Vertical-cavity surface-emitting laser capable of automatically focusing

A vertical cavity surface emission and automatic focusing technology, which is applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem that the output power of the device is only in the order of milliwatts, the beam convergence is repeated, and the mechanical processing and assembly are complicated. and other problems, to achieve the effect of simple manufacturing process, easy promotion and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

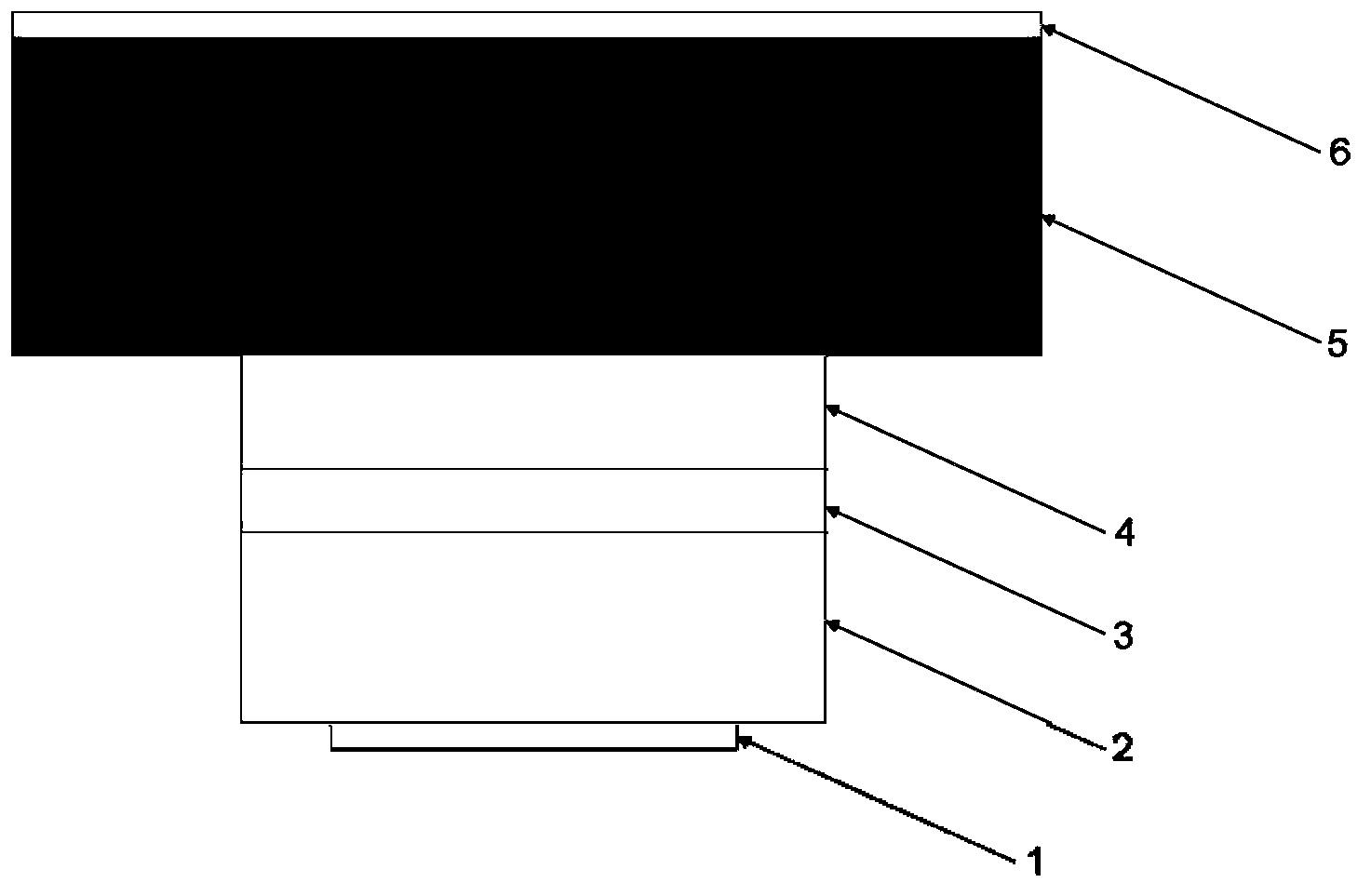

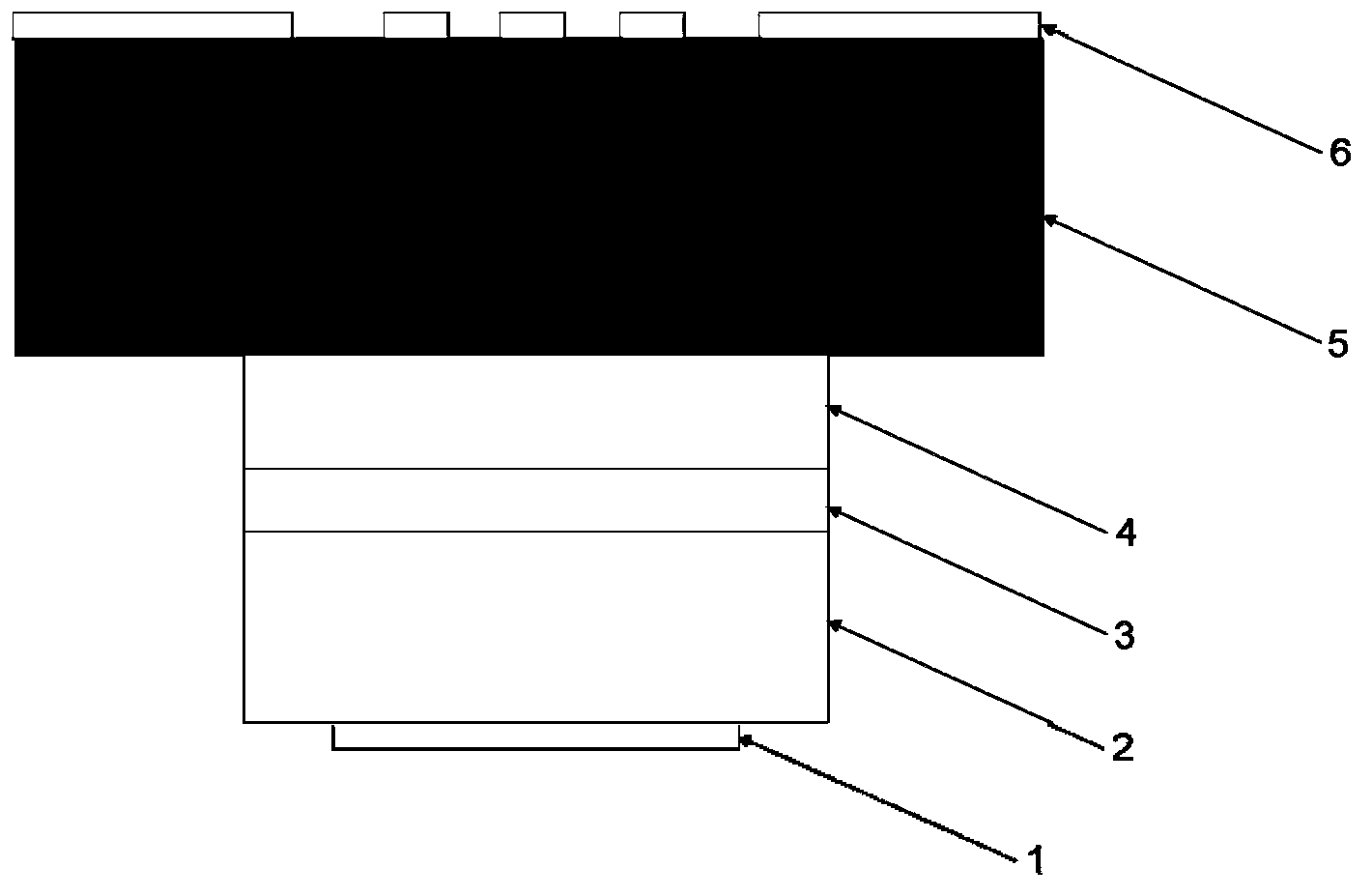

[0020] like Figure 1 to Figure 7 As shown, an autofocus vertical cavity surface emitting laser of the present invention includes: a lower electrode 1 , a P-type DBR layer 2 , an active layer 3 , an N-type DBR layer 4 , a substrate layer 5 and an upper electrode 6 . N-type DBR layer 4 is grown on the lower end of substrate layer 5 , and active layer 3 , P-type DBR layer 2 and lower electrode 1 are grown sequentially on the lower end of N-type DBR layer 4 . The upper electrode 6 is grown on the upper end surface of the substrate layer 5 . The lower electrode 1, the P-type DBR layer 2 and the active layer 3 jointly form a P-type semiconductor mesa.

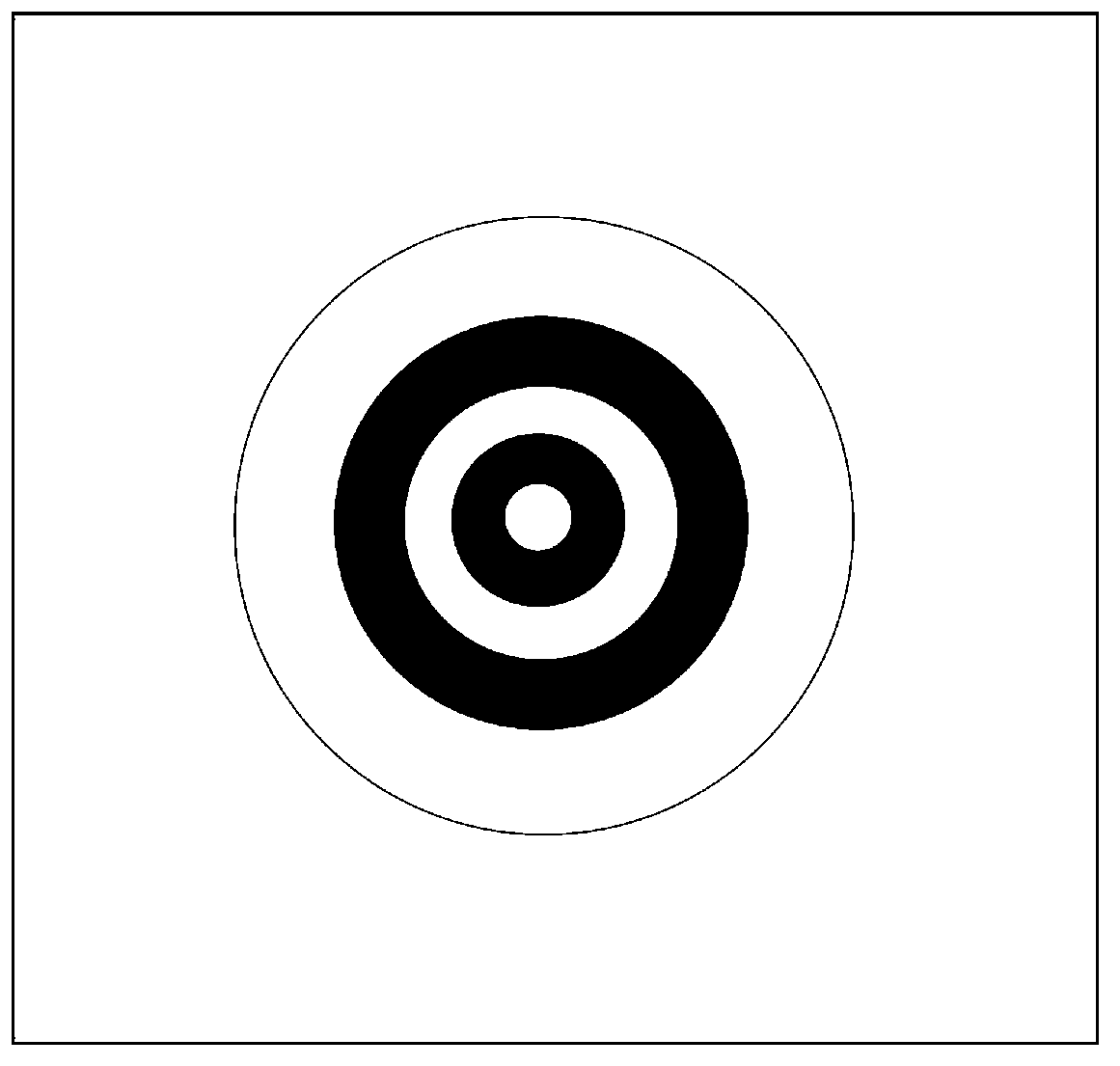

[0021] When making the laser according to the present invention: first utilize dry etching to process the shape of the P-type DBR layer 2 according to the expected spot shape, and when it is necessary to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com