Preparation method and application of 1550 nm long wavelength vertical-cavity surface-emitting laser

A vertical cavity surface emission and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of hindering the development of long-wavelength VCSEL devices, difficult to realize and prepare current confinement layers, high reflectivity, etc., and achieve compact structure. , the demodulation speed is fast, the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

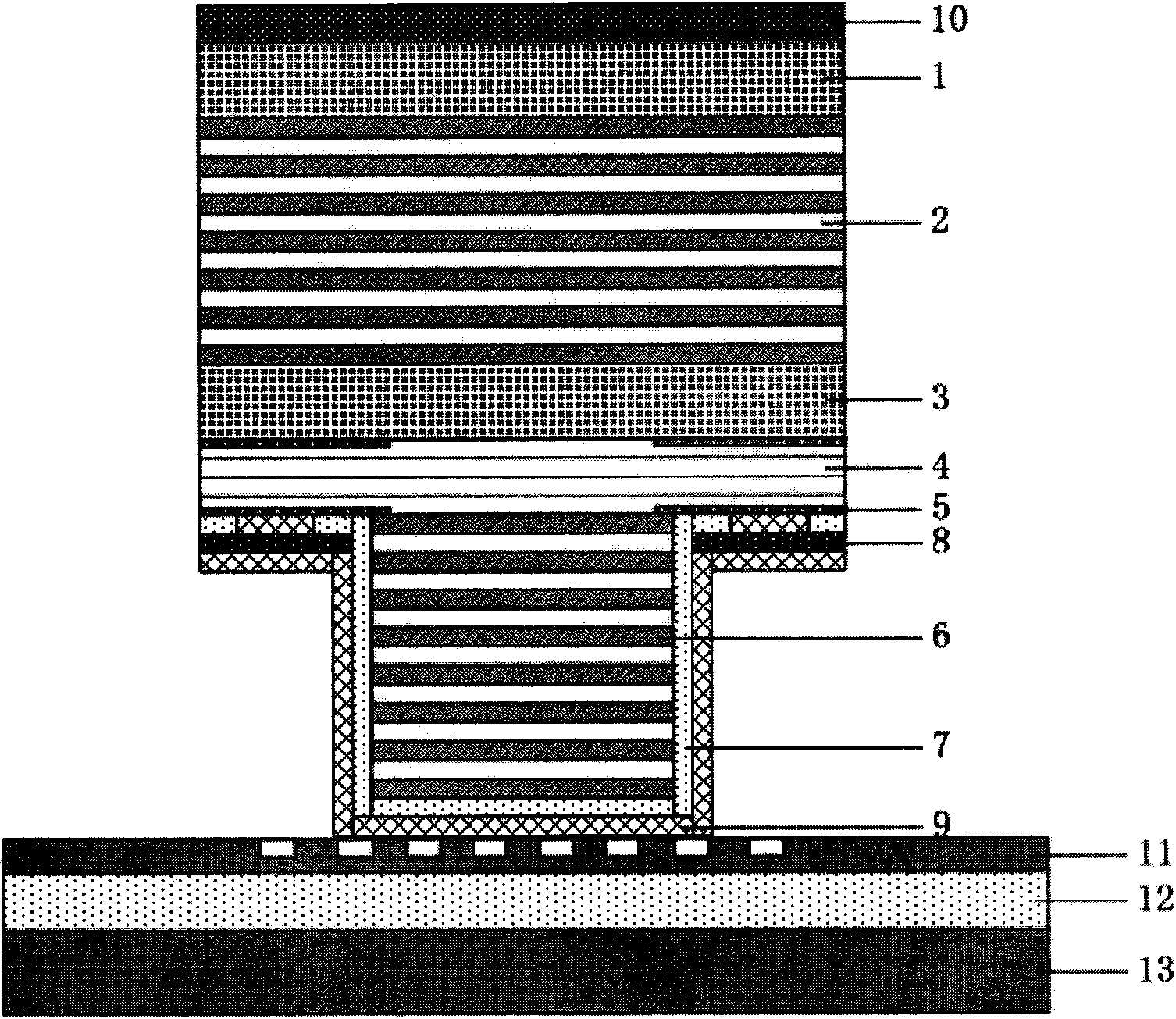

[0024] In the first step, the substrate (1), the N-type DBR (2), the extended InP layer (3), the active area and the epitaxial wafer of the P-type DBR (6) are prepared by the epitaxial growth method;

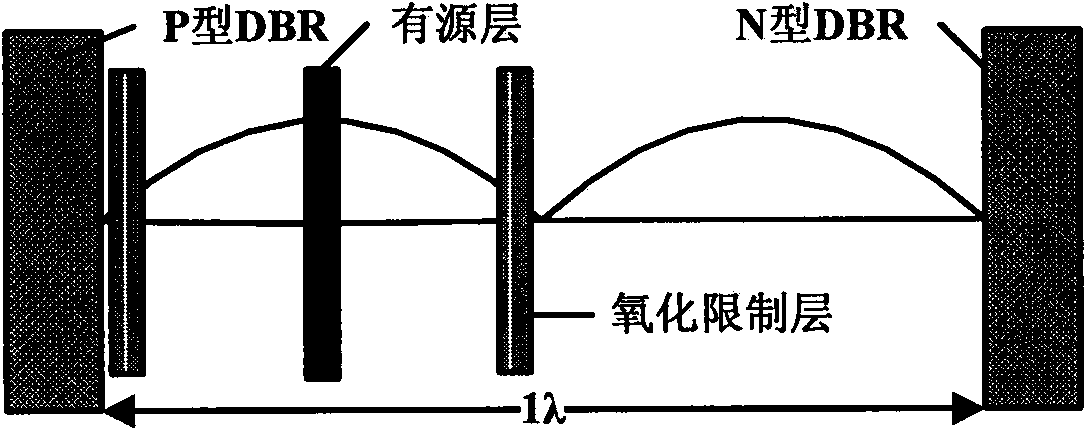

[0025] Prepare the InP substrate (1) and the extended InP layer (3), the thicknesses of which are about 500nm and 775nm, respectively; then use the epitaxial growth method to grow N-type alternately composed of 35 pairs of AlGaAsSb / AlAsSb materials with gradual composition DBR(2), which requires the use of photoresist as a mask for wet chemical etching of N-type DBR. From the formula L=λ / 4n, the thickness of AlGaAsSb and AlAsSb is set to 110nm and 125nm respectively; The graded 31 pairs of AlGaAsSb / AlAsSb alternately composed of N-type DBR (6) have the same material and thickness as the N-type DBR (2); the active area is composed of 3 pairs of InGaAsN / AlGaInAs QWs and two oxidation confinement layers, The cavity length of the resonant cavity is 1λ;

[0026] In the second step, photo...

Embodiment 2

[0034] A 1550nm long-wavelength vertical cavity surface emitting laser with InGaAsN / AlGaInAs quantum wells as the active layer, including sequentially connected InP substrate layers, N-type DBR, InP expansion layers, quantum well active gain layers QWs, oxidation confinement layers, P-type DBR (6), insulating layer SiO 2 And N-type and P-type metal electrodes. The multi-quantum well active gain layer QWs of the vertical cavity surface emitting laser resonator cavity is composed of InGaAsN / AlGaInAs material. Using the epitaxial growth method, P-type DBR and N-type DBR are grown by 31 pairs and 35 pairs of AlGaAsSb / AlAsSb materials with gradual composition. In this implementation case, photoresist is required as a mask, and wet chemical etching is performed on both the P-type DBR and the active area. Spin-coating photoresist on the top of the P-type DBR, and perform wet chemical etching on the P-type DBR and the active area to form a cylindrical mesa with the center of the N-typ...

Embodiment 3

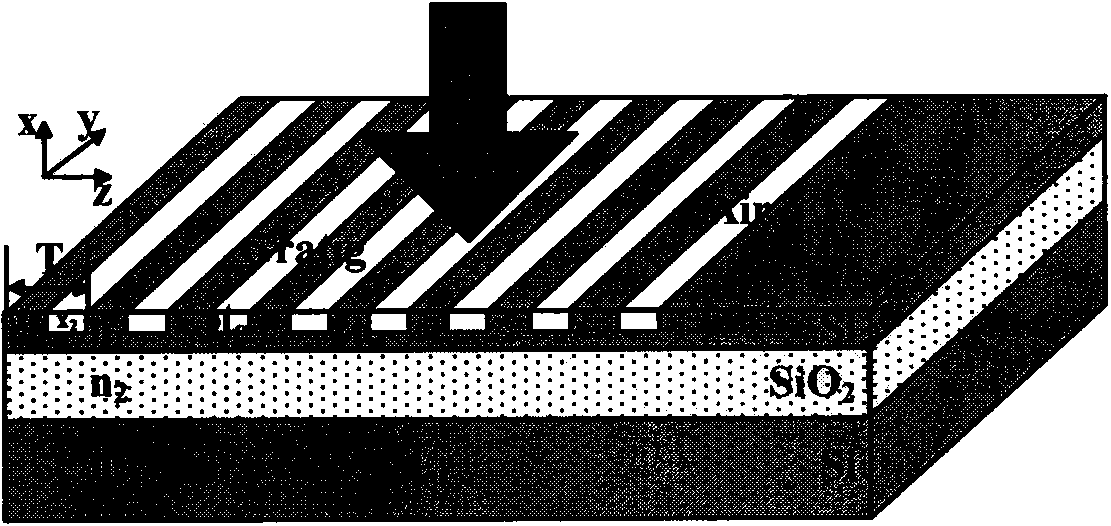

[0036] A 1550nm long-wavelength vertical cavity surface emitting laser with InGaAsN / AlGaInAs quantum wells as the active layer is used for integration with gratings. On the basis of embodiment 1 or 2, continue to be above the P-type mesa and on the left and right sides Re-deposit SiO by using PECVD method 2 . The SiO 2 The insulating layer can prevent the subsequent spin-coated BCB adhesive from damaging the metal electrode, so it has a good protective effect; finally on the device P-type DBR mesa, that is, SiO 2 BCB glue is applied to the top of the protective layer, which can then be connected with the grating part. The BCB layer can reduce the capacitance of the device, thereby not significantly reducing the high-frequency characteristics of the laser.

[0037] It should be noted that the above definition of each element is not limited to the specific structure, shape or size mentioned in the embodiments, and those skilled in the art can easily and well-known replacements in f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com