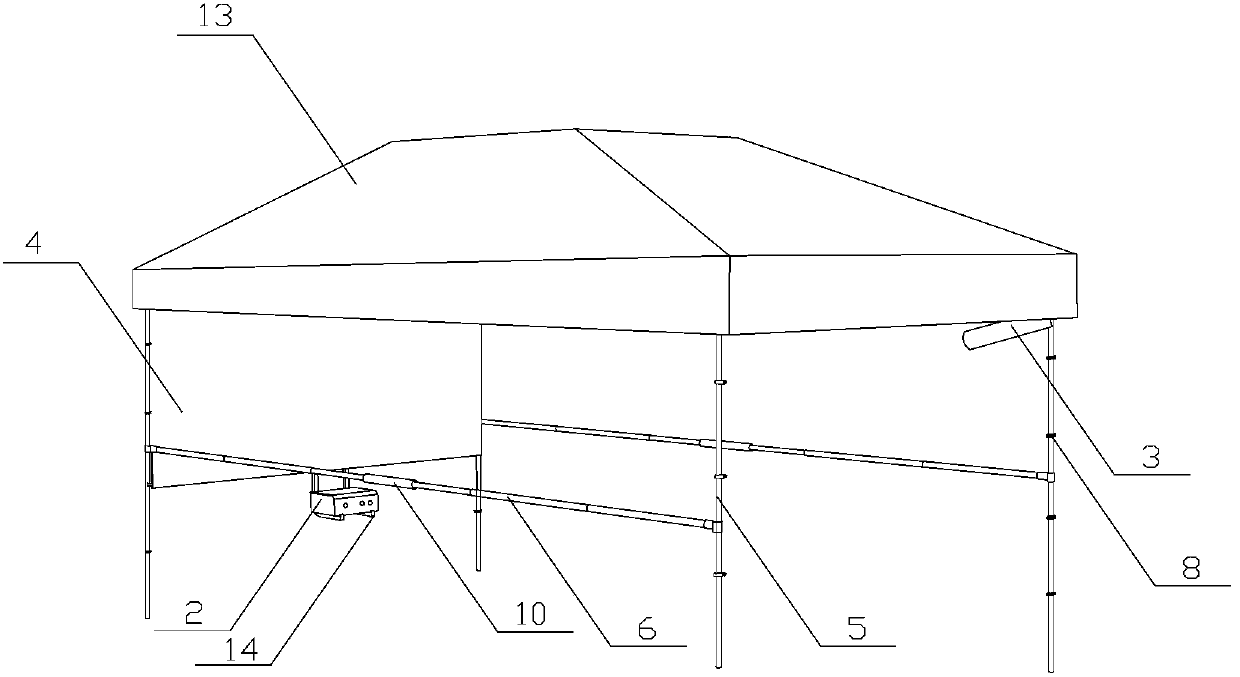

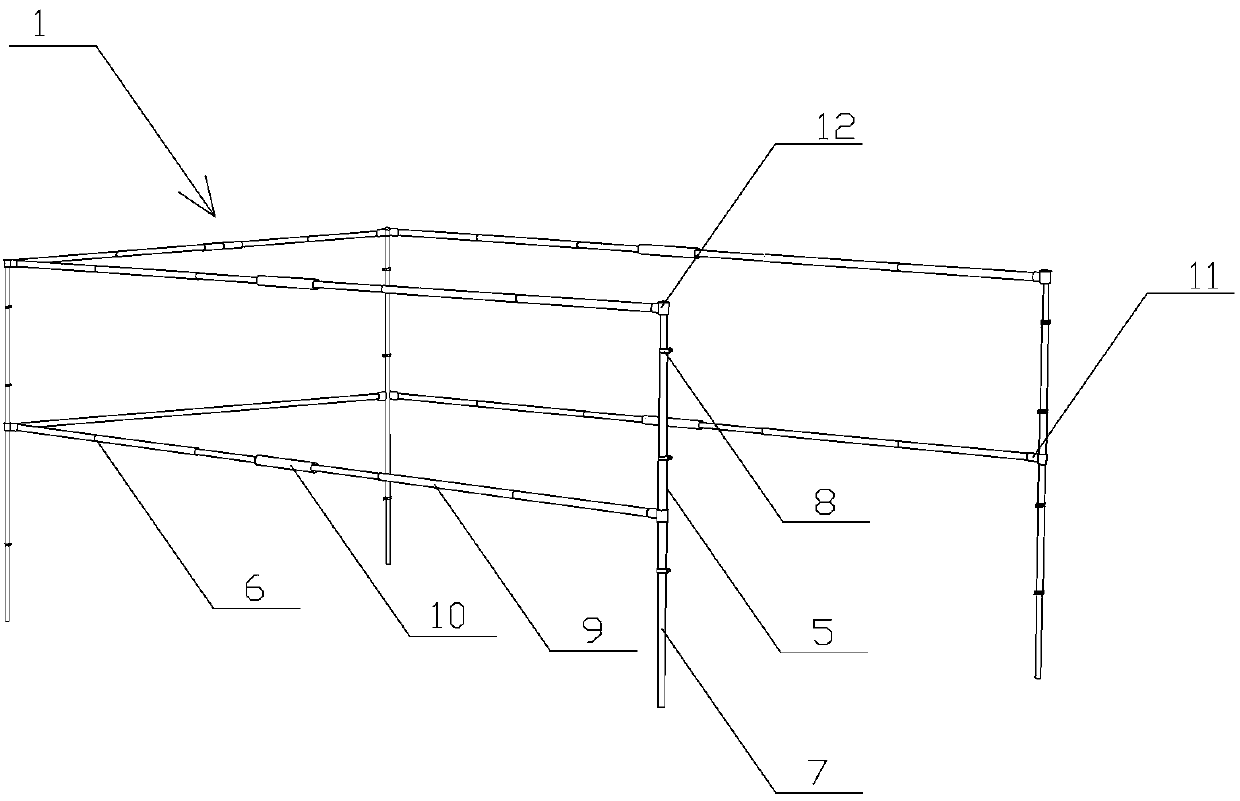

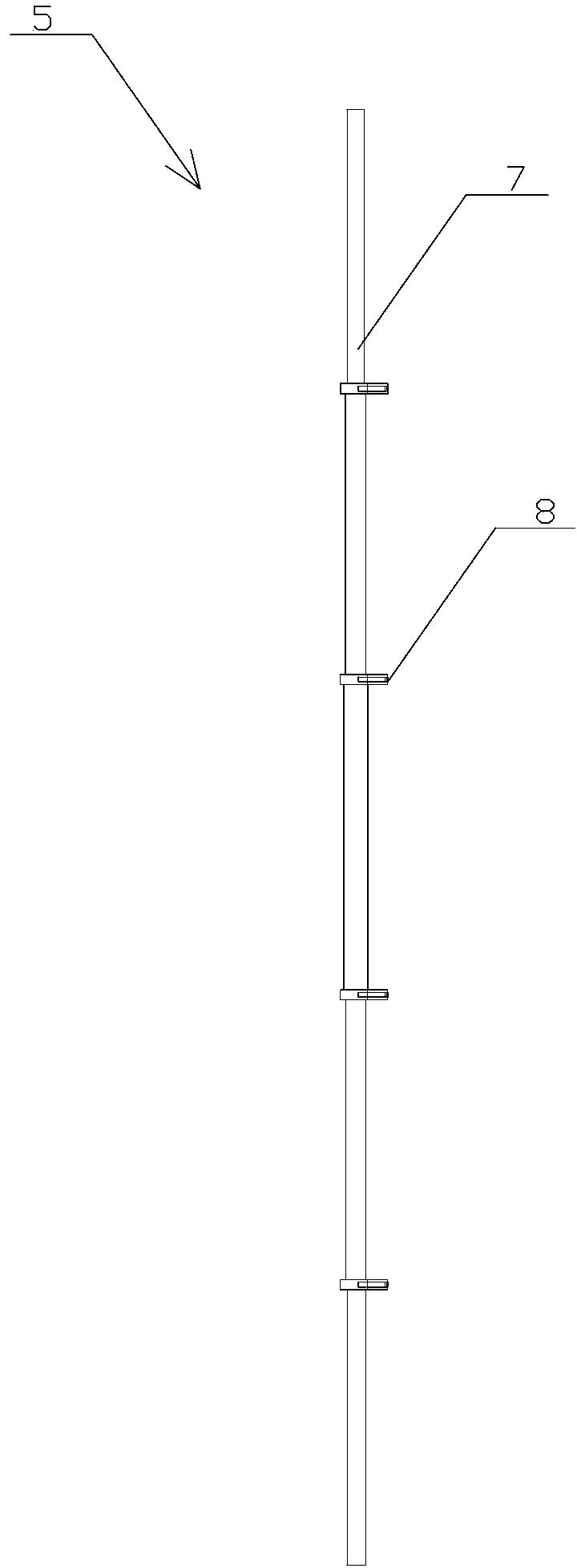

The invention discloses a mobile somatosensory interactive platform which comprises a supporting skeleton, a somatosensory interaction machine, a projector and a projection curtain. An active space is surrounded by the supporting skeleton; the projection curtain is hung at one side of the supporting skeleton; the projector is arranged opposite to the projection curtain; and the somatosensory interaction machine is connected with the projector. According to the invention, contents of the somatosensory interaction machine are projected onto the projection curtain by the projector, and by setting software inside the somatosensory interaction machine, a user can carry out recreational activities according to the contents on the projection curtain; a small-scale cinema and outdoor advertising publicity scheme is also provided; the supporting skeleton is of a removable folding structure, so that recreational activities are not limited by places in short time, and meanwhile, the number and lengths of supporting skeleton assemblies can be regulated as required to meet the requirements on different sizes of spaces; and moreover, the supporting skeleton can be of a shape of triangle, rectangle and the like.

Owner:浙江恩佐瑞视科技有限公司

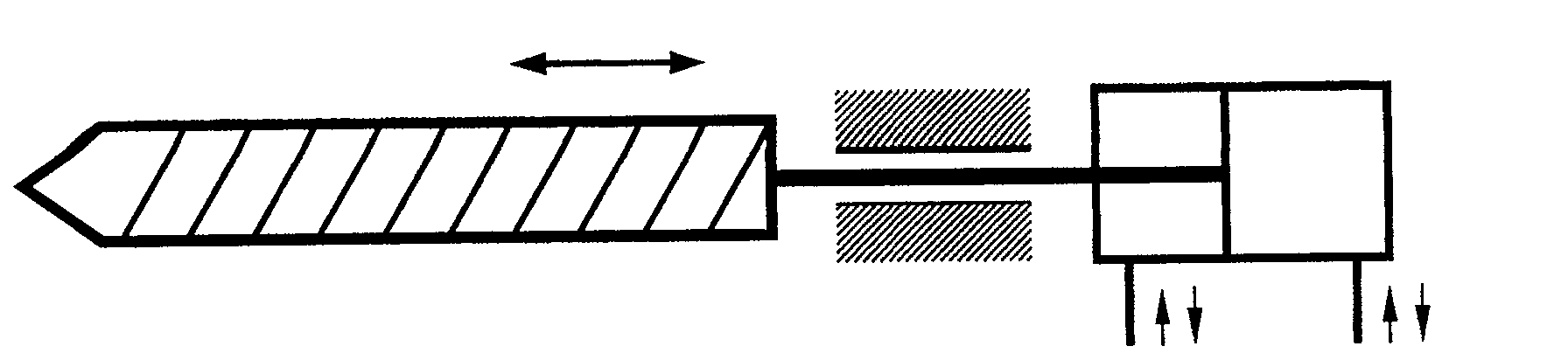

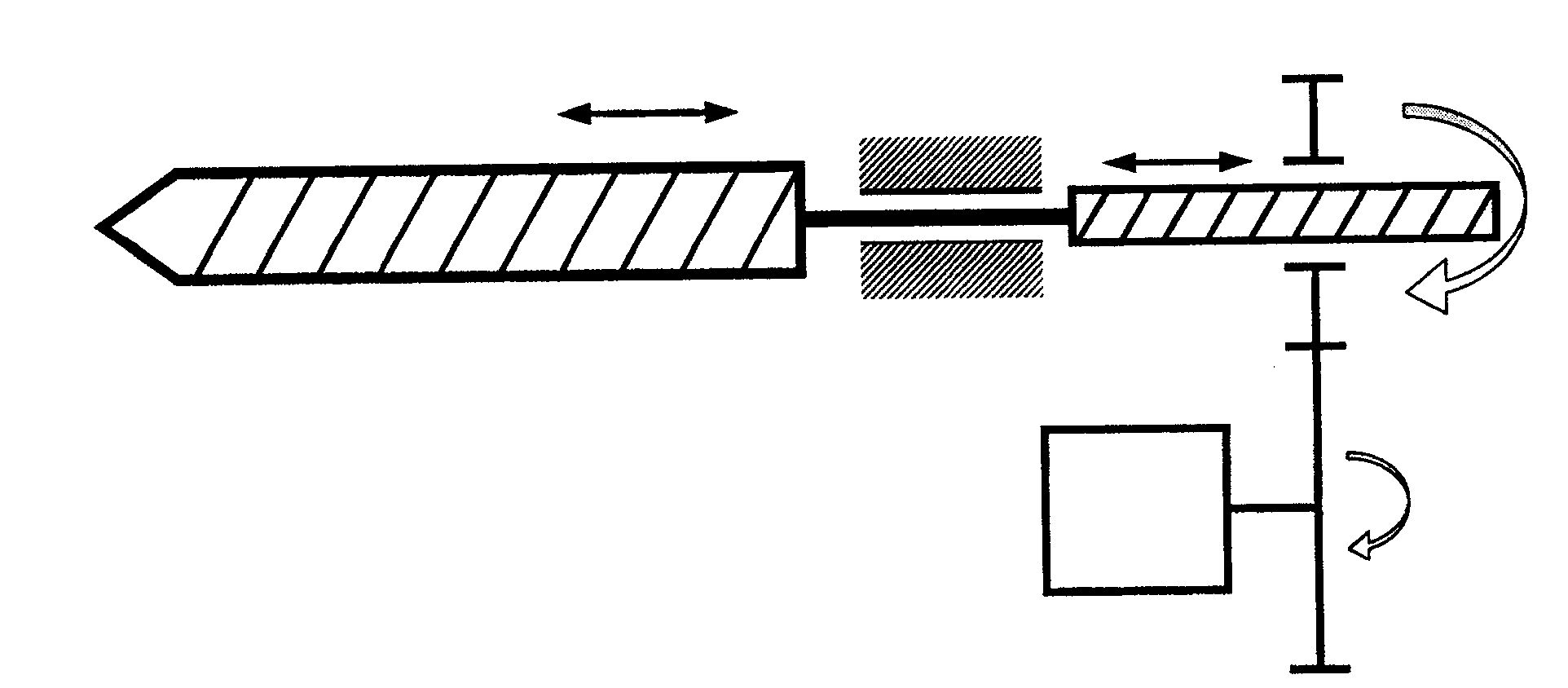

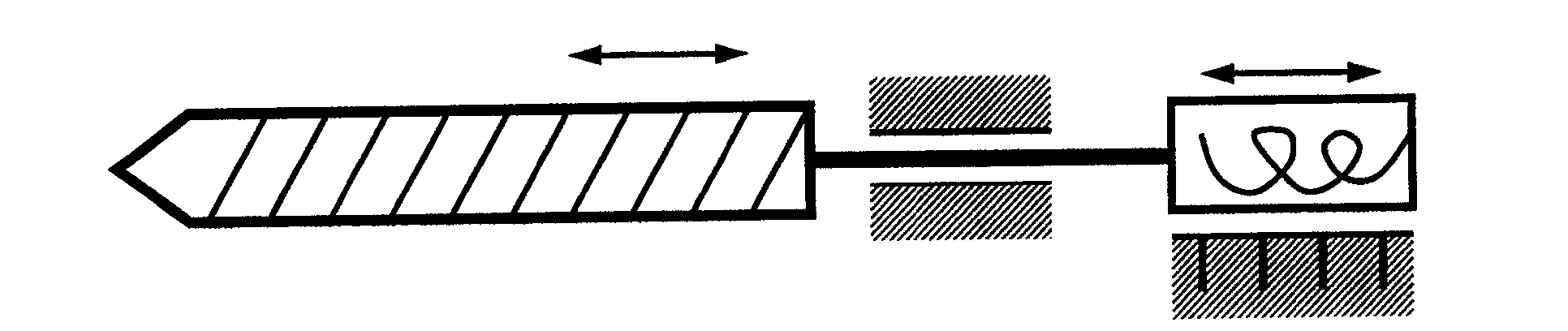

Dynamic injecting system of injection moulder, and its vibration injecting method

The invention provides a dynamic injection system for an injection molding machine, which includes an injection barrel, a screw, and an injection drive mechanism. The screw extends into the injection barrel. connected; the crank vibrating injection mechanism includes several crank drive assemblies, the several crank drive assemblies are arranged in phases with each other, and are connected with the synchronous drive components. The vibration injection method realized by the dynamic injection system of the injection molding machine is to inject the material melts separately by the crank vibration injection mechanism with a certain phase, and then mix the material melts together before injecting, directly introducing the vibration effect into the material melts. The present invention introduces vibration effect without additional vibration generating device in the injection process, so that the physical properties of the product and the energy-saving effect of the molding process are significantly improved, and it has the advantages of simple and reasonable structure, low cost, convenient control, and easy large-scale promotion Advantages of using.

Owner:佛山市顺德区震德塑料机械有限公司

A mobile somatosensory interactive platform

InactiveCN103386189BTo achieve the purpose of sports and entertainmentAdd funVideo gamesTheatresSomatosensory systemComputer science

Owner:浙江恩佐瑞视科技有限公司

A self-focusing vertical cavity surface emitting laser

ActiveCN103178443BSimple preparation processGood repeatabilityLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserManufacturing technology

The invention discloses a vertical-cavity surface-emitting laser capable of automatically focusing, and belongs to the field of semiconductor lasers. The vertical-cavity surface-emitting laser capable of automatically focusing comprises a P-type DBR (distributed Bragg reflective) layer, an active layer, an N-type DBR layer, a lining layer, a lower electrode wrapped on the P-type DBR layer, and an upper electrode laid on the lining layer. A part, covered on a light emitting window, of the upper electrode is shaped in a concentric ring or a structure with unequally spaced grid bars or crossed grid bars, the upper electrode with the above structure can be formed via the lift-off technology by one step, with the upper electrode, output laser light beams can be focused into a point light spot, or a linear light spot or a cross light spot without additionally adding a light beam shaping device, laser power intensity is greatly enhanced partly, and wide application requirements are met. The vertical-cavity surface-emitting laser capable of automatically focusing is simple in manufacturing technology, good in repeatability and easy to popularize.

Owner:长春中科长光时空光电技术有限公司

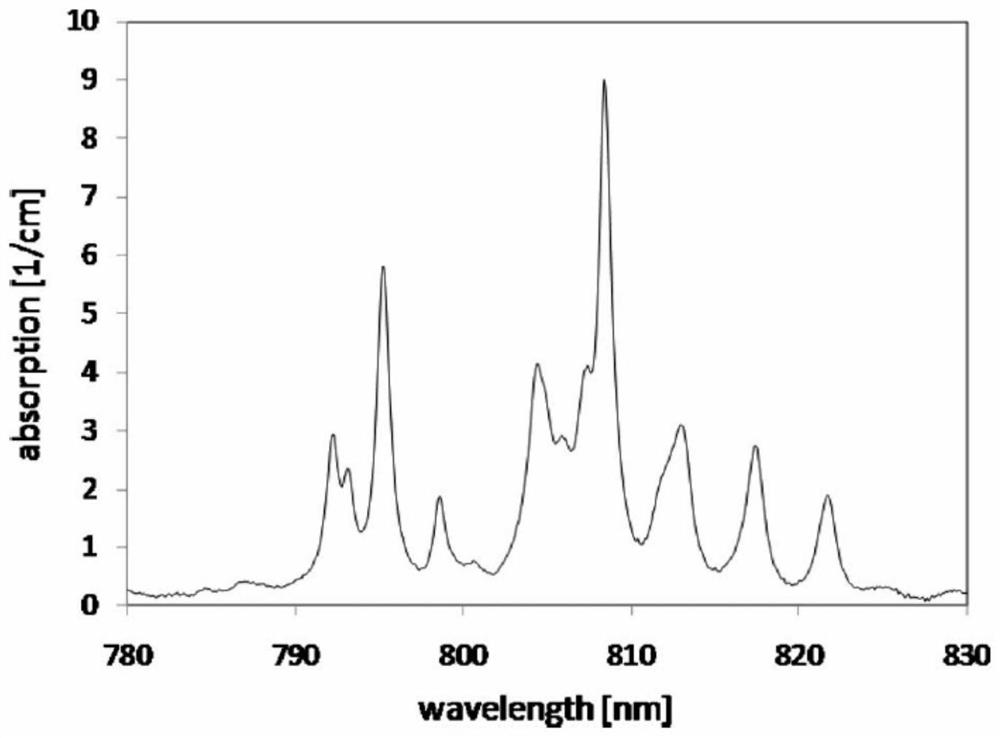

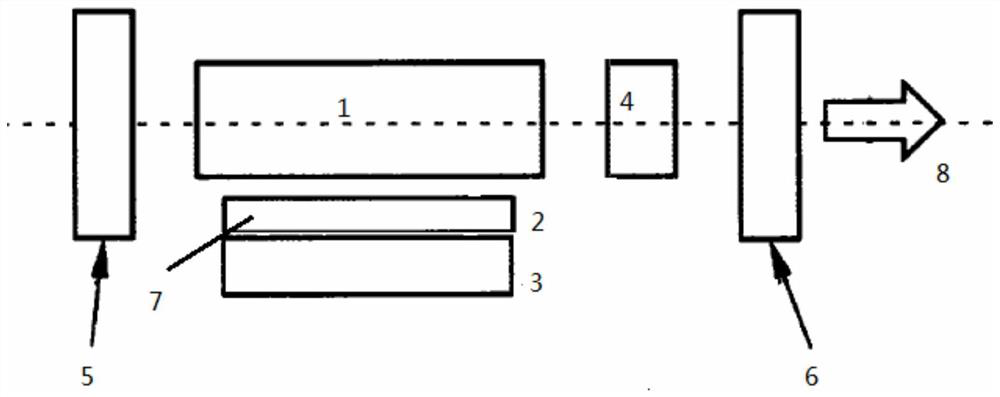

Dual-temperature working all-solid-state Nd: YAG laser

PendingCN112821174ASmall heating spanShorten warm-up timeLaser constructional detailsActive medium shape and constructionResonant cavityLaser ranging

The invention discloses a dual-temperature working all-solid-state Nd: YAG laser, which comprises an Nd: YAG laser gain medium, a pumping source, a heater, a Q-switching device and a laser resonant cavity mirror, the laser resonant cavity mirror, the Nd: YAG laser gain medium and the Q-switched device form a resonant cavity; and the pumping source pumps laser into the resonant cavity, and the heater heats the pumping source. Compared with the previous high-temperature work, the two-stage temperature control method has the advantages that the temperature rise span is smaller, the required preheating time is greatly shortened, and the two-stage temperature control method is very useful in many applications, and particularly has wide application requirements on military laser ranging, laser irradiator, laser ranging / irradiation all-in-one machines and the like.

Owner:SOUTH WEST INST OF TECHN PHYSICS

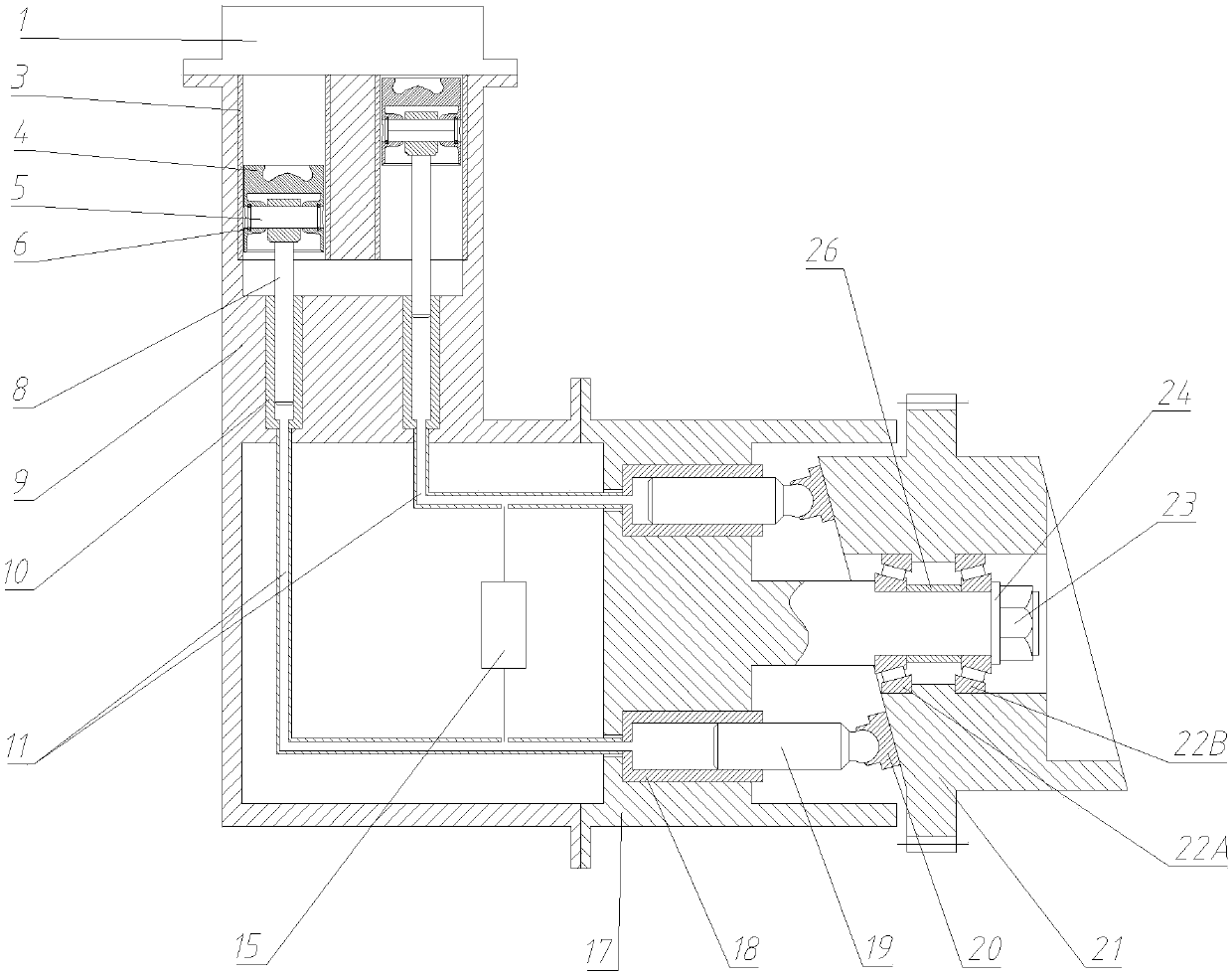

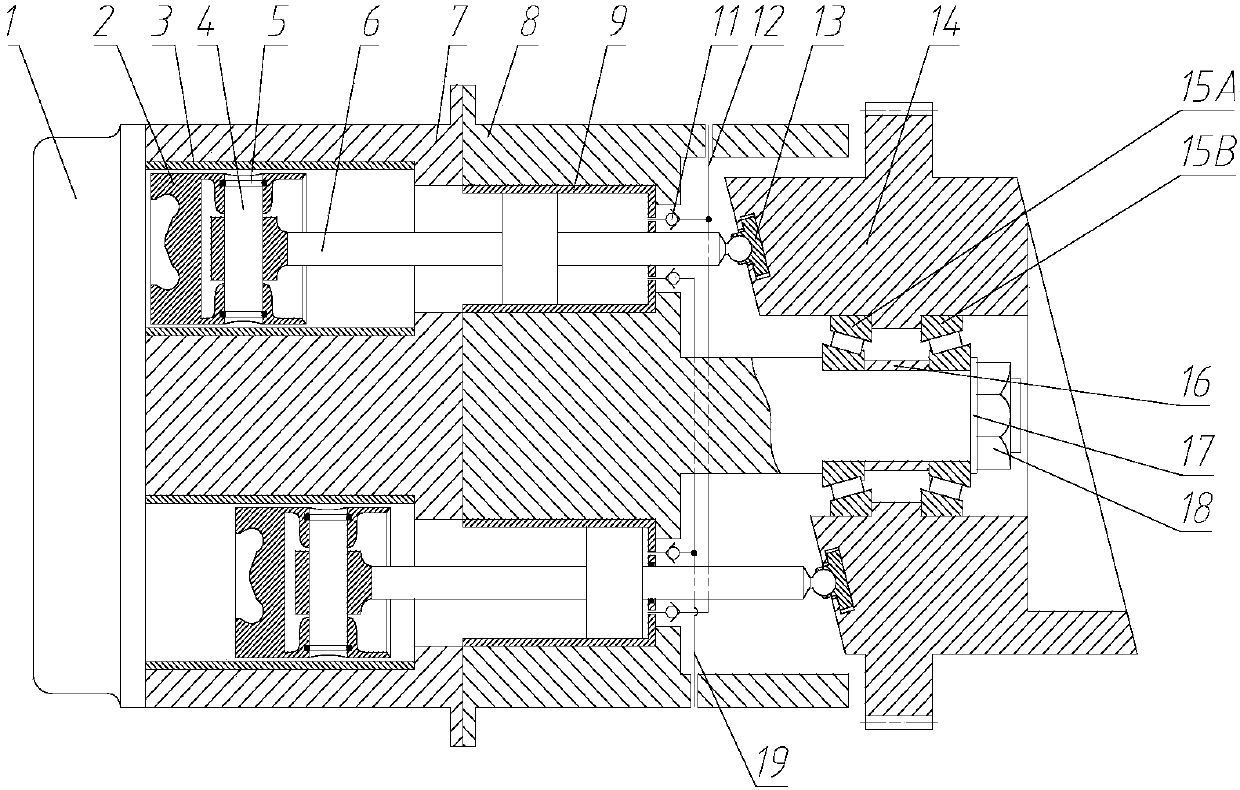

Crankshaft-free hydraulic transmission engine

ActiveCN107587940AReduce scratchesCompact structureReciprocating piston enginesMechanical energyEngineering

The invention discloses a crankshaft-free hydraulic transmission engine and relates to the field of internal combustion engine engineering. The crankshaft-free hydraulic transmission engine comprisesa cylinder body, and further comprises at least two input parts, a transmission part and a transmission part arranged in the cylinder body, wherein each input part comprises a piston, a cylinder liner, a piston pin, elastic check rings and a pressure plunger, wherein the piston pin is in sliding connection with the piston, and both ends of the piston pin are provided with the elastic check rings mounted in mounting holes of the piston. An output part comprises a power plunger, a sliding shoe and a swash plate flywheel. The transmission part comprises a pressure cylinder arranged in the cylinder body, a power cylinder arranged in the cylinder body and an oil supplementing system arranged in the cylinder body. The crankshaft-free hydraulic transmission engine has the advantages that heat energy is converted into mechanical energy, the structure is compact, the feedback is timely, the transmission is more steady, the industrialization prospect is good, and the application demand is wide;and the scratching to the cylinder liner caused by the movement of the piston pin in the piston is reduced.

Owner:QINGDAO UNIV

Oblique disk mechanism mechanical-hydraulic dual power engine

ActiveCN107605598ACompact structureShort energy transfer routeMachines/enginesCombustionMechanical energy

The invention relates to the technical field of energy conversion devices, in particular to an oblique disk mechanism mechanical-hydraulic dual power engine. According to the oblique disk mechanism mechanical-hydraulic dual power engine, running unevenness is low, the structure is compact, the cost is low, internal shunt can be achieved, combustion heat energy is directly converted into mechanicalenergy and hydraulic energy, and mechanical and hydraulic dual power can be output. The oblique disk mechanism mechanical-hydraulic dual power engine omits a crank linkage mechanism of a traditionalengine, the structure is compact, the energy converting and transferring route is short, the work is smooth and stable, mechanical or hydraulic powers can be output, and the oblique disk mechanism mechanical-hydraulic dual power engine has good industrialization prospect and wide application demands.

Owner:QINGDAO UNIV

A 2d-3d image hybrid stitching system

ActiveCN110996090BImprove work efficiencyImprove scalabilitySteroscopic systemsPattern recognitionImaging processing

The invention belongs to the technical field of image processing, and particularly relates to a 2D-3D image hybrid splicing system. The system comprises a 2D image signal acquisition unit, a 3D imagesignal acquisition unit, an image synchronization processing unit, an image data exchange unit, a 2D and 3D hybrid splicing processing unit, a hybrid signal output unit and a 3D splicing display unit.Any plurality of 2D images and 3D images can be subjected to image hybrid splicing processing, and are finally synchronously displayed on one group of display units; therefore, a user can watch a plurality of 3D image signals and a plurality of 2D image signals at the same time, and the efficiency of obtaining image information by the user is improved; according to the system, the problems that atraditional 3D image display system is single in function, tedious in signal switching operation and the like are solved, and the working efficiency and the use experience of a user are greatly improved.

Owner:上海晨驭信息科技有限公司

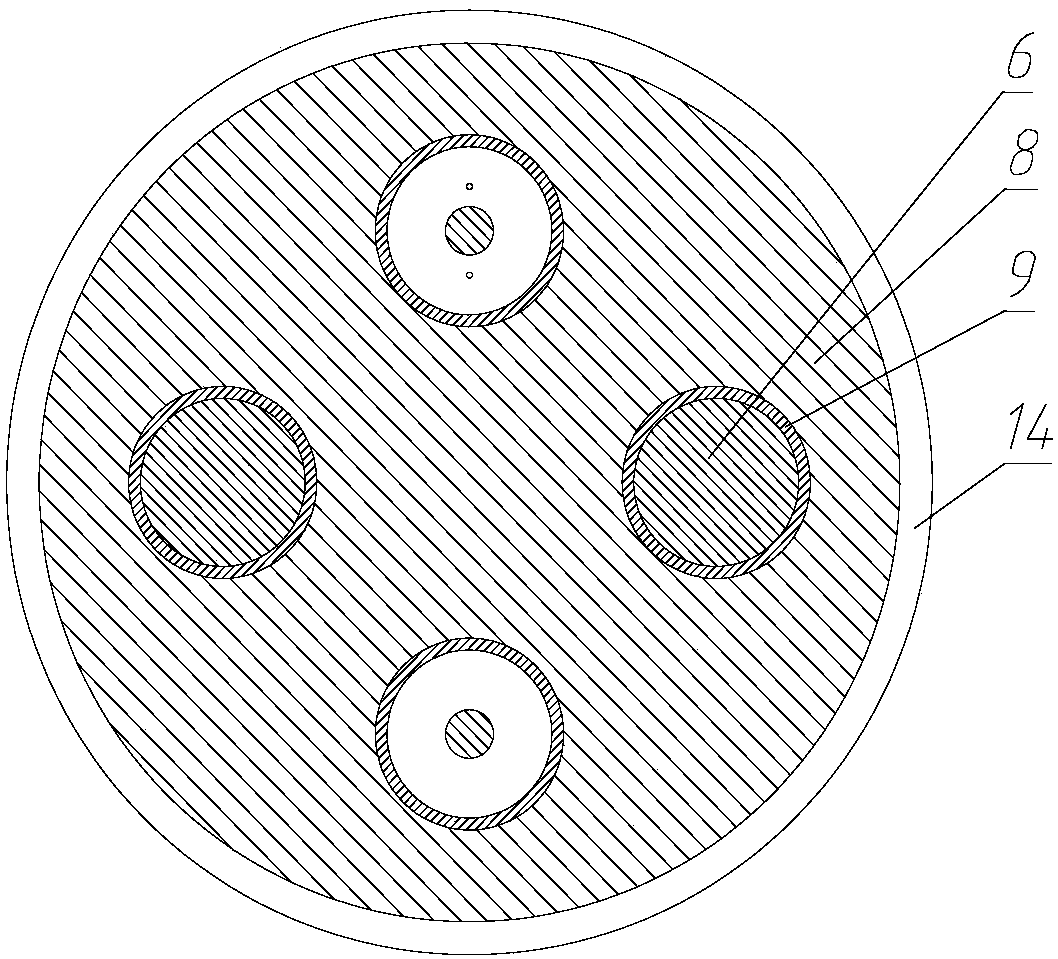

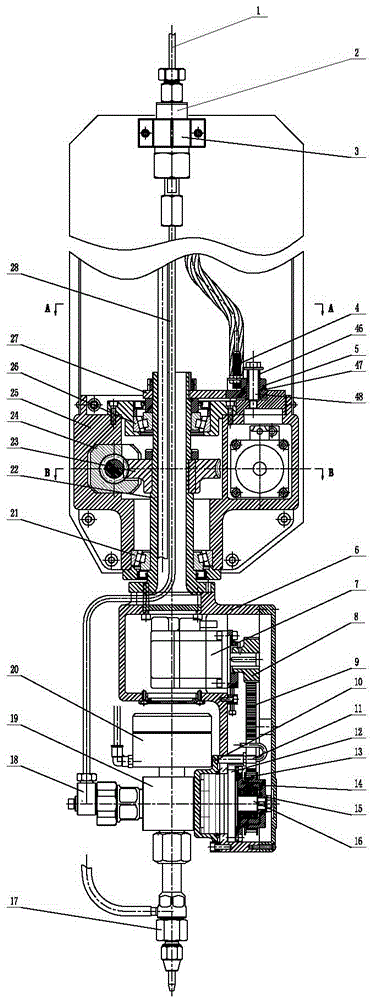

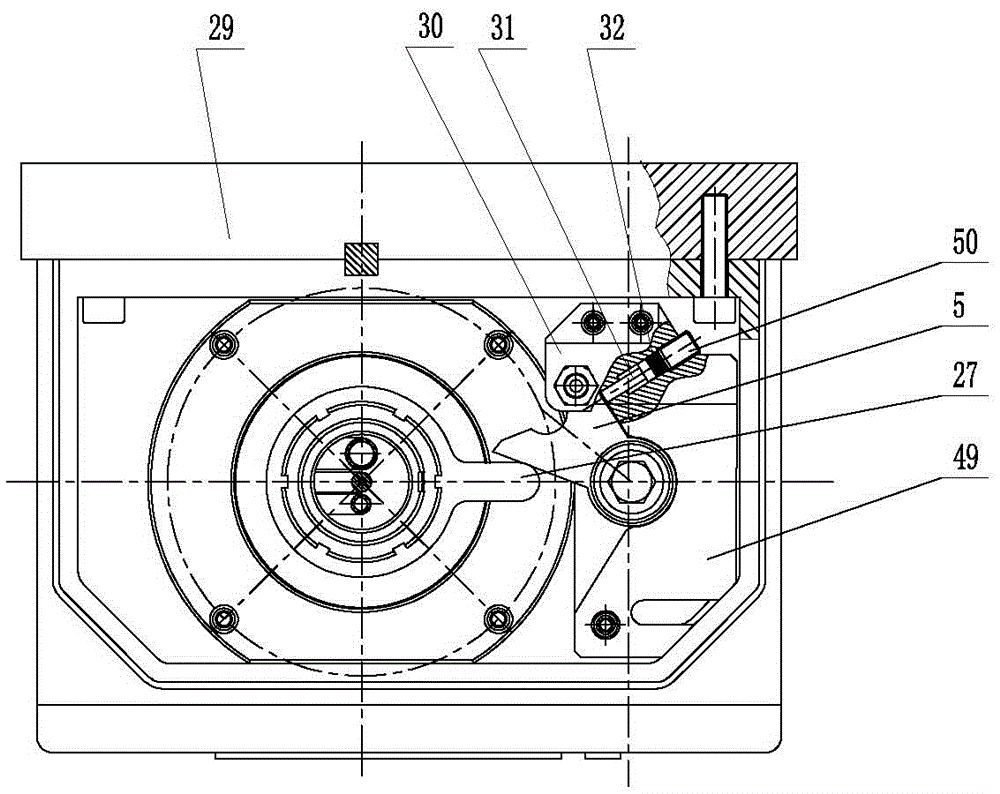

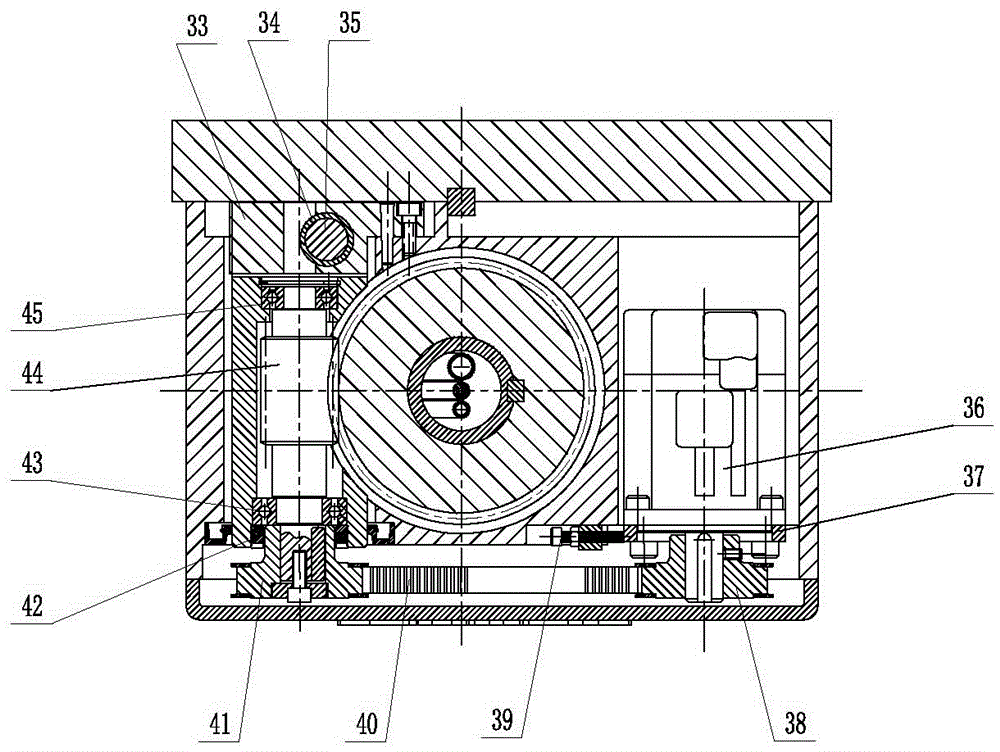

Attitude control device for five-axis waterjet head with horizontally installed swing axis

ActiveCN104238445BWon't interfereWide range of application requirementsNumerical controlVertical planeAttitude control

A five-axis water cutting head posture control device provided with a horizontally mounted swing shaft comprises a main shaft (22) and a water cutting head (17), wherein the main shaft (22) drives the water cutting head (17) to perform horizontal plane rotary motion, the main shaft (22) performs left and right, up and down as well as front and back three-dimensional motion under the driving of a driving mechanism, and the water cutting head (17) and a water switch (20) are mounted on a water switch base (19). The posture control device is characterized in that the water switch base (19) is mounted on an output shaft of a harmonic speed reducer (12) which is driven by a swing shaft servo motor (7), the harmonic speed reducer (12) drives the water cutting head (17) to perform deflection motion in a vertical plane, an included angle of an axis of the main shaft (22) and an axis of the output shaft of the harmonic speed reducer (12) is 90 degrees, and the maximum deflection angle of the output shaft of the harmonic speed reducer (12) is minus and plus 90 degrees. According to the five-axis water cutting head posture control device provided with the horizontally mounted swing shaft, the swing range is large, and the cutting accuracy is high.

Owner:DARDI INT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com