Granulation method of microbial fertilizer

A technology of microbial fertilizer and microbial bacteria, which is applied in the direction of microbial treatment, fertilizer made from biological waste, and bio-organic part treatment, can solve the problems of poor fertilizer efficiency stability and short fertilizer efficiency maintenance time, so as to improve environmental tolerance, Guaranteed long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

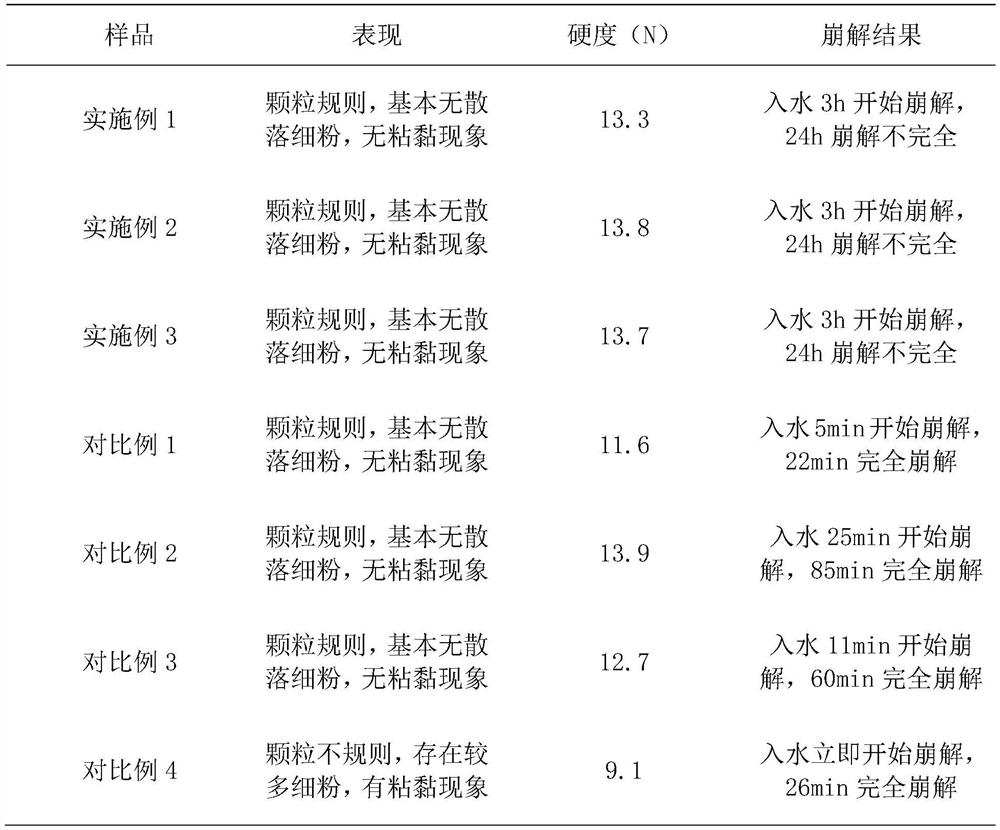

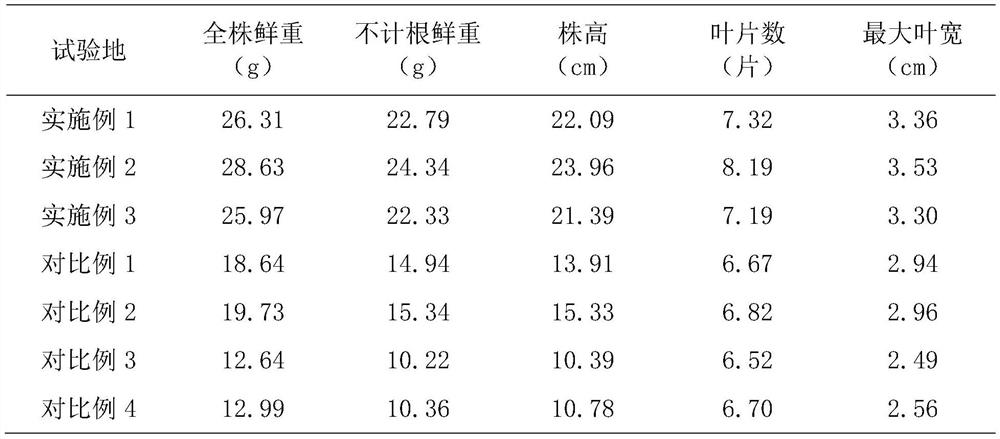

Embodiment 1

[0023] A method for granulating microbial fertilizer, the steps comprising:

[0024] Step 1: Carry out solid fermentation of the organic material containing microorganisms to obtain bacterial fertilizer, and then shape and granulate the bacterial fertilizer to obtain bacterial fertilizer granules, the microbial bacteria is Bacillus subtilis, and the organic material is cow dung;

[0025] The operation of solid fermentation is as follows: ferment under the ventilation condition of 0.4vvm ventilation, stir, aerate, naturally heat up, and ferment for 5 days under the conditions of controlling temperature at 35°C, oxygen content at 8%, and pH value at 6;

[0026] Step 2: Place the bacterial fertilizer particles in a steel wire ball mill for stirring to perform surface mechanical activation treatment;

[0027] Step 3: Prepare modified starch with a particle size of 0.01-1 μm and aerated concrete powder with a particle size of 50-70 μm respectively, mix the modified starch with the ...

Embodiment 2

[0032] A method for granulating microbial fertilizer, the steps comprising:

[0033] Step 1: Carry out solid fermentation of the organic material containing microbial bacteria to obtain bacterial fertilizer, and then shape and granulate the bacterial fertilizer to obtain bacterial fertilizer granules. The microbial bacteria is Bacillus natto, and the organic material is straw powder;

[0034] The operation of solid fermentation is as follows: ferment under the ventilation condition of 0.6vvm ventilation, stir, aerate, naturally heat up, and ferment for 4 days under the conditions of controlling temperature at 40°C, oxygen content at 12%, and pH value at 7;

[0035] Step 2: Place the bacterial fertilizer particles in a steel wire ball mill for stirring to perform surface mechanical activation treatment;

[0036] Step 3: prepare modified starch with a particle size of 1-2 μm and aerated concrete powder with a particle size of 100-120 μm, mix the modified starch and aerated concr...

Embodiment 3

[0041] A method for granulating microbial fertilizer, the steps comprising:

[0042] Step 1: Carry out solid fermentation of organic materials containing microbial bacteria to obtain bacterial fertilizer, and then mold and granulate the bacterial fertilizer to obtain bacterial fertilizer granules. The microbial bacteria are Bacillus licheniformis and Bacillus megaterium (mixed by equal weight), and the organic material is soybean meal;

[0043] The operation of solid fermentation is as follows: ferment under the ventilation condition of 0.8vvm ventilation, stir, aerate, naturally heat up, and ferment for 3 days under the conditions of controlling temperature at 45°C, oxygen content at 15%, and pH value at 8;

[0044] Step 2: Place the bacterial fertilizer particles in a steel wire ball mill for stirring to perform surface mechanical activation treatment;

[0045] Step 3: prepare modified starch with a particle size of 4-5 μm and aerated concrete powder with a particle size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com