Microstructure fiber sensor

A microstructure optical fiber and sensor technology, applied in the field of biochemical sensing, can solve the problems of not being able to meet the detection requirements, not being able to realize a large-scale measurement, and the detection range of SPR sensors being limited, etc., to achieve a simple and stable structure, and to solve the problem of sample packaging Difficult, Small Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

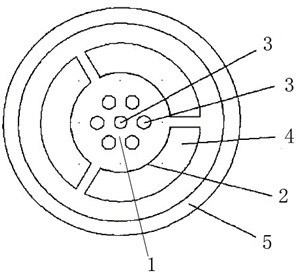

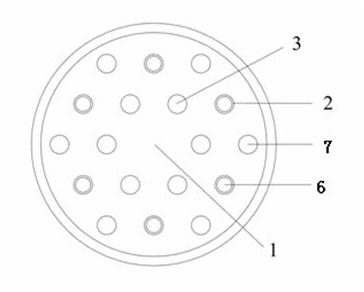

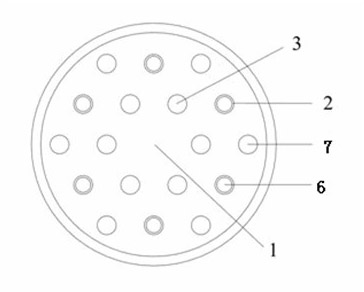

[0022] like figure 2 As shown, the core 1 of the microstructured optical fiber of the present invention is surrounded by two circles of air holes, wherein there are 12 air holes in the outer circle, 6 air holes 3 in the inner circle, 6 coated holes in the outer circle and non-coated holes in the outer circle The number of 7 is 6 respectively. The air holes in the inner ring and outer ring are arranged symmetrically with the center of the fiber core; the center points of the air holes in the outer ring are connected in a straight line to form a hexagon, and the center points of the air holes in the inner ring are connected in a straight line to form a hexagon . The hexagon of the line connecting the center points of the air holes of the outer ring is similar to and parallel to the hexagon of the line connecting the center points of the air holes of the inner ring. Both the coated hole 6 of the outer ring and the non-coated hole 7 of the outer ring are sample channels. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com