Scavenging machine for air-condition pipeline

A technology for air-conditioning ducts and cleaning machines, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inability to clean the inner wall of the pipeline, inconvenient cleaning, etc., and achieves superior functions, diversified connection equipment, and transmission smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

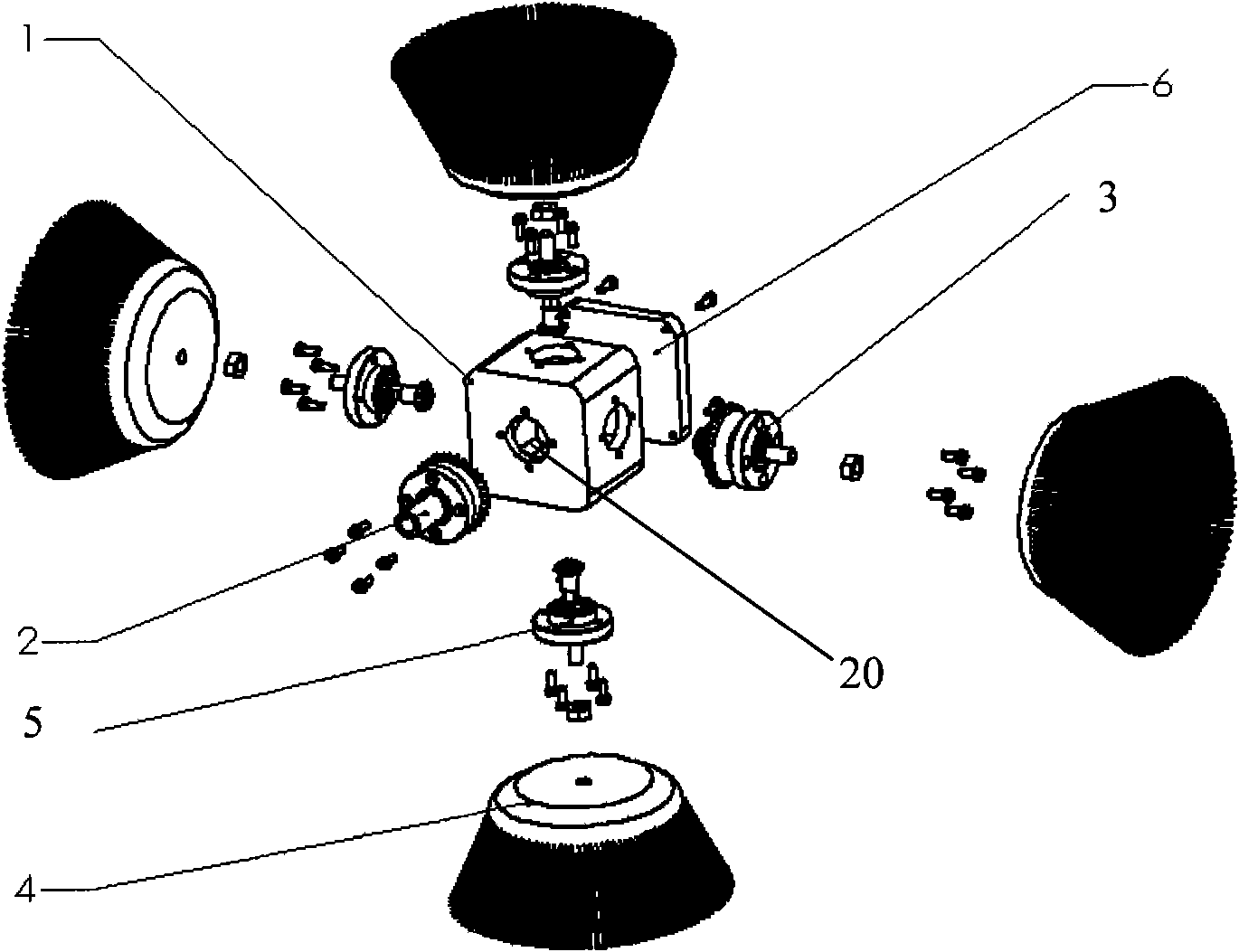

[0030] Such as figure 1 As shown, the air-conditioning duct cleaning machine of the present invention includes: a housing 1, a power input mechanism 2 accommodated in the housing 1, a first direction changing mechanism 3 and three second direction changing mechanisms 5, and installed on the first , the brush 4 on the second direction changing mechanism 3,5; the housing 1 is in the shape of a regular hexahedron, and is provided with a receiving space, and its five faces are correspondingly provided with mounting holes 20, and the other side is provided with a cover plate 6, which covers The plate 6 is arranged relative to the power input mechanism 2 .

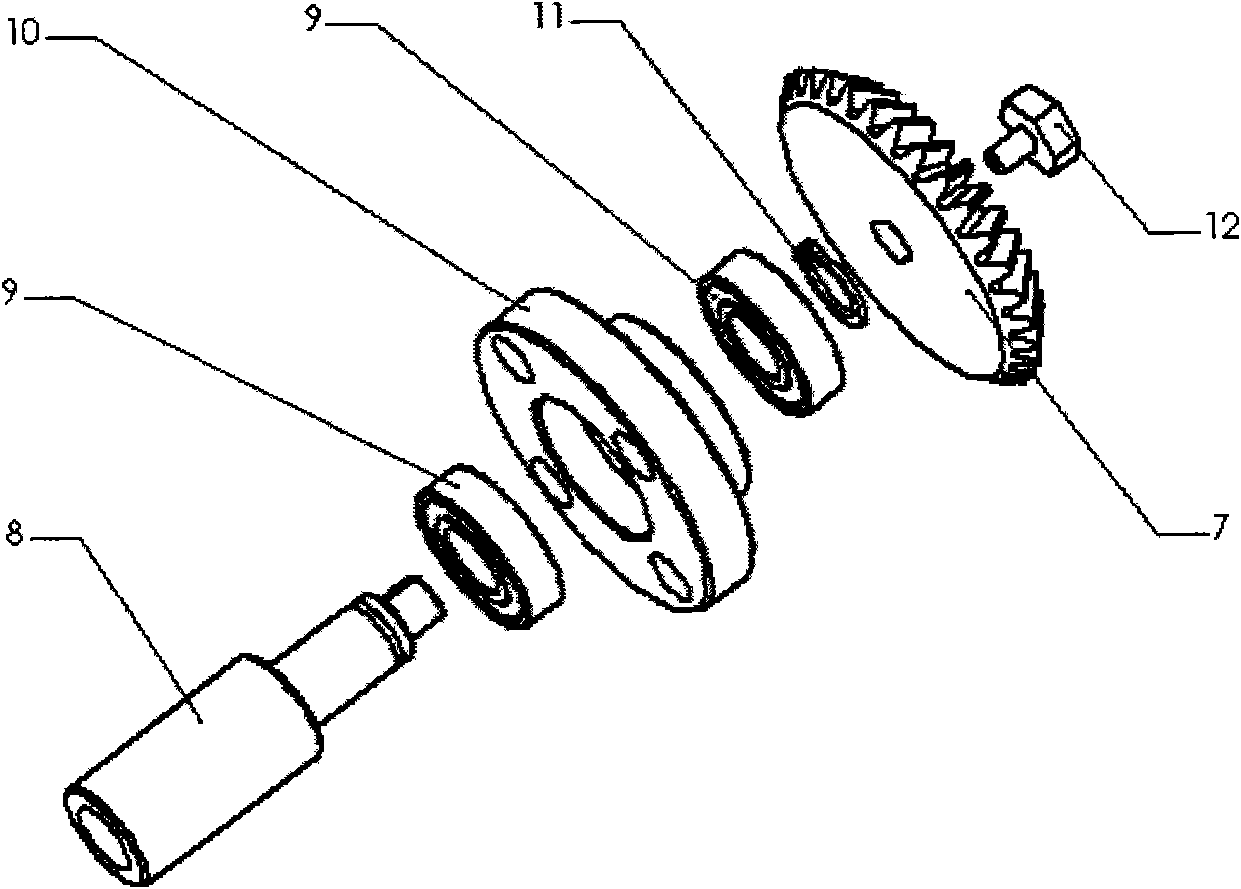

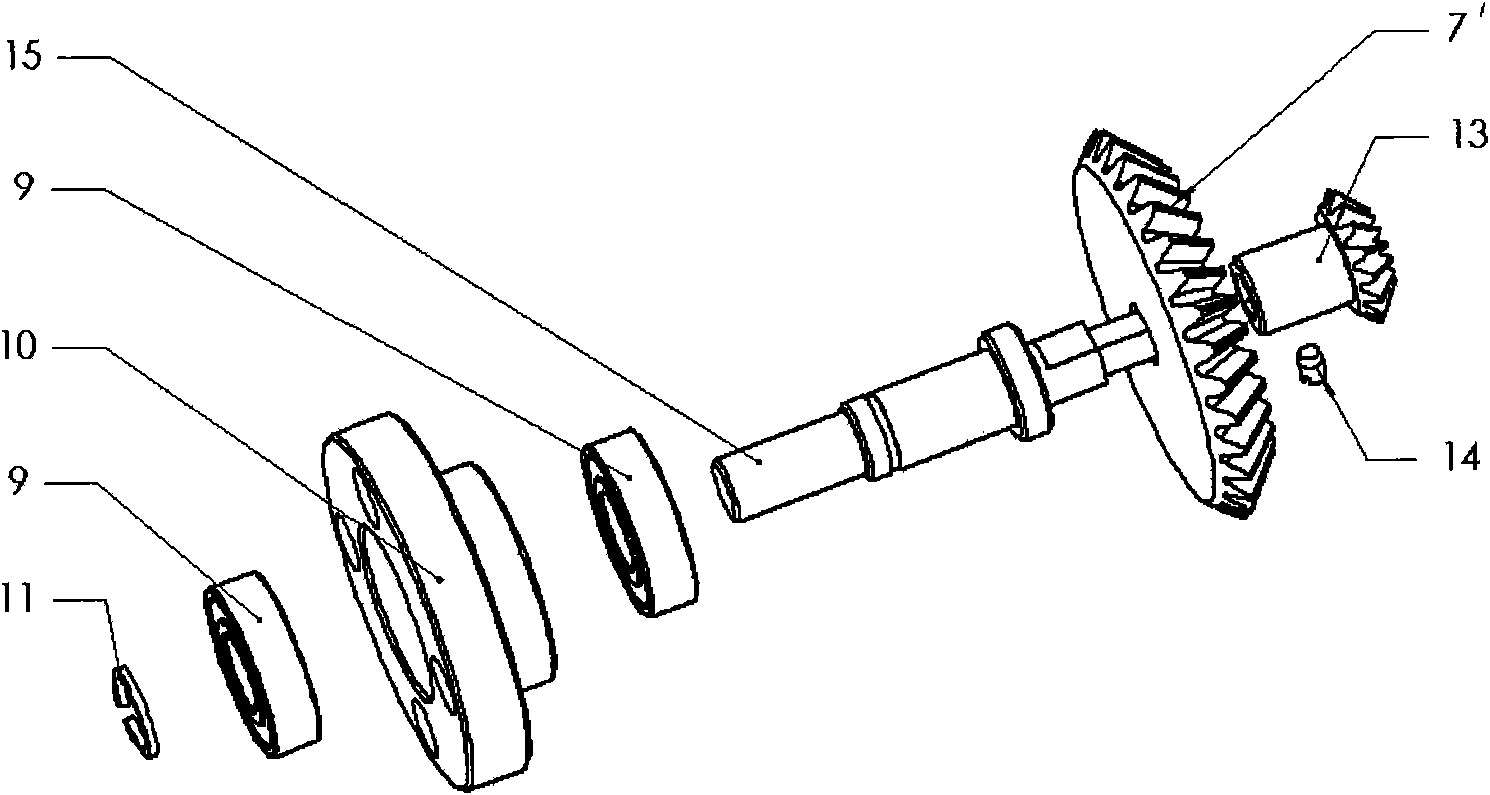

[0031] refer to figure 2 , the power input mechanism 2 includes an input shaft 8, two bearings 9, a support sleeve 10, and a first bevel gear 7 sleeved on the input shaft 8, and the inward end of the input shaft 8 is sequentially fitted with the bearing 9, the support sleeve 10, The other bearing 9 is fixed by the shaft retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com