Thermoelectric refrigeration auxiliary direct-current power transmission converter valve cooling system

A DC power transmission and thermoelectric refrigeration technology, applied in output power conversion devices, cooling/ventilation/heating renovation, electrical components, etc., can solve problems such as site constraints and bulky heat exchangers, improve construction efficiency and facilitate replacement. Simple, environmental tolerance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

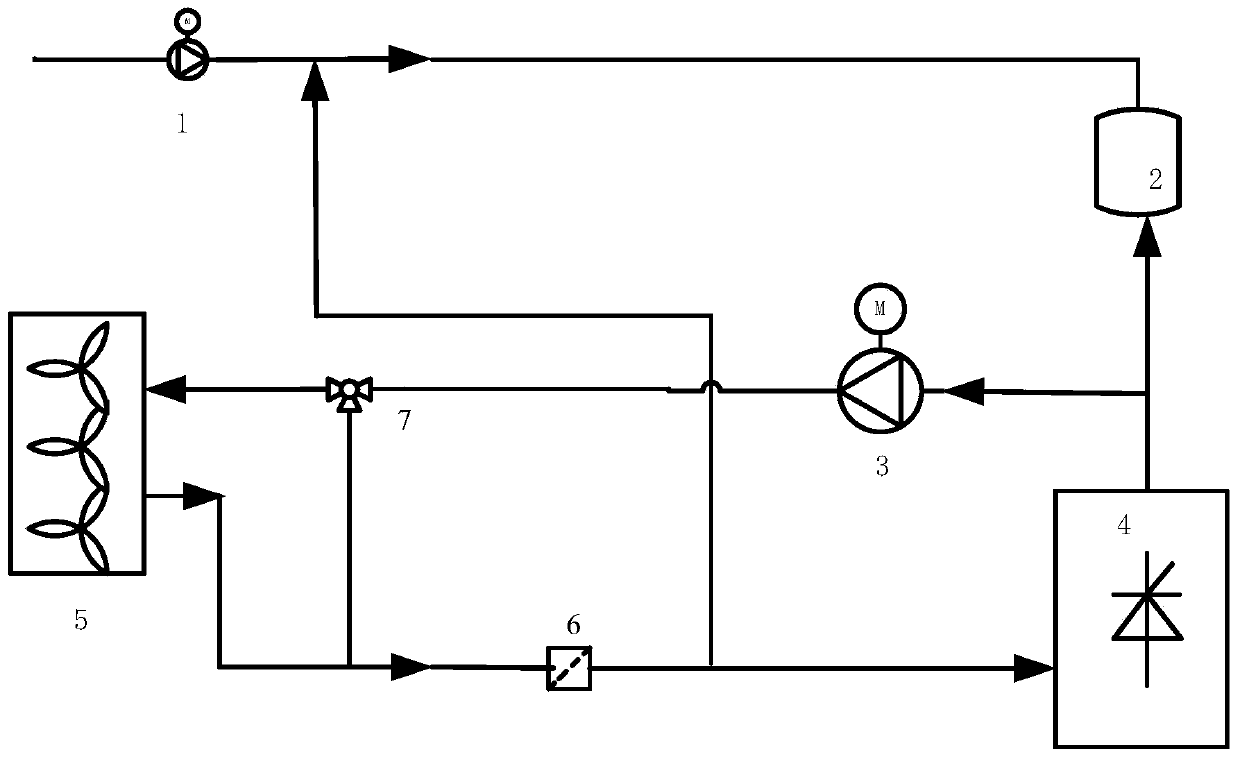

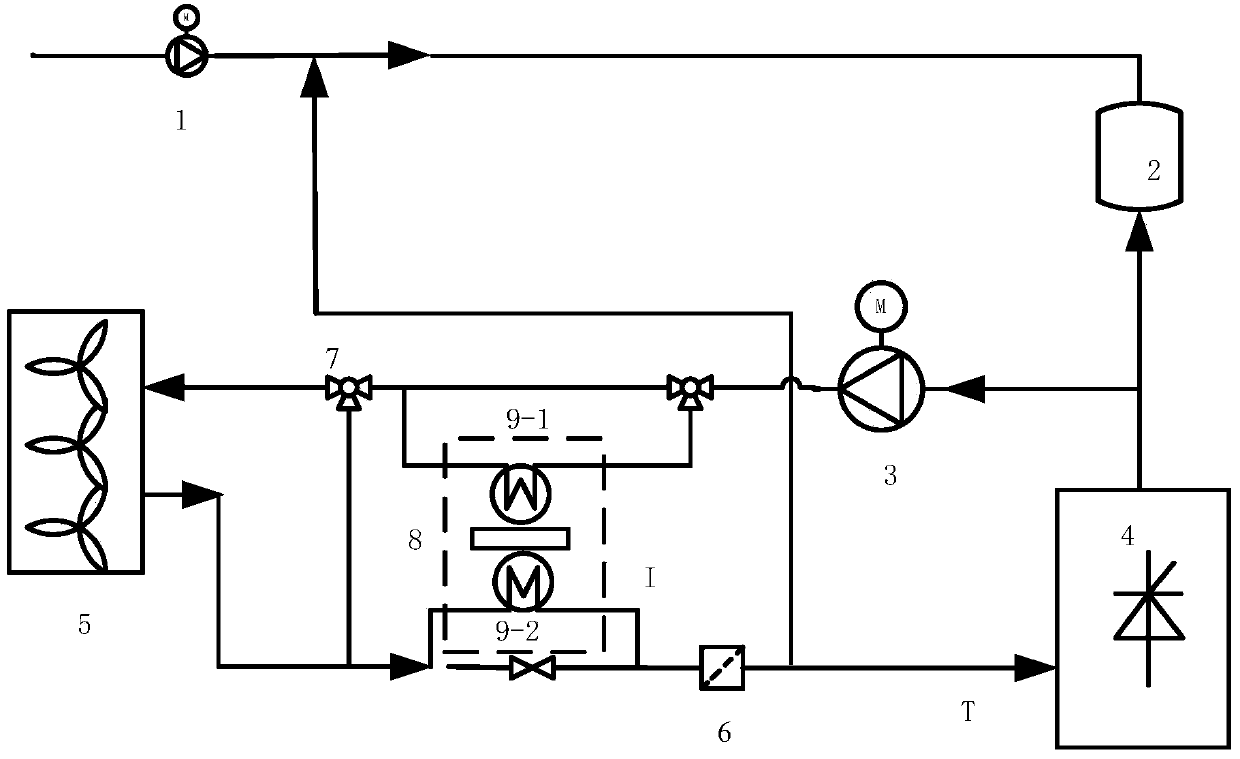

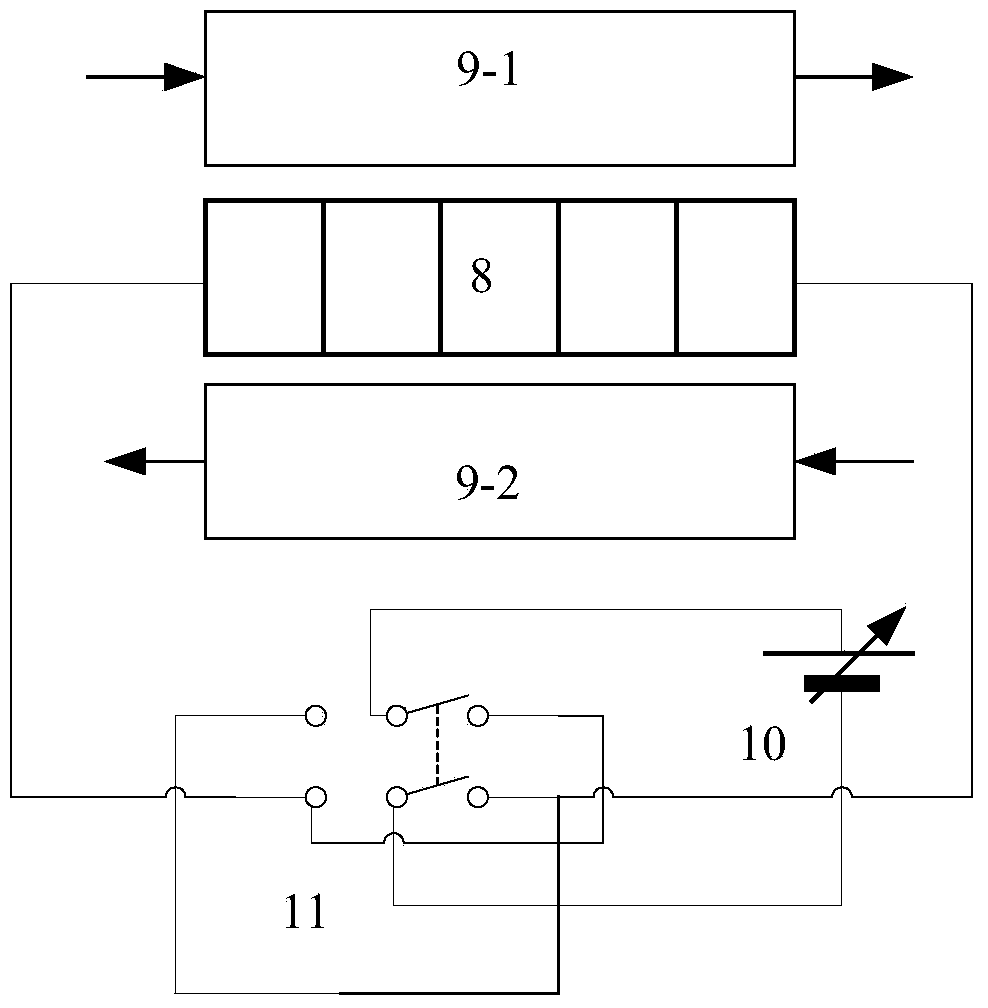

[0022] Such as figure 2 As shown, a thermoelectric refrigeration assisted DC transmission converter valve cooling system, which includes a water supply pump 1, a deionization system 2, a main circulating water pump 3, a converter valve 4, an air cooler 5, a main filter 6 and a tee Valve 7 also includes refrigeration galvanic couple stack 8, plate heat exchanger 9 and controllable DC power supply 10, such as image 3 As shown, the cooling couple stack 8 and the controllable DC power supply 10 form a closed loop, the hot end of the cooling couple stack is connected to the water outlet of the converter valve through the plate heat exchanger 9-1, and the cold end of the cooling couple stack It is connected with the water inlet end of the diverter valve through the plate heat exchanger 9-2.

[0023] In order to better realize the present invention, the thermoelectric cooling assisted direct current transmission converter valve cooling system further includes a commutator 11 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com